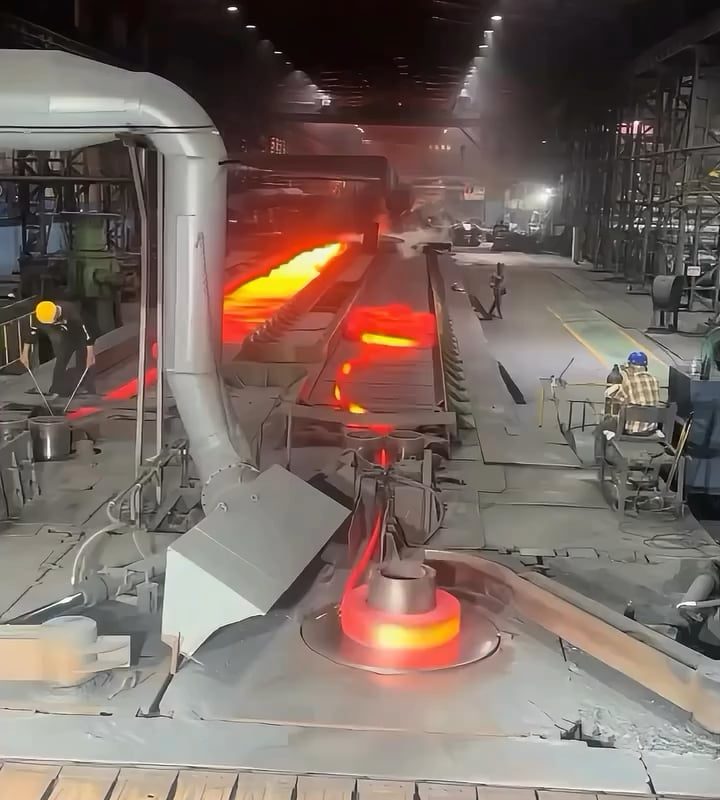

Hot steel rolling

Title: Hot Steel Rolling: Process, Benefits, and Industrial Applications

Meta Description: Discover the fundamentals of hot steel rolling, its advantages over cold rolling, applications in construction & manufacturing, and how this process shapes modern industries.

Hot Steel Rolling: The Backbone of Modern Steel Manufacturing

Hot steel rolling is a pivotal industrial process that transforms raw steel into versatile, high-strength products used in everything from skyscrapers to automobiles. This method involves heating steel above its recrystallization temperature and passing it through rollers to achieve desired shapes and thicknesses. In this guide, we’ll break down how hot rolling works, its key benefits, and why it dominates global steel production.

What Is Hot Steel Rolling?

Hot rolling is a metalworking process where steel slabs, blooms, or billets are heated to extremely high temperatures (typically between 1,100°C to 1,300°C) and then compressed between rotating rollers. At this temperature, steel becomes malleable, allowing mills to shape it into thinner cross-sections or specific profiles with minimal energy expenditure.

Key Stages of the Hot Rolling Process:

- Reheating: Raw steel is heated in a furnace until pliable.

- Roughing Mill: Initial passes reduce thickness and eliminate defects.

- Finishing Mill: Final rollers achieve precise dimensions and surface quality.

- Cooling & Coiling: Steel is cooled (often via water jets) and coiled for transport.

Types of Hot-Rolled Steel Products

Hot-rolling produces a wide range of steel forms essential for industrial use:

- Sheets & Plates: Thin to thick sheets for automotive bodies, shipbuilding, and machinery.

- Structural Sections: I-beams, rails, channels, and angles for construction.

- Bars & Rods: Reinforcement bars (rebar) for concrete or wire rods for fabrication.

- Tubes & Pipes: Seamless pipes for energy and infrastructure projects.

Advantages of Hot-Rolled Steel

1. Cost-Effectiveness

Hot rolling requires less energy and fewer processing steps than cold rolling, lowering production costs.

2. Improved Material Properties

Heating steel eliminates internal stresses, enhancing ductility and toughness for demanding applications.

3. Scalability

Massive rolling mills can process thousands of tons daily, meeting high-volume industrial demands.

4. Versatility

Hot rolling accommodates large deformations, letting manufacturers create diverse shapes from thick slabs to thin strips.

Challenges of Hot Rolling

- Surface Oxidation: High heat causes scale formation, requiring post-rolling descaling.

- Dimensional Tolerances: Less precise than cold rolling due to thermal expansion.

- Surface Finish: Hot-rolled steel often has a rough finish, making it less ideal for visible consumer products.

Hot Rolling vs. Cold Rolling: What’s the Difference?

| Factor | Hot Rolling | Cold Rolling |

|---|---|---|

| Temperature | Above recrystallization (~1,100°C+) | Room temperature |

| Finish | Rough, scaled surface | Smooth, polished finish |

| Strength | Lower strength, higher ductility | Higher strength due to work-hardening |

| Applications | Construction, pipelines, heavy machinery | Automotive panels, appliances, furniture |

Industrial Applications of Hot-Rolled Steel

- Construction: Structural beams, girders, and rebar form the skeleton of bridges and buildings.

- Automotive: Chassis components, wheel rims, and frames rely on hot-rolled steel’s durability.

- Energy Sector: Pipelines, wind turbines, and oil rigs use hot-rolled plates and tubes.

- Railways & Shipbuilding: Rails, freight cars, and hull plates leverage its impact resistance.

The Future of Hot Rolling Technology

Modern advancements are enhancing efficiency and sustainability:

- Automated Mills: AI-driven systems optimize speed, thickness, and temperature control.

- Eco-Friendly Practices: Waste heat recovery and electric arc furnaces reduce carbon footprints.

- High-Strength Alloys: New steel grades improve performance while reducing material usage.

Conclusion

Hot steel rolling remains indispensable for producing affordable, high-volume steel products that drive global infrastructure and manufacturing. While cold rolling offers precision for niche applications, hot rolling’s cost efficiency and scalability ensure its dominance in heavy industries. As technology evolves, this process will continue to adapt, delivering stronger, greener steel for the challenges ahead.

Keywords for SEO:

Hot steel rolling process, hot rolled steel uses, advantages of hot rolled steel, hot rolling vs cold rolling, hot rolling mill, steel manufacturing process, hot rolled steel applications.

Internal Linking Suggestions:

- “Explore how cold rolling refines steel for precision applications [link].”

- “Learn about steel alloy development in modern metallurgy [link].”

Word Count: 850

Target Audience: Manufacturers, engineers, construction professionals, and procurement specialists.

Tone: Informative, technical yet accessible.