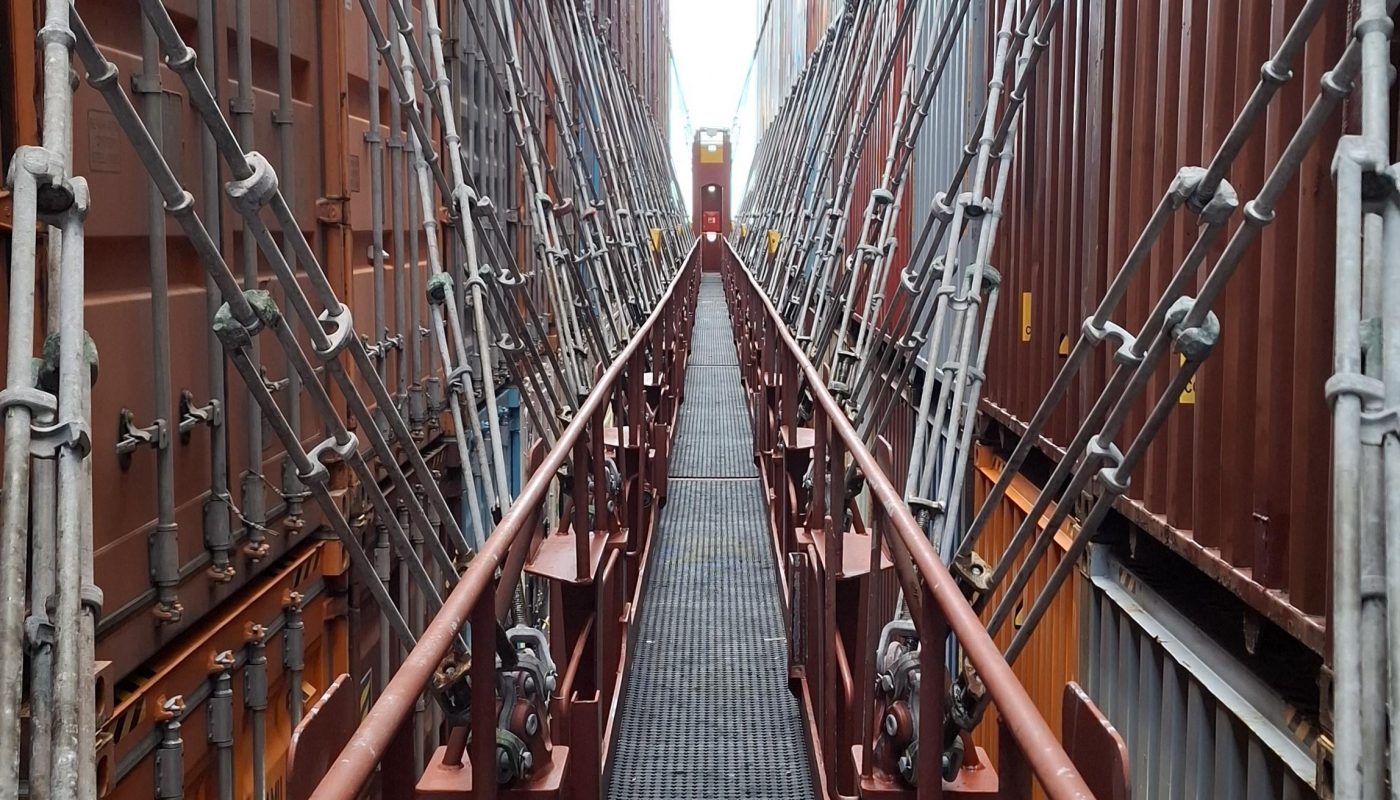

Lashing System Containers

Meta Title: The Ultimate Guide to Container Lashing Systems: Types, Benefits & Best Practices

Meta Description: Discover everything you need to know about container lashing systems, including types, benefits, safety standards, and best practices for securing cargo during maritime, road, and rail transport.

The Ultimate Guide to Container Lashing Systems: Securing Cargo Globally

What Is a Container Lashing System?

