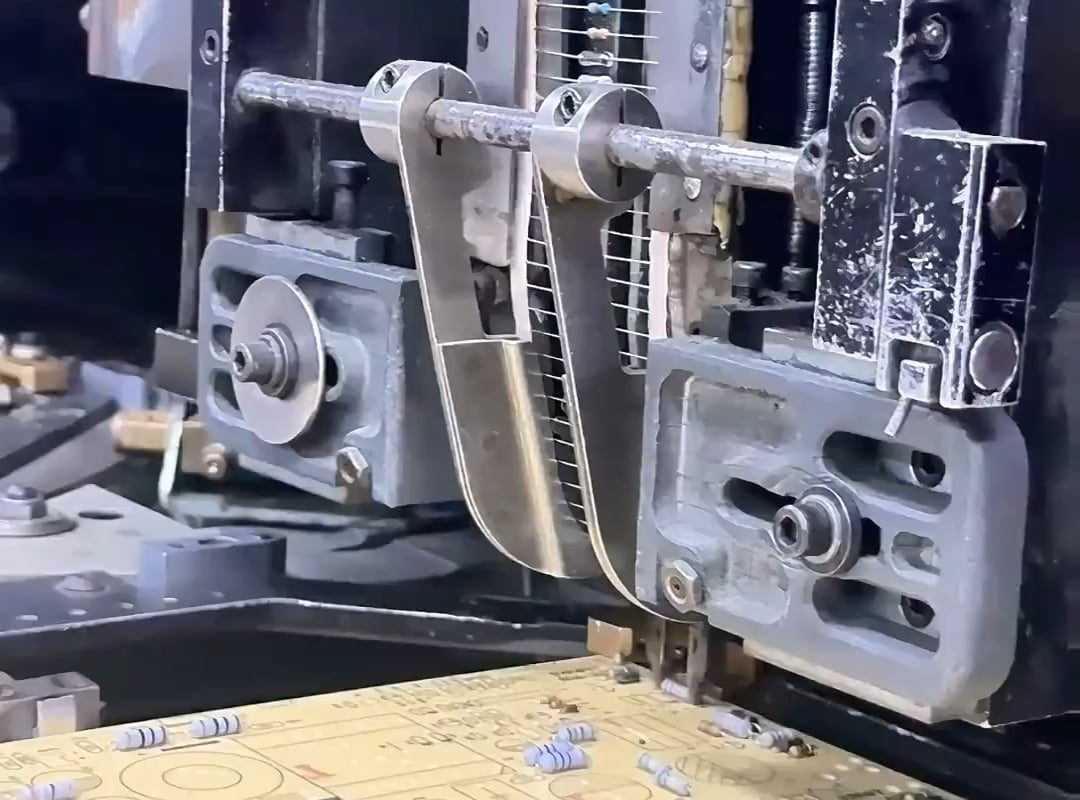

A rapid PCB assembly process in action

Title: A Rapid PCB Assembly Process in Action: How Cutting-Edge Tech Delivers Speed Without Sacrificing Quality

Meta Description: Discover how a rapid PCB assembly process works in real-time, leveraging automation, advanced machinery, and optimized workflows to slash production time while ensuring precision.

In the fast-paced world of electronics manufacturing, rapid PCB assembly is the golden ticket for startups, innovators, and enterprises racing to bring products to market. But how does this accelerated process actually work behind the scenes? In this article, we’ll demystify the journey of a PCB from raw materials to a fully functional board—in record time—and explore the technologies, strategies, and benefits driving this revolution.

What Makes Rapid PCB Assembly Possible?

The speed of modern PCB assembly hinges on three pillars: automation, smart workflows, and experienced engineering teams. Here’s what happens when these elements converge:

1. Design Optimization for Speed (DFM)

Before assembly begins, engineers review the PCB design for manufacturability (DFM). Using AI-powered software, they flag potential issues—like component spacing errors or thermal imbalances—that could slow down production. Resolving these upfront prevents delays during assembly.

