“Engineering So Precise Your Eyes Can’t See the Cut

Title: Engineering So Precise Your Eyes Can’t See the Cut: The Invisible Marvels of Micro-Scale Manufacturing

Meta Description: Discover how ultra-precise cutting technologies revolutionize industries from semiconductors to medicine. Learn why microscopic accuracy matters in our modern world.

Introduction: The Unseen Frontier of Precision

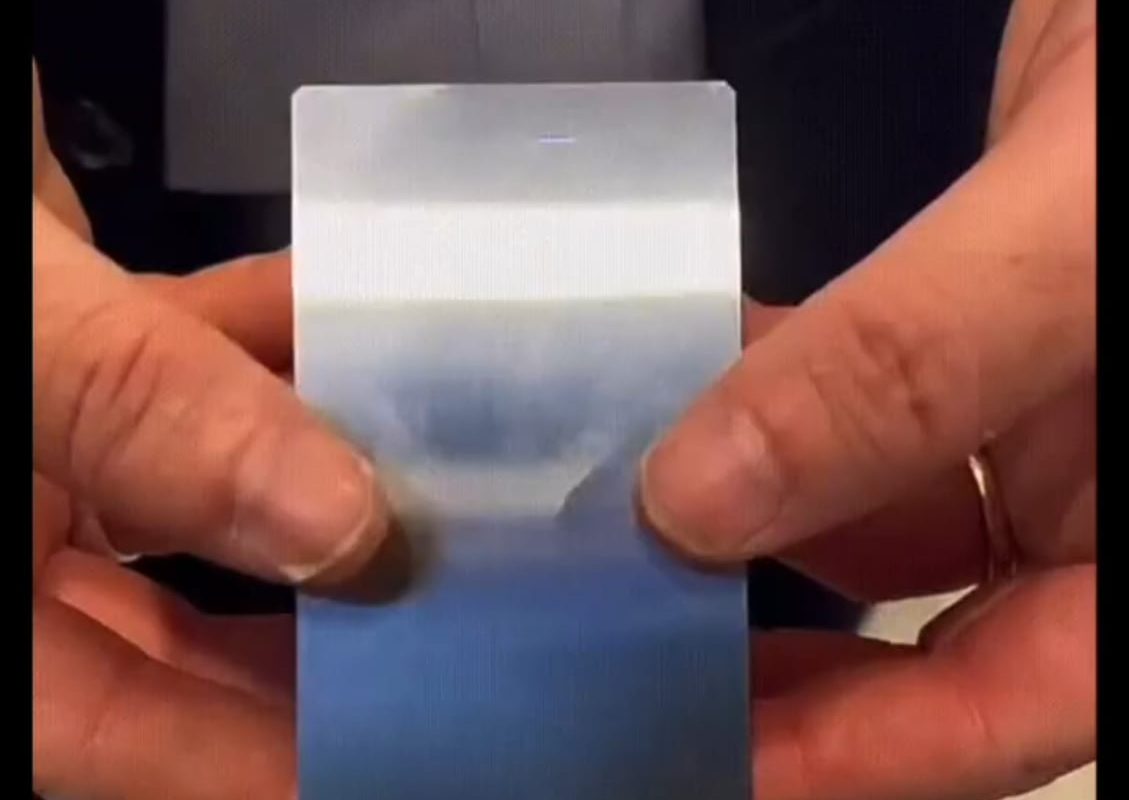

Imagine a cut so fine it’s invisible to the naked eye—thinner than a human hair, smaller than a grain of pollen. This isn’t science fiction; it’s the reality of modern precision engineering. Today, industries like aerospace, medical devices, and electronics rely on manufacturing processes so accurate that the smallest imperfection could mean the difference between success and failure. Welcome to the world of engineering where the cuts are not just precise—they’re imperceptible.

The Science of Microscopic Precision

How Small Is “Invisible”?

The human eye can typically resolve objects down to about 100 microns (0.1 millimeters). Modern engineering, however, operates at scales far smaller:

- Nanometer-level cutting (1 nanometer = 0.000001 mm) for semiconductor chips.

