Test Pilots Purposefully Stall a Boeing 717 (also known as an DC-9) during Stall/Spin Recovery Testing

Title: Inside the High-Stakes World of Aviation: Test Pilots Purposely Stall a Boeing 717 (DC-9) in Stall/Spin Testing

Introduction

In the high-stakes realm of aviation safety, few tests are as daring—or as critical—as deliberately stalling an aircraft to study its recovery capabilities. Recently, test pilots made headlines by intentionally stalling a Boeing 717 (often affectionately called the DC-9-95 due to its lineage) during stall/spin recovery testing. This controlled chaos isn’t reckless thrill-seeking—it’s a meticulously planned scientific endeavor to ensure passenger safety. Here’s what happens when pilots push an aircraft to its aerodynamic limits and why it matters to everyday air travel.

The Role of Test Pilots in Aviation Safety

Test pilots are the unsung heroes of aviation, tasked with pushing aircraft beyond normal operational boundaries to uncover vulnerabilities. Their work validates aerodynamic models, refines flight manuals, and ensures planes can recover from worst-case scenarios like stalls (loss of lift) and spins (a dangerous corkscrew descent). For the Boeing 717—a modern twin-engine jet derived from the iconic McDonnell Douglas DC-9—these tests are critical to certifying upgrades, new avionics, or improved flight control systems.

What Is Stall/Spin Testing?

- Stall: Occurs when an aircraft’s angle of attack becomes too steep, causing airflow to separate from the wings and a sudden loss of lift.

- Spin: A stall that becomes asymmetrical, sending the aircraft into a spiraling plunge.

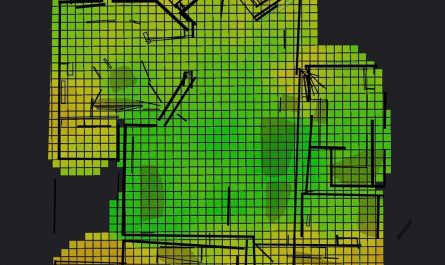

Recovery requires precise control inputs, and testing confirms the aircraft’s ability to respond predictably. Engineers embed sensors throughout the airframe to capture data on airflow, control surface effectiveness, and pilot response.

Why Purposefully Stall a Boeing 717?

The Boeing 717, a descendant of the DC-9, is known for its reliability in regional aviation. However, as technology evolves, so do safety protocols. By stalling the aircraft in controlled conditions, engineers and pilots can:

- Validate Recovery Procedures: Ensure the steps in flight manuals (e.g., reducing angle of attack, applying rudder) effectively halt spins.

- Improve Aerodynamic Modeling: Refine computer simulations used in aircraft design.

- Assess New Systems: Test how modern fly-by-wire enhancements or software updates handle extreme scenarios.

- Train Future Pilots: Data informs simulator training, preparing pilots for rare real-world emergencies.

How Stall/Spin Tests Are Conducted

-

Preparations:

- The aircraft is modified with safety parachutes (spin-recovery parachutes) to arrest uncontrollable spins.

- Test pilots ascend to a high altitude (often 15,000+ feet), ensuring ample recovery space.

- Onboard sensors record thousands of data points per second.

-

The Test Itself:

- Pilots slow the aircraft and purposely increase the angle of attack until the wings stall.

- If a spin develops, they execute recovery protocols—first neutralizing controls, then applying opposite rudder and lowering the nose.

-

Risk Mitigation:

- Tests occur over unpopulated areas, with chase planes observing.

- Parachute systems can be deployed if manual recovery fails.

The Boeing 717/DC-9: A Legacy of Robust Design

Originally designed in the 1960s, the DC-9 (and its successor, the 717) is famed for its rugged simplicity and forgiving flight characteristics. Its T-tail configuration and rear-mounted engines contribute to stable stall behavior, but real-world testing is irreplaceable. Modern updates, such as advanced stall warning systems, make these tests essential even for older airframes.

Why This Matters to Passengers and Airlines

- Safer Skies: Every successful recovery test translates to better emergency procedures, minimizing risks for passengers.

- Regulatory Compliance: Aviation authorities like the FAA and EASA require such tests for aircraft certifications.

- Longevity of Aircraft: Proven safety extends the service life of trusted workhorses like the 717/DC-9.

FAQs: Stall/Spin Testing with the Boeing 717

Q: Is stalling an aircraft dangerous during testing?

A: While inherently risky, tests are conducted at safe altitudes with multiple redundancies (e.g., recovery parachutes, chase planes).

Q: How do pilots train for stalls without a real plane?

A: Simulators replicate stall/spin physics, but real-world tests provide irreplaceable data.

Q: What’s the difference between a Boeing 717 and a DC-9?

A: The 717 (originally MD-95) is a modernized DC-9 variant with improved engines, avionics, and efficiency, but shares its aerodynamic DNA.

Q: Have any Boeing 717 stall tests led to design changes?

A: While specifics are often proprietary, data from such tests frequently informs flight manual updates and system refinements.

Conclusion

The image of a Boeing 717 intentionally plummeting toward Earth is counterintuitive—but it’s a testament to aviation’s relentless pursuit of safety. By conquering stalls and spins in controlled environments, test pilots ensure that when unforeseen emergencies occur, pilots have the knowledge and tools to bring everyone home safely. For the DC-9 lineage, these trials reinforce a legacy of resilience that keeps these aircraft flying reliably decades after their debut.

Keywords: Boeing 717 stall test, DC-9 spin recovery, aircraft stall testing, aviation safety, test pilots, angle of attack, spin recovery parachute, aerodynamic testing, FAA certification, aviation emergencies.