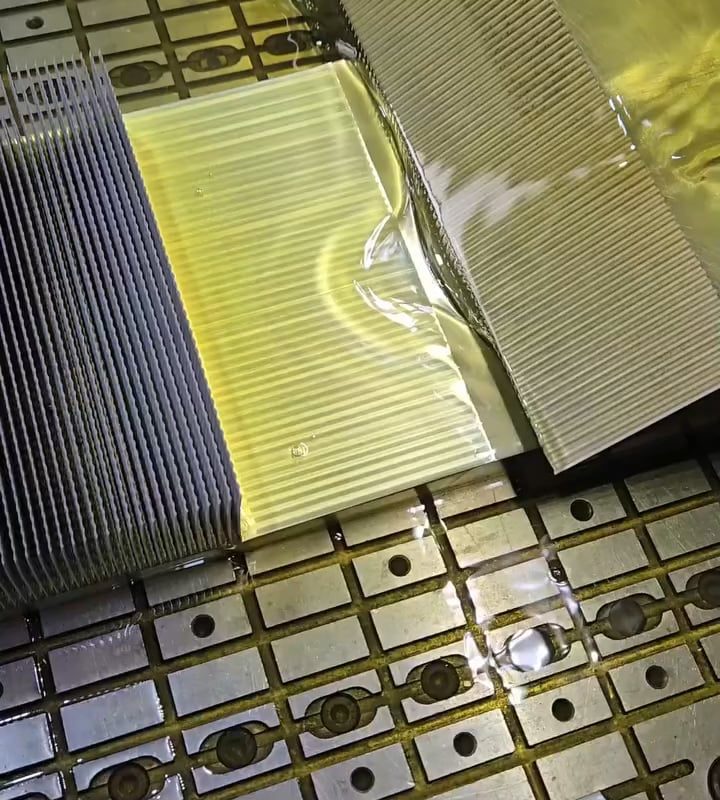

Credit: wekiko23 (IG)

The Ultimate Guide to Heatsink Manufacturing: Processes, Materials, and Innovations

Thermal management is critical for the performance and longevity of electronic devices, and heatsinks are at the heart of this process. From consumer electronics to aerospace systems, heatsinks efficiently dissipate heat away from sensitive components. In this guide, we’ll explore how heatsinks are manufactured, the materials and processes involved, and the latest trends shaping the industry.

Why Heatsink Manufacturing Matters

Heatsinks prevent overheating in devices like CPUs, GPUs, power transistors, and LED lighting systems. A poorly designed or manufactured heatsink can lead to:

- Reduced device efficiency and lifespan

- Thermal throttling (slowed performance)

- Catastrophic component failure

Choosing the right manufacturing method ensures optimal heat dissipation, durability, and cost-effectiveness for your application.

Key Materials Used in Heatsink Production

The choice of material directly impacts thermal conductivity, weight, and cost:

-

Aluminum

- Advantages: Lightweight, affordable, excellent thermal conductivity (∼200 W/mK for alloys like AA6063).

- Common Uses: Electronics, LED lighting, automotive systems.

-

Copper

- Advantages: Superior thermal conductivity (∼400 W/mK) ideal for high-performance applications.

- Drawbacks: Heavy and costly compared to aluminum.

-

Composite Materials

- Examples: Aluminum-copper hybrids, graphite composites, or ceramic-filled polymers.

- Benefits: Balance weight, cost, and conductivity for specialized needs.

Heatsink Manufacturing Processes Explained

1. Extrusion

- How It Works: Aluminum billets are heated and forced through a die to create long heatsink profiles, which are then cut to size.

- Pros: Cost-effective for high-volume production, consistent quality.

- Limitations: Design complexity is restricted by die capabilities.

2. Die Casting

- Process: Molten metal (often aluminum or zinc) is injected into a mold under high pressure.

- Applications: Complex shapes with fins and mounting features.

- Best For: High-volume orders requiring intricate geometries.

3. CNC Machining

- Method: Blocks of metal are precision-cut using computer-controlled tools.

- Advantages: Ideal for custom, low-volume prototypes or ultra-high-performance heatsinks.

- Drawbacks: Higher cost and material waste.

4. Stamping & Cold Forging

- Process: Sheet metal is stamped or forged into shape without melting.

- Benefits: Fast production, cost-efficient for simple designs like folded-fin heatsinks.

5. Additive Manufacturing (3D Printing)

- Innovation: Creates complex, topology-optimized heatsinks impossible with traditional methods.

- Materials: Copper, aluminum, and specialty alloys.

- Use Cases: Custom aerospace or medical devices.

6. Bonded Fin Technology

- Method: Fins are mechanically or thermally bonded to a base plate.

- Result: High fin density for superior cooling in compact spaces.

Custom Heatsink Manufacturing: What to Consider

When partnering with a manufacturer, specify:

- Thermal Requirements: Heat load (watts) and maximum allowable temperature rise.

- Size & Space Constraints: Dimensions, weight limits, and airflow conditions.

- Environment: Corrosive, high-vibration, or outdoor settings may require coatings (e.g., anodizing).

- Compliance: Industry certifications (e.g., RoHS, ISO 9001).

Aluminum vs. Copper Heatsinks: Which Is Better?

| Factor | Aluminum | Copper |

|---|---|---|

| Thermal Conductivity | Good (∼200 W/mK) | Excellent (∼400 W/mK) |

| Cost | Lower | 2-3x more expensive |

| Weight | Lightweight | Heavy |

| Machinability | Easier to extrude/cast | More challenging to process |

Copper is best for high-heat applications, while aluminum dominates general-purpose uses due to its balance of performance and affordability.

Design Innovations in Modern Heatsinks

- Skived Fin Design: Thin, high-density fins cut from a solid block for maximum surface area.

- Vapor Chambers: Phase-change technology for rapid heat spreading (used in premium CPUs/GPUs).

- Hybrid Liquid-Air Cooling: Combines liquid cooling plates with traditional finned heatsinks.

- Smart Heatsinks: Integrated sensors for real-time thermal monitoring.

How to Choose a Heatsink Manufacturer

Look for partners that offer:

- End-to-End Capabilities: Design, prototyping, testing, and mass production.

- Material Expertise: Knowledge of alloys, composites, and coatings.

- Quality Control: Rigorous thermal testing (e.g., CFD analysis, infrared imaging).

- Scalability: Flexibility to support prototypes to high-volume orders.

The Future of Heatsink Manufacturing

- Miniaturization: Nano-fins and microchannel designs for compact devices.

- Sustainable Materials: Recycled aluminum and biodegradable composites.

- AI-Driven Design: Generative AI to create ultra-efficient, lightweight structures.

- Integration with PCBs: Embedded heatsinks for space-constrained electronics.

Conclusion

Heatsink manufacturing has evolved from simple extruded designs to sophisticated solutions tailored for extreme thermal challenges. By understanding the materials, processes, and innovations driving the industry, you can select the right heatsink to maximize performance, reliability, and cost efficiency.

Need a custom heatsink solution? Partner with a manufacturer that leverages cutting-edge technology and decades of thermal engineering expertise to meet your unique requirements.

Optimized Keywords: Heatsink manufacturing, aluminum heatsinks, copper heatsinks, extruded heatsinks, CNC heatsink machining, custom heatsink design, thermal management solutions, heatsink materials, bonded fin heatsinks, heatsink manufacturing process.

Meta Description: Discover how heatsinks are manufactured, including materials, processes like extrusion and CNC machining, design innovations, and tips for choosing the best thermal solution for your electronics.