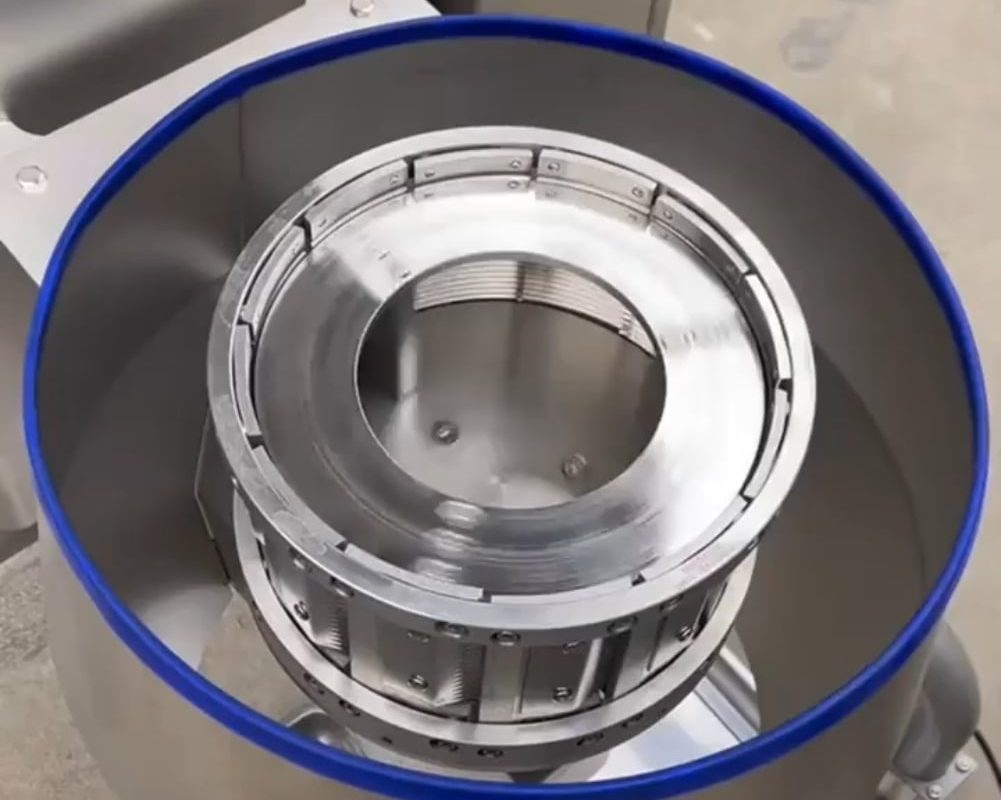

Centrifuge shredder

Unlocking Efficiency in Material Processing: The Power of Centrifuge Shredders

In industries where material reduction, recycling, or waste management is paramount, the centrifuge shredder stands out as a revolutionary solution. Combining brute force with precision engineering, these machines transform bulky materials into manageable, reusable particles with remarkable efficiency. This guide explores how centrifuge shredders work, their applications, benefits, and key considerations for choosing the right system for your operations.

What Is a Centrifuge Shredder?

A centrifuge shredder (also called a centrifugal shredder) is a heavy-duty industrial machine designed to shred, grind, or pulverize materials using high-speed rotational force. Unlike traditional shredders that rely solely on blades cutting against stationary materials, centrifuge models use centrifugal force to “throw” materials outward against grinding surfaces, hammers, or blades. This dual-action approach maximizes shredding power, enabling faster processing of challenging materials like:

- Tires and rubber

- Plastics and polymers

- E-waste (circuit boards, cables)

- Hazardous waste (chemical drums, contaminated materials)

- Organic biomass (wood, agricultural waste)

How Do Centrifuge Shredders Work?

The shredding process leverages physics for optimal results:

- Material Feeding: Input is loaded into a central chamber.

- High-Speed Rotation: A rotor spins at intense speeds (often 500–1,500 RPM), generating centrifugal force.

- Forced Impact: Material is flung outward against stationary shredding elements (teeth, blades, or screens).

- Size Reduction: Repeated impacts and shearing break down materials into uniform particles.

- Output Control: Adjustable screens or classifiers ensure particles meet desired size specifications.

This dynamic process minimizes jamming, reduces energy consumption, and extends equipment lifespan compared to conventional shredders.

Key Benefits of Centrifugal Shredding Technology

- Exceptional Efficiency

- Centrifugal force amplifies shredding power, reducing processing time by up to 40% compared to single-shaft shredders.

- Reduced Downtime

- Fewer moving parts and self-cleaning designs lower maintenance needs and prevent clogging.

- Energy Savings

- Faster processing translates to lower energy costs per ton of material processed.

- Versatility

- Handles diverse materials, from brittle plastics to fibrous textiles, without retooling.

- Precision Output

- Customizable screen sizes ensure consistent particle sizes for recycling or disposal compliance.

Top Industrial Applications

Centrifuge shredders are indispensable across sectors:

- E-Waste Recycling: Shred circuit boards and cables to recover precious metals safely.

- Tire Recycling: Reduce whole tires to crumb rubber for asphalt, playgrounds, or industrial fuel.

- Plastic Reprocessing: Create uniform flakes for pelletizing or 3D printing feedstock.

- Waste-to-Energy: Prepare biomass or municipal solid waste (MSW) for incineration or gasification.

- Hazardous Waste Destruction: Securely shred contaminated containers or chemicals to meet EPA regulations.

Types of Centrifuge Shredders

- Horizontal Centrifuge Shredders

- Ideal for high-volume processing; materials flow horizontally through the chamber.

- Vertical Centrifuge Shredders

- Compact footprint; gravity aids material flow in downward cycles.

- Hammer Mill Variants

- Combine centrifugal force with swinging hammers for ultra-fine grinding.

Choosing the Right Centrifuge Shredder: A Quick Buyer’s Guide

- Material Type

- Hard, abrasive materials (metals, tires) require tungsten carbide-tipped blades.

- Soft materials (plastics, foam) suit standard alloy steel blades.

- Capacity Needs

- Match rotor size (20–100+ HP motors) and feed hopper design to your daily volume.

- Output Goals

- Define target particle size (e.g., 10mm chips vs. 2mm powder) to select appropriate screen mesh.

- Safety & Compliance

- Look for dust suppression systems, explosion-proofing, and noise reduction features.

- Scalability

- Modular designs allow future upgrades for changing operational demands.

Conclusion: Transforming Waste into Opportunity

Centrifuge shredders are reshaping industrial material processing, offering unmatched speed, adaptability, and cost-efficiency. Whether you’re recycling e-waste, managing hazardous byproducts, or preparing raw materials for reuse, this technology empowers businesses to meet sustainability goals while boosting profitability.

Ready to upgrade your shredding process? Consult with leading manufacturers to tailor a centrifuge shredder system to your unique needs—and unlock the next level of operational excellence.

Keywords: Centrifuge shredder, centrifugal shredder, industrial shredder, waste processing, tire recycling, e-waste shredder, material reduction, recycling equipment.

Meta Description: Discover how centrifuge shredders revolutionize material processing. Learn their benefits, applications, and how to choose the right model for waste recycling, e-waste, plastics, and more.