2. Component Sourcing: Agile Supply Chains

Rapid assembly partners leverage global supplier networks and real-time inventory tracking to secure parts faster. For prototyping runs, some even keep popular ICs, resistors, and connectors in stock for instant deployment.

3. Automated SMT Assembly: The Speed Engine

Surface Mount Technology (SMT) lines dominate rapid assembly:

- Pick-and-Place Robots: High-speed machines place 30,000+ components per hour with micron-level accuracy.

- Reflow Soldering Ovens: Advanced thermal profiling ensures perfect solder joints in minutes.

- Automated Optical Inspection (AOI): AI-driven cameras instantly detect soldering defects, eliminating manual checks.

4. Through-Hole Assembly & Flexible Soldering

For boards requiring a mix of SMT and through-hole components, selective soldering robots and wave soldering systems complete the job quickly without compromising on reliability.

5. Concurrent Testing: Quality at Speed

Testing is woven into the assembly line:

- In-Circuit Testing (ICT) validates electrical performance.

- Functional Testing simulates real-world operation.

- X-Ray Inspection verifies hidden connections (e.g., BGA chips).

Real-World Example: A 24-Hour PCB Assembly Workflow

Imagine a medical device startup needs 50 prototype boards in a day. Here’s how a rapid PCB assembly service delivers:

- 8:00 AM: The customer uploads design files (Gerber, BOM) and selects assembly options.

- 9:00 AM: AI-powered DFM analysis completes; engineer confirms specs.

- 11:00 AM: Components are picked from onsite inventory.

- 1:00 PM: SMT lines populate boards; AOI validates quality.

- 4:00 PM: Manual assembly for connectors/mix-tech components.

- 6:00 PM: Functional testing under load conditions.

- 8:00 AM Next Day: Boards shipped via overnight courier.

Key Advantages of Rapid PCB Assembly

- Faster Time-to-Market: Launch products weeks ahead of competitors.

- Lower Risk: Test designs iteratively without costly delays.

- Scalability: Seamlessly shift from 10 prototypes to 10,000 units.

- Cost Control: Minimize warehousing and idle production time.

When to Choose Rapid PCB Assembly

This approach shines for:

- Prototyping (IoT devices, wearables, robotics).

- Emergency Replacements for failed components.

- Low-to-Mid Volume Production (certifications, pilot batches).

- High-Complexity Boards requiring quick validation.

Maximizing Speed: Tips for Customers

- Simplify Designs: Minimize exotic components or complex layers.

- Standardize Materials: Use common substrates (FR-4) and finishes (HASL, ENIG).

- Provide Clear Documentation: Detailed BOMs and assembly notes prevent queries.

- Leverage Turnkey Services: Let your partner handle sourcing, assembly, and testing—all under one roof.

Choosing the Right Partner for Rapid Assembly

Look for vendors with:

- Certifications: ISO 9001, IPC-A-610 Class 3.

- Transparent Tracking: Live updates via web portals.

- Scalable Capacity: Ability to handle rush jobs without bottlenecks.

- Value-Adds: Engineering support, design-for-test feedback.

Conclusion: Speed Meets Precision

A rapid PCB assembly process isn’t just about moving fast—it’s about integrating technology, expertise, and efficient workflows to produce flawless boards on-demand. As demand for smart devices and IoT solutions grows, this accelerated approach is becoming the backbone of innovation. Whether you’re iterating a prototype or scaling production, partnering with a tech-forward assembly house ensures you stay agile, competitive, and ready for what’s next.

Ready to Accelerate Your Project?

Contact a rapid PCB assembly expert today to discuss your timeline and technical needs!

Keywords for SEO: Rapid PCB assembly, Fast PCB prototyping, Quick turnkey PCB, Accelerated electronics manufacturing, High-speed SMT assembly, PCB assembly process, Fast PCB production, SMT pick-and-place, PCB testing automation.