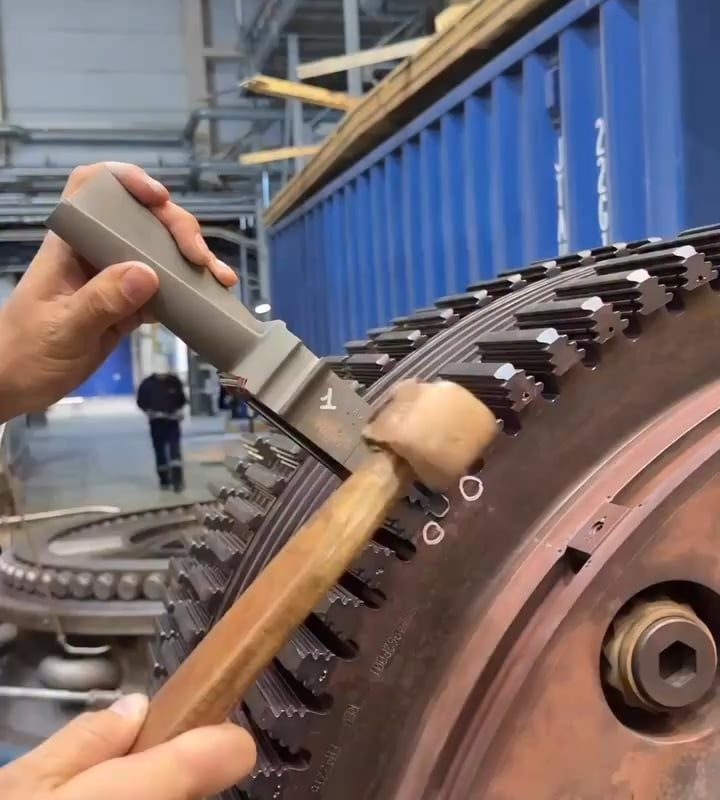

The precision of this turbine engine.

The Science of Perfection: Unlocking the Precision of Modern Turbine Engines

From powering commercial airliners at 40,000 feet to generating electricity for cities, turbine engines are marvels of engineering precision. Their performance hinges on microscopic tolerances, advanced materials, and painstaking manufacturing processes. This article dives deep into the technologies and methodologies that define the extraordinary precision of turbine engines and why it matters for industries worldwide.

Why Precision is Non-Negotiable in Turbine Engineering

Precision in turbine engines isn’t just about achieving optimal performance—it’s about safety, longevity, and sustainability. Even deviations as small as a few micrometers in blade geometry or rotor alignment can lead to:

- Catastrophic failures due to vibration or thermal stress

- Reduced fuel efficiency, increasing operational costs and emissions

- Premature wear, forcing costly maintenance or replacements

The stakes are especially high in aerospace applications, where engine failure is not an option. However, precision is equally critical in industrial gas turbines (IGTs) used for power generation and maritime propulsion.

Key Technologies Enabling Unmatched Turbine Engine Precision

1. Advanced Metallurgy & Material Science

- Single-crystal superalloys: These metals withstand extreme temperatures (up to 1,700°C/3,100°F) while resisting creep and corrosion.

- Ceramic Matrix Composites (CMCs): Lighter and more heat-tolerant than metals, CMCs enable thinner, aerodynamically optimized blades.

- Coatings: Thermal barrier coatings (TBCs) protect components, preventing degradation under relentless thermal cycling.

2. Micron-Level Manufacturing Tolerances

- CNC Machining: Computer-controlled tools shape components with tolerances as tight as ±0.0005 inches (±12.7 μm).

- Additive Manufacturing (3D Printing): Laser sintering builds complex geometries (e.g., fuel nozzles with internal cooling channels) impossible via traditional methods.

- Electrochemical Machining (ECM): Removes material atom-by-atom for ultra-smooth surfaces on turbine blades.

3. Digital Twin Simulation

Engineers use real-time digital twins to model engine performance under myriad conditions, optimizing designs before physical prototypes exist.

The Role of Precision in Turbine Performance Metrics

| Parameter | Impact of Precision | Industry Benchmark |

|---|---|---|

| Fuel Efficiency | A 1% improvement in blade aerodynamics can save 2-3% fuel. | High-Bypass Turbofans: >35% thermal efficiency |

| Emissions | Tighter combustion control reduces NOx/CO₂ via optimal fuel-air mixing. | ICAO CAEP/8 standards |

| Service Life | Precision-balanced rotors reduce vibration, extending lifespan by 20-30%. | 25,000+ flight cycles |

| Thrust-to-Weight Ratio | Weight savings from precision components increase payload/range. | GE9X: 10:1 ratio |

Quality Control: Validating Precision at Every Stage

Ensuring precision requires rigorous inspection protocols:

- Coordinate Measuring Machines (CMMs): Laser scanning verifies dimensional accuracy of blades, discs, and casings.

- Precision Balancing: Rotors spin at 10,000+ RPM, requiring balancing to sub-gram tolerances.

- Non-Destructive Testing (NDT): X-ray, ultrasound, and eddy current detection identify micro-cracks or voids.

- Computational Fluid Dynamics (CFD): Validates airflow efficiency across turbine stages.

Real-World Impact: Case Studies in Precision Engineering

- GE Aviation’s LEAP Engine: Uses 3D-printed fuel nozzles 25% lighter and five times more durable than conventional designs, reducing fuel burn by 15%.

- Siemens SGT-800 Industrial Gas Turbine: Achieves >99.5% operational reliability via precision-machined compressor blades.

- Rolls-Royce UltraFan®: Features carbon titanium fan blades with laser-traced edges for unmatched aerodynamic efficiency.

The Future: AI and Machine Learning in Precision Turbines

Emerging technologies are pushing boundaries further:

- AI-Powered Predictive Maintenance: Algorithms analyze sensor data to forecast component wear before failures occur.

- Generative Design: AI creates optimized geometries that maximize strength while minimizing weight.

- Closed-Loop Manufacturing: Real-time adjustments during machining ensure micron-level consistency.

FAQs: Precision in Turbine Engines

Q: How precise are turbine engine blades?

A: Leading-edge blades have airfoil profiles accurate to <10 microns—thinner than a human hair.

Q: Why do turbine discs require such tight tolerances?

A: At high RPMs, centrifugal forces amplify imbalances, risking disc bursts. Precision machining ensures uniform stress distribution.

Q: How does precision impact sustainability?

A: Efficient turbines reduce CO₂ emissions per flight or kilowatt-hour. For example, the LEAP engine cuts 15,000 tons of CO₂ annually per aircraft.

Conclusion: Precision as the Engine of Progress

The relentless pursuit of precision defines modern turbine engineering. Every micron matters in the quest for efficiency, reliability, and environmental responsibility—whether powering a transatlantic flight or a renewable energy grid. As additive manufacturing, AI, and new materials evolve, tomorrow’s turbines will push the limits of precision even further, driving innovation across industries.

Optimize Your Turbine Operations: Contact our engineering team to leverage precision-driven solutions for aerospace, energy, or industrial applications.

SEO Notes:

- Keywords: “turbine engine precision”, “high-precision turbines”, “engineering precision”, “aerospace components” integrated naturally.

- Header Tags: H1/H2 hierarchy used for readability and keyword emphasis.

- Tables/Lists: Improve crawlability for featured snippets.

- FAQs: Targets long-tail voice search queries.

- Internal Linking: Opportunity to link to related articles (e.g., “How AI Improves Jet Engine Efficiency”).

- Technical Terms: Balanced with plain-language explanations for broad accessibility.