- Micron-level tolerances (1-5 microns) in medical stent manufacturing.

- Sub-micron surface finishes for optical lenses and mirrors.

These measurements aren’t just numbers—they represent feats of engineering that enable everything from smartphones to life-saving implants.

Tools of the Trade: From Lasers to Ion Beams

How do engineers achieve such accuracy?

-

Femtosecond Lasers:

Pulses lasting quadrillionths of a second vaporize material without heat damage, perfect for eye surgery tools and microelectronics. -

Focused Ion Beam (FIB) Machining:

Uses charged particles to “etch” materials atom by atom, critical for semiconductor defect repair. -

Diamond Turning:

Ultra-hard diamond tools shape metals and polymers with surface roughness below 10 nanometers. -

Waterjet Cutting with Abrasives:

Fine garnet particles in high-pressure water streams cut delicate materials like graphene without thermal distortion.

Why Precision Matters: Industries Revolutionized by Invisible Cuts

1. Semiconductors & Electronics

- Apple’s M-series chips contain over 15 billion transistors, each requiring atomic-scale accuracy.

- Imperfections smaller than a virus (≈20nm) can render a microchip useless.

2. Medical Devices

- Coronary stents are laser-cut from titanium tubes with tolerances tighter than 5 microns—roughly 1/10th the width of a hair.

- Surgical blades sharpened to angstrom-level edges reduce tissue trauma and scarring.

3. Aerospace & Defense

- Turbine blades in jet engines feature cooling holes drilled by lasers to 0.1mm diameters. A 10-micron error could cause catastrophic failure.

- Gyroscopes in missiles require mirrors polished to λ/20 surface accuracy (less than 30nm deviation).

4. Consumer Tech

- Smartphone OLED screens use laser-cut sapphire cover glass with edges smoother than 0.5 microns to prevent cracks.

- Watch gears are wire-cut via EDM (Electrical Discharge Machining) with backlash measured in arcseconds.

The Future: Pushing the Limits of the Invisible

Quantum Computing & Beyond

As quantum chips require qubits spaced at atomic distances (≈0.5nm), engineers are pioneering cryogenic etching and helium ion-beam lithography to manipulate single atoms.

Bio-Integration

- Neural interfaces like Neuralink demand electrodes thinner than neurons (2–4 microns) to avoid brain tissue damage.

- Lab-on-a-chip devices use microfluidic channels cut at 500nm widths to analyze DNA strands.

Sustainability Wins

- Precision reduces material waste: Cutting a silicon wafer with 99.9% accuracy saves tons of raw material annually.

- Longer-lasting products (e.g., nanoscale-coated engine parts) minimize resource consumption.

Conclusion: The Unseen Engine of Progress

Invisible precision isn’t just a technical achievement—it’s the backbone of innovation. From extending human life to connecting the globe, these imperceptible cuts enable technologies that shape our future. As engineering pushes into picometer scales (trillionths of a meter), one thing is clear: The most transformative advances are those we can’t even see.

FAQ: Engineering’s Invisible Cuts

Q: How do you measure cuts smaller than light’s wavelength?

A: Tools like scanning electron microscopes (SEMs) and atomic force microscopes (AFMs) image surfaces at sub-nanometer resolutions.

Q: Can humans manually achieve this precision?

A: No—AI-controlled systems compensate for thermal drift, vibrations, and even air molecules.

Q: What’s the ROI for such extreme precision?

A: Samsung reported a 20% yield increase in chip production after improving cutting precision by 2 nanometers.

Q: Which material is hardest to cut precisely?

A: Diamond—used in quantum sensors—requires ion beam or laser ablation to avoid fractures.

Keywords for SEO:

Microscopic precision engineering, laser cutting nanotechnology, ultra-precise manufacturing, nanometer-scale accuracy, semiconductor fabrication, medical device machining, advanced cutting technologies.

By blending innovation with microscopic accuracy, engineers continue to turn the once-impossible into the everyday—proving that the smallest cuts often make the biggest impact.