Machine component

Title: Understanding Machine Components: The Essential Building Blocks of Machinery

Meta Description: Explore the world of machine components, their types, functions, and importance in mechanical systems. Learn how they impact efficiency and reliability in industries.

Introduction

Machinery powers industries, manufacturing, and everyday technology, but its efficiency relies on the seamless interaction of its smallest parts: machine components. These fundamental building blocks ensure machines perform tasks accurately, durably, and safely. In this guide, we’ll break down what machine components are