A container lashing system refers to the equipment and techniques used to secure shipping containers to transport vessels (ships, trucks, trains) or storage platforms. By preventing containers from shifting, tipping, or collapsing, lashing systems ensure cargo safety, protect infrastructure, and comply with international transport regulations.

Why Lashing Systems Matter

- Prevent Cargo Damage: Unsecured containers lead to $50M+ in global cargo damage annually (World Shipping Council).

- Avoid Accidents: Ineffective lashing causes container stacks to collapse, risking human lives and environmental disasters.

- Regulatory Compliance: Adherence to ISO 3874, SOLAS, and CSC guidelines is mandatory for international shipping.

Types of Container Lashing Systems

1. Maritime Lashing (Ship-to-Shore)

- Components: Twist locks, lashing rods, turnbuckles, and stackers.

- Application: Secures containers stacked on cargo ships exposed to rolling waves and high winds.

- Innovations: Automated tension monitoring systems for real-time adjustments.

2. Road/Rail Lashing

- Components: Chains, straps, load binders, and corner castings.

- Application: Stabilizes containers on trucks or trains maneuvering sharp turns and uneven terrain.

3. Intermodal & Storage Lashing

- Components: Crossbars, bridge fittings, and container bolts.

- Application: Used in ports, warehouses, and intermodal yards to immobilize stored containers.

Key Lashing Equipment Explained

| Component | Function | Material Used |

|---|---|---|

| Twist Locks | Locks containers vertically/horizontally | Steel alloys |

| Lashing Rods | Connects containers to deck lashing points | High-tensile steel |

| Turnbuckles | Provides tension adjustment | Galvanized steel |

| D-Shackles | Links rods to ship bays | Stainless steel |

Benefits of Professional Lashing Systems

- Enhanced Safety: Reduces workplace injuries and cargo loss by 80%.

- Regulatory Compliance: Meets IMO/ISO standards to avoid fines or shipment delays.

- Cost Efficiency: Minimizes insurance claims due to damaged goods.

5 Best Practices for Effective Container Lashing

- Pre-Trip Inspection: Check rods, turnbuckles, and twist locks for corrosion or wear.

- Weight Distribution: Never exceed container stack weight limits (e.g., 192,000 lbs for 40ft containers).

- Weatherproofing: Use galvanized or stainless-steel components in corrosive marine environments.

- Tension Control: Ensure turnbuckles are tightened uniformly—no slack but avoid over-tightening.

- Training: Certify staff in standards like ICHCA’s Lashing and Securing Code.

FAQs: Container Lashing Systems

Q: How often should lashing equipment be inspected?

A: Before every voyage and after extreme weather events. Replace damaged parts immediately.

Q: Can lashing systems be reused?

A: Yes, if undamaged. High-quality steel systems last 5–10 years with proper maintenance.

Q: What happens if lashing fails during transit?

A: Consequences include container loss overboard, cargo damage, vessel instability, and legal penalties.

Future Trends in Lashing Technology

- Smart Sensors: IoT-enabled tension monitors sending alerts via cloud platforms.

- Automated Lashing Robots: Ports like Rotterdam use AI to reduce manual labor and human error.

- Eco-Friendly Materials: Recycled steel alloys reducing the carbon footprint of lashing production.

Partner with Lashing Experts

Choosing the right container lashing system requires expertise in cargo dynamics, material science, and global regulations. Work with certified suppliers who offer:

- Customized lashing plans for oversized/heavy cargo.

- Compliance documentation (ISO 3874/2021).

- Training and 24/7 technical support.

Protect your cargo—and your reputation—with precision-engineered lashing solutions.

Optimized Keywords: container lashing system, cargo securing equipment, twist locks, lashing rods, SOLAS compliance, maritime safety, intermodal transport, container stacking, ISO 3874 standards.

Call to Action: Need a certified container lashing supplier? Contact us for a free consultation and quote today!

This SEO-optimized article targets logistics managers, freight forwarders, and shipping companies seeking actionable insights into container lashing. It combines keyword density with practical guidance to rank for commercial and informational search intent.