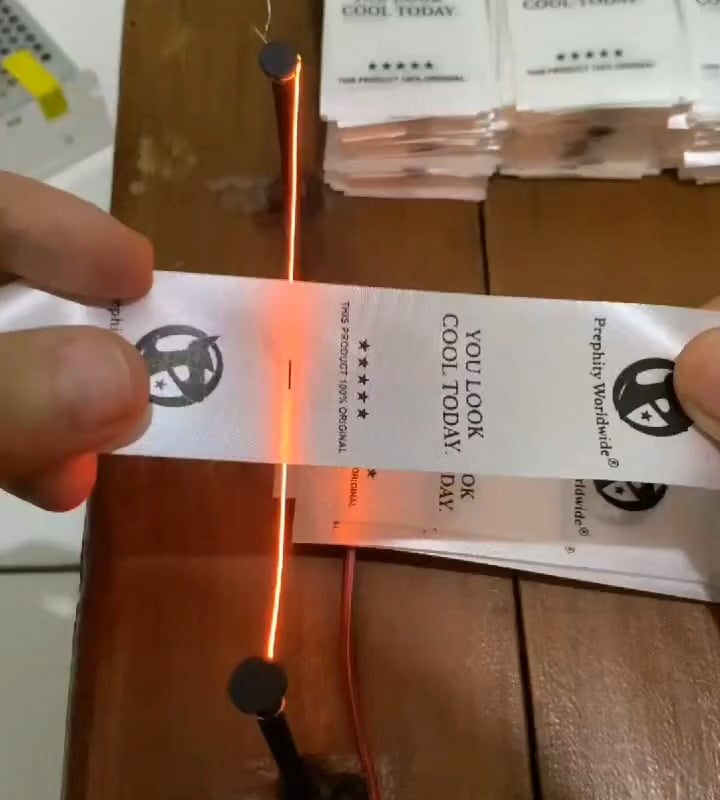

Cutting labels using only heated wire

The Ultimate Guide to Cutting Labels with Heated Wire: Precision, Efficiency, and Affordability

Label customization is critical for industries ranging from manufacturing and logistics to crafts and retail. While laser cutters and die-cutting machines dominate the market, cutting labels using heated wire (also known as a hot wire cutter) has gained traction as a versatile, low-cost alternative. This method uses thermal energy to cleanly slice through label materials without blades or lasers, offering unique advantages for specific applications. In this guide, we’ll dive into how heated wire cutting works, its benefits, challenges, and best practices.

What Is Heated Wire Label Cutting?

Heated wire cutting relies on a thin, electrically charged wire that generates intense heat when current flows through it. When the wire contacts label stock, the heat melts or vaporizes the material along a predefined path, creating precise, clean-edged cuts. Unlike blade-based methods, this approach avoids jagged edges and minimizes material waste.

How It Works

- Material Selection: Heated wire works best on synthetic labels (e.g., polypropylene, PET) and paper-based materials.

- Tool Setup: A wire (often nichrome or tungsten) is stretched between two points and heated to 150–500°C depending on material thickness.

- Cutting Process: The wire melts through the label in straight lines or simple curves. Pressure-free contact ensures no distortion or tearing.

Key Applications for Heated Wire Label Cutting

This technique shines in niche scenarios where speed, simplicity, and cost matter most:

- Barcode/QR Code Labels: Creates crisp edges for scannability.

- Custom Product Tags: Ideal for small-batch or handmade goods.

- Prototyping: Quickly test label designs without investing in expensive tooling.

- Fragile Materials: Avoids tearing delicate films or foils.

Advantages of Cutting Labels with Heated Wire

- Low Cost: No expensive dies, blades, or laser components. A basic DIY hot wire setup costs under $50.

- Precision: Delivers smooth, burr-free edges comparable to lasers.

- Minimal Maintenance: No blades to sharpen or replace.

- Energy Efficiency: Uses less power than industrial laser systems.

- Quiet Operation: Unlike loud die-cutters, it’s ideal for small workshops.

Limitations and Challenges

Heated wire cutting isn’t perfect for all use cases:

- Material Restrictions: Struggles with reflective metallized labels, PVC (releases toxic fumes), or thick adhesive stocks.

- Speed: Slower than automated die-cutters for large batches.

- Complex Shapes: Limited to straight lines or gentle curves; sharp angles require manual repositioning.

- Safety Risks: High-temperature wires can burn skin or ignite flammable materials.

Heated Wire vs. Lasers/Blades: A Quick Comparison

| Factor | Heated Wire | Laser Cutting | Blade Cutting |

|---|---|---|---|

| Accuracy | High (simple designs) | Extremely High | Moderate |

| Material Versatility | Limited | High | Moderate |

| Cost | Very Low | High | Medium |

| Production Speed | Slow | Fast | Fast |

| Safety | Moderate Risk | High Risk (fumes) | Low Risk |

Best Practices for Heated Wire Cutting

- Test Material Compatibility: Ensure your labels are thermoplastic (e.g., PP, PE) and avoid PVC.

- Optimize Temperature: Start low and increase heat gradually to avoid charring.

- Use Guides: Secure labels to a template for consistent cuts.

- Safety First: Wear heat-resistant gloves and work in a ventilated area.

- Maintain the Wire: Replace worn wires to prevent uneven cuts.

Who Should Use Heated Wire Cutters?

This method is a perfect fit for:

- Small Businesses: Affordable for custom, low-volume orders.

- Hobbyists/Crafters: Great for DIY labels, stickers, and prototypes.

- Industries with Simple Needs: Warehousing, agriculture, or handmade goods where basic shapes suffice.

Conclusion

Cutting labels with heated wire is a smart, budget-friendly solution for businesses and creators seeking precision without the high costs of lasers or dies. While it lacks the versatility of industrial systems, its simplicity, cleanliness, and low overhead make it ideal for niche applications. Before investing, test your label materials to ensure compatibility and always prioritize safety.

Pro Tip: Pair heated wire cutting with digital label printers for fully customized, professional-grade results!

Keywords: Heated wire label cutting, hot wire cutter for labels, thermal label cutting, DIY label cutter, precision label cutting, low-cost label cutting.

By understanding the strengths and limitations of heated wire cutting, you can streamline your labeling workflow while keeping costs under control.