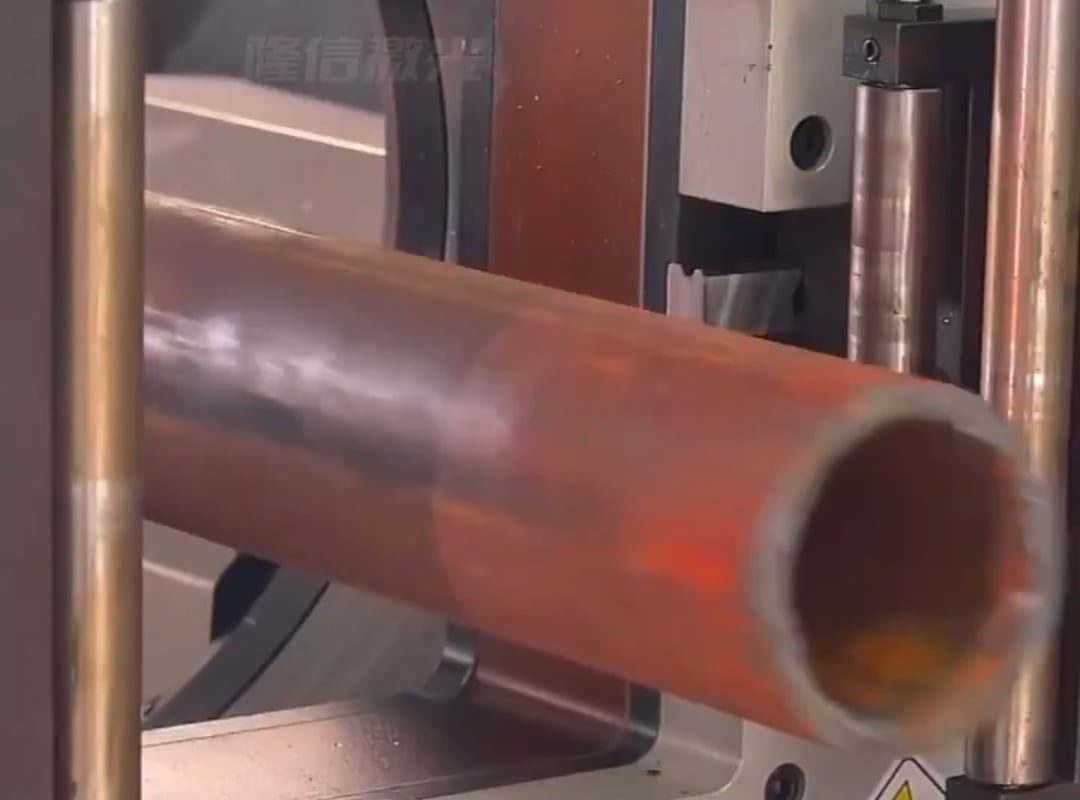

Using laser to cut a pipe

Title: Precision & Efficiency: The Ultimate Guide to Laser Cutting Pipes

Meta Description: Discover how laser cutting technology revolutionizes pipe fabrication. Learn about its benefits, applications, and best practices for flawless results.

Why Laser Cutting is Transforming Pipe Fabrication

Laser cutting has emerged as a game-changer in metalworking, especially for industries that rely on precise pipe fabrication. From construction and automotive manufacturing to aerospace and energy sectors, laser-cut pipes deliver unmatched accuracy, speed, and versatility. Unlike traditional methods like sawing or plasma cutting, lasers use concentrated beams to slice through materials with microscopic precision, minimizing waste and reducing production timelines.

In this guide, we’ll explore how laser cutting works for pipes, its advantages, key applications, and tips for choosing the right service provider.

How Does Laser Cutting Work for Pipes?

Laser cutting uses a high-powered beam—delivered via fiber, CO2, or solid-state lasers—to melt, burn, or vaporize material along a programmed path. For pipes, specialized rotary attachments hold the cylindrical workpiece in place while the laser head moves around its surface. Advanced software (like CAD/CAM) maps the design and adjusts for the pipe’s curvature, ensuring precise cuts, holes, or complex patterns.

Key Benefits of Laser-Cut Pipes

- Pinpoint Accuracy: Achieve cuts within 0.1mm tolerances, critical for fittings, joints, and structural integrity.

- Minimal Material Waste: Nesting software optimizes layouts to maximize material usage.

- No Tool Wear: Non-contact cutting eliminates blade degradation, reducing long-term costs.

- Smooth Finishes: Lasers produce burr-free edges, often eliminating post-processing steps.

- Versatility: Cut stainless steel, aluminum, copper, plastics, and more in diameters from 1mm to 300mm+.

Industries Using Laser-Cut Pipes

From micro-tubing in medical devices to heavy-duty pipelines, laser-cut pipes serve diverse needs:

- Oil & Gas: Drill pipes, hydraulic systems, and custom fittings.

- Automotive: Exhaust systems, fuel lines, and chassis components.

- Aerospace: Lightweight hydraulic tubing and engine parts.

- Architecture: Decorative railings, handrails, and structural elements.

- Medical: Hypodermic needles, implantable devices, and fluid transfer systems.

The Laser Cutting Process for Pipes: Step-by-Step

- Design: CAD models define dimensions, angles, and cutouts.

- Setup: The pipe is secured in a rotary chuck, calibrated for consistent rotation.

- Cutting: The laser traces the design while adjusting focus for the pipe’s curvature.

- Finishing: Debris is removed via gas assist (nitrogen/oxygen), and edges are smoothed.

- Quality Check: Optical scanners verify dimensional accuracy.

Choosing a Laser Pipe Cutting Service

If outsourcing, prioritize providers with:

- Pipe-Specific Expertise: Experience handling your material and diameter.

- Advanced Equipment: Fiber lasers (for metals) or CO2 lasers (for plastics/composites).

- Quality Assurance: ISO 9001 or AS9100 certifications, along with post-cut inspections.

- Scalability: Capacity for high-volume orders or rapid prototyping.

Future Trends: Automation & Sustainability

Laser cutting is evolving with Industry 4.0 integration. Automated loading/unloading systems, AI-powered defect detection, and energy-efficient lasers now reduce operational costs and environmental impact. Expect further innovations in speed and 3D laser cutting for complex tubular geometries.

Conclusion

Laser cutting offers an unparalleled blend of precision, efficiency, and flexibility for pipe fabrication. Whether you’re crafting intricate medical components or industrial-scale pipelines, this technology ensures consistency, durability, and cost savings. As lasers grow faster and smarter, they’ll remain indispensable in the manufacturing landscape.

Ready to adopt laser-cut pipes? Evaluate suppliers based on their technical capabilities, certifications, and commitment to innovation.

Target Keywords:

- Laser cutting pipe

- Precision pipe cutting

- Industrial laser cutting services

- Pipe fabrication technology

- Laser-cut tubing applications

Optimization Tips:

- Use headers (H2/H3) with keywords.

- Link to related resources (e.g., “types of laser cutters”).

- Add images/videos of laser-cut pipes with alt text.