Building a new (dead) line next to a 345,000 volt line.

Building a New Dead Line Next to a 345,000-Volt Transmission Line: Key Considerations for Safety & Success

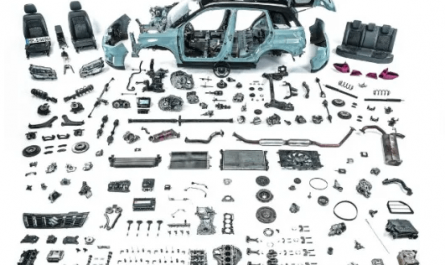

High-voltage transmission lines are the backbone of modern electrical grids. When grid operators or utilities need to expand capacity, improve redundancy, or prepare for future demand, building new transmission infrastructure becomes essential. One common scenario is installing a new dead line (de-energized line) adjacent to an existing 345kV (345,000 volt) transmission line. This requires meticulous planning, strict safety protocols, and specialized engineering expertise.

Why Build a Dead Line Next to an Existing 345kV Line?

- Grid Expansion: Adding redundant capacity ensures reliability during outages or maintenance.

- Future Proofing: Installing a de-energized line allows utilities to activate it later as demand grows, minimizing future disruptions.

- Right-of-Way Optimization: Utilizing existing transmission corridors reduces land acquisition costs and environmental impact.

- Storm Hardening: Strengthening infrastructure in disaster-prone areas by adding resilient backup lines.

Critical Planning & Engineering Steps

1. Right-of-Way Assessment & Permitting

- Survey Existing Infrastructure: Confirm the precise location, height, and configuration of the live 345kV line. Use LiDAR or drone mapping for accuracy.

- Clearance Compliance: Ensure compliance with NESC (National Electrical Safety Code) and regional standards for minimum safe distances between live and dead lines.

- Environmental Studies: Assess impacts on wildlife, vegetation, and waterways. Mitigation plans may be required.

2. Structural Engineering & Design

- Tower/Structure Selection: Choose structures compatible with the existing line’s load capacity and spacing. Options include lattice towers, monopoles, or H-frame structures.

- Foundation Design: Soil testing is critical to prevent subsidence, especially in areas prone to flooding or erosion.

- Galvanic Corrosion Prevention: Use materials that minimize electrochemical reactions between new and existing hardware.

3. Safety Considerations for Proximity Construction

- Induced Voltage Mitigation: De-energized lines near high-voltage live lines can still develop dangerous induced voltages. Grounding crews and equipment is non-negotiable.

- Minimum Approach Distances (MADs): Workers and equipment must maintain OSHA/utility-specified MADs (e.g., 21 feet for 345kV to prevent arc flash).

- PPE & Training: Crews must wear voltage-rated gloves, insulating tools, and FR clothing. Regular safety briefings are mandatory.

Construction Best Practices

-

Phased Construction:

- Phase 1 – Foundation Work: Excavate and pour foundations during dry seasons to avoid destabilization.

- Phase 2 – Erection: Use cranes or helicopters to place structures, ensuring no contact with live lines.

- Phase 3 – Conductor Stringing: Employ tension-stringing equipment to prevent sagging into the energized corridor.

-

Live-Line Coordination:

- Schedule work during periods of low electrical demand to reduce risk.

- Collaborate with the grid operator to de-energize the adjacent line temporarily if feasible (rare and costly).

-

Monitoring & QC:

- Use real-time tension monitoring during conductor installation.

- Inspect hardware connections with thermal imaging to detect hotspots post-construction.

Challenges & Mitigation Strategies

- Weather Delays: High winds or ice can halt construction. Plan for seasonal buffers and use weather-resistant conductors (e.g., ACCC).

- Community Opposition: Engage stakeholders early with clear communication about noise, visual impact, and long-term benefits.

- Supply Chain Issues: Source materials like conductors, insulators, and steel early to avoid project delays.

The Bottom Line

Building a dead transmission line next to a live 345kV line requires precision engineering, unwavering safety discipline, and proactive risk management. By partnering with experienced contractors, adhering to NESC/OSHA guidelines, and leveraging advanced technologies, utilities can execute these projects efficiently while protecting workers, communities, and the grid.

Keywords for SEO:

345kV transmission line construction, dead line installation, high-voltage safety protocols, utility infrastructure projects, transmission right-of-way planning, NESC compliance, induced voltage mitigation, electrical grid expansion, OSHA MAD standards, transmission engineering best practices

By focusing on these critical factors, your project will not only enhance grid resilience but also set a benchmark for safe and sustainable infrastructure development.