Mechanically Organizing Bottles

Title: Mechanically Organizing Bottles: Streamlining Efficiency in Modern Industries

Meta Description: Discover how mechanical bottle organization systems revolutionize efficiency, accuracy, and workflow in industries like food & beverage, pharmaceuticals, and recycling.

Introduction

In fast-paced industrial environments, the organization of bottles—whether empty or filled—can dictate production speed, safety, and profitability. Mechanically organizing bottles eliminates human error, accelerates workflows, and adapts to high-volume demands. From beverage bottling plants to pharmaceutical labs, automation is reshaping how businesses handle containers. This article explores the technology behind mechanical bottle organization, its benefits, and practical applications across industries.

What is Mechanical Bottle Organization?

Mechanical bottle organization involves automated systems designed to sort, arrange, transport, and store bottles with minimal human intervention. These systems replace manual labor with precision-engineered machinery, such as:

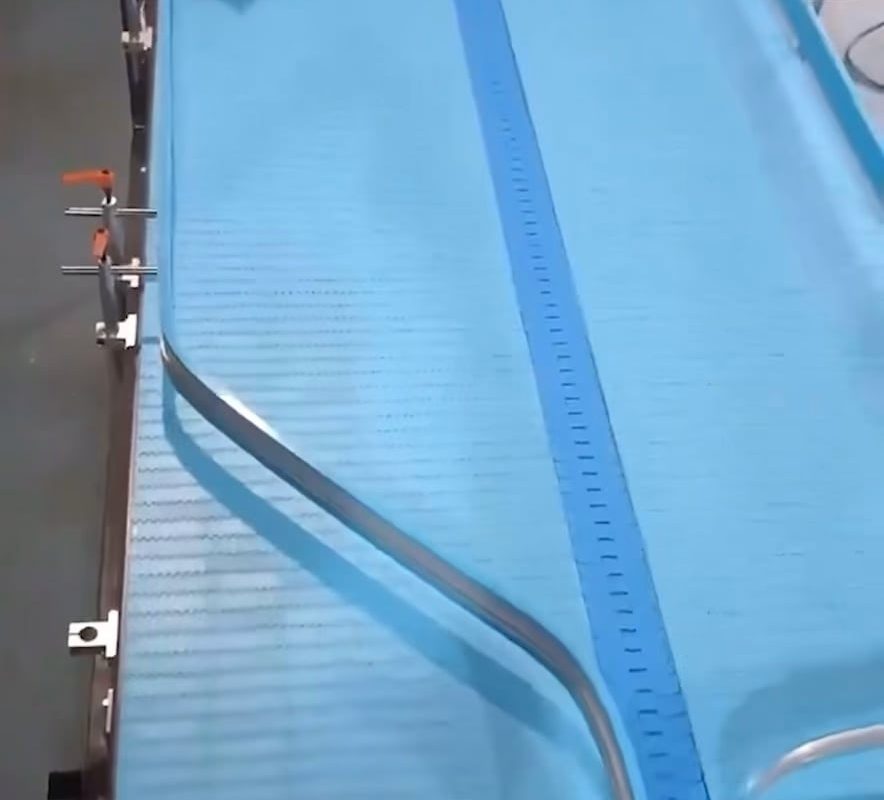

- Conveyor Belts: Transport bottles between production stages.

- Automated Palletizers: Stack bottles onto pallets for storage/shipping.

- Robotic Arms: Pick and place bottles with millimeter accuracy.

- Optical Sorting Machines: Classify bottles by size, shape, or material using cameras and AI.

These technologies work seamlessly to handle materials like glass, plastic, or metal across diverse environments.

Key Benefits of Mechanized Systems

1. Unmatched Speed & Scalability

Automated systems can process thousands of bottles per hour, far exceeding manual capabilities. This scalability supports business growth without proportional labor increases.

2. Enhanced Accuracy & Quality Control

Machines reduce misalignment, breakage, and labeling errors. Integrated sensors detect defects (e.g., cracks or incorrect fill levels), ensuring consistent product quality.

3. Cost Efficiency

While initial investments are high, automation slashes long-term labor costs and operational downtime. ROI is achieved through faster throughput and reduced waste.

4. Worker Safety

Heavy lifting and repetitive motions are delegated to machines, lowering workplace injury risks. Employees shift to supervisory or technical roles, boosting job satisfaction.

5. Sustainability

Automated sorting systems excel in recycling facilities, precisely separating bottles by material (PET, HDPE, etc.) to support circular economies.

Applications Across Industries

Food & Beverage

- Filling lines use conveyor belts to move bottles through washing, filling, capping, and labeling stations.

- Robotic palletizers prepare cases for distribution.

Pharmaceuticals

- Sterile environments rely on automated systems to handle sensitive vials and avoid contamination.

- Precision sorting ensures compliance with strict regulatory standards.

Cosmetics & Chemicals

- Delicate perfume or chemical bottles require gentle handling, achieved via soft-grip robotics.

Recycling Facilities

- Optical sorters identify and separate bottles by color/polymer type, improving recycling purity rates.

Choosing the Right Mechanical Organization System

Consider these factors:

- Bottle Characteristics: Size, weight, material, and fragility dictate system design.

- Production Volume: High-speed systems suit mass production; modular setups adapt to smaller batches.

- Integration: Ensure compatibility with existing machinery (e.g., filling or packaging equipment).

- Maintenance: Opt for systems with self-diagnostics and easy-access parts to minimize downtime.

Future-ready systems may incorporate AI-driven predictive maintenance or IoT connectivity for real-time monitoring.

Conclusion

Mechanical bottle organization is no longer a luxury—it’s a necessity for industries competing on efficiency and quality. By automating sorting, handling, and storage, businesses reduce costs, enhance safety, and meet sustainability goals. As technology advances, these systems will grow smarter, leaner, and more accessible, paving the way for next-generation manufacturing and recycling.

Call to Action: Ready to optimize your bottle workflow? Consult an automation specialist to design a tailored mechanical organization solution today!

Keywords for SEO:

automated bottle organization, mechanical bottle sorting, bottle handling systems, industrial bottle automation, robotic palletizing, bottle conveyor systems, recycling sorting machines, pharmaceutical bottle handling.

Optimize your content strategy with this guide and stay ahead in the automation revolution!