This is moving skyscraper-sized turbine blades. The wild logistics behind hauling a single wind turbine blade.

Title: Moving Skyscraper-Sized Wind Turbine Blades: The Wild Logistics Behind Hauling a Single Blade

Meta Description: Discover the jaw-dropping engineering and logistics required to transport massive wind turbine blades. Explore the challenges, innovations, and teamwork powering the renewable energy revolution.

The Wild Logistics Behind Hauling a Single Wind Turbine Blade

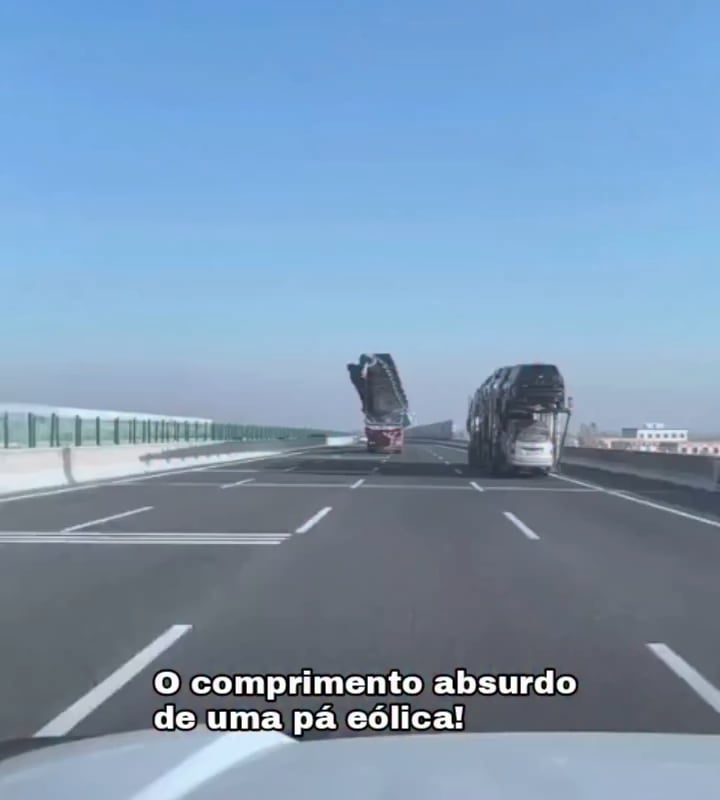

Imagine maneuvering a structure longer than a Boeing 747’s wingspan, heavier than 10 elephants, and taller than the Statue of Liberty—all while navigating twisty backroads, railroad bridges, and sleepy towns. This is the reality of transporting a single wind turbine blade, a feat of engineering and logistics that keeps the renewable energy industry spinning.

Why Are Wind Turbine Blades So Massive?

Modern wind turbines are marvels of efficiency: larger blades capture more wind energy, spinning turbines even in low-breeze conditions. Today’s blades can stretch over 350 feet long—rivaling skyscrapers—and generate enough electricity to power thousands of homes. But bigger blades mean bigger headaches for the teams tasked with moving them from factories to remote wind farms.

Transport Challenges: A Logistical Nightmare

-

Sheer Size & Weight:

A single blade can weigh 20–30 tons and extend beyond 100 meters (328 feet). Their delicate, aerodynamic design demands zero flexing or vibration during transit to avoid cracks. -

Infrastructure Struggles:

Roads weren’t built for behemoths. Teams must avoid tunnels, low-hanging power lines, narrow bridges, and sharp turns. Some routes require dismantling guardrails, trimming trees, or even temporarily removing streetlights. -

Speed & Safety:

Convoys crawl at 5–15 mph, escorted by police and pilot cars. A single trip can take days—or weeks—with drivers working only in daylight to minimize risks.

How It’s Done: The Art of Moving the Unmovable

- Specialized Transport Vehicles:

Custom trailers with hydraulic steering, dozens of wheels, and remote-controlled adjusters allow inch-perfect navigation around obstacles. Some blades are tilted vertically to dodge overpasses. - Route Engineering:

Logistics firms use LiDAR scans and drones to create 3D maps of potential routes, identifying choke points and planning detours months in advance. - Community Coordination:

Hauling a blade often requires shutting down roads and coordinating with utility companies, local governments, and residents to avoid disruptions.

The Hidden Stars: Logistical Masterminds

A single blade delivery involves a village:

- Permit Specialists: Securing hundreds of permits across multiple jurisdictions.

- Escort Teams: Piloting the convoy with precision.

- Engineers: Reinforcing roads or bridges on the fly.

Cold weather, rain, or high winds can derail plans overnight, requiring teams to pivot rapidly.

Innovations Cutting the Complexity

To slash transport woes, the industry is evolving:

- Modular Blade Designs: Segmented blades that bolt together on-site.

- On-Side Manufacturing: Mobile factories near wind farms to avoid long-haul trips.

- Smarter Routes: AI-powered software predicts traffic, weather, and infrastructure constraints in real time.

The Bigger Picture: Why It Matters

Despite the challenges, moving these giants is critical for a sustainable future. A single modern turbine offsets ~5,000 tons of CO2 annually—equivalent to planting 7,000 trees. As blades grow larger and wind farms multiply, logistics innovations will drive down costs and accelerate our shift to green energy.

FAQs: Moving Wind Turbine Blades

Q: Why do turbine blades keep getting bigger?

A: Longer blades capture more wind energy, boosting efficiency and making projects viable in lower-wind regions.

Q: How long does it take to transport one blade?

A: It varies! A 100-mile trip might take 3–7 days due to slow speeds, road modifications, and approvals.

Q: What’s the cost of transporting a single blade?

A: Estimates range from $10,000–$100,000+ per blade, depending on distance and route complexity.

Q: Are there environmental trade-offs?

A: While transport emits CO₂, turbines offset this within months. Innovations like electric transport trucks are emerging.

Q: Who handles these high-stakes moves?

A: Specialized logistics firms like Mammoet, Goldhofer, and Bennett Motor Express dominate this niche.

Final Thought

The next time you see a wind turbine spinning lazily on the horizon, remember the adrenaline-fueled journey its blades endured. From factory to field, moving these giants is a testament to human ingenuity—and a crucial piece of our clean energy puzzle.

Looking to dig deeper? Explore our articles on [The Future of Wind Energy] or [How Turbines Work] for more renewable energy insights!

Keywords for SEO:

wind turbine blade transport, wind energy logistics, hauling turbine blades, renewable energy infrastructure, wind farm construction, oversized load shipping, wind turbine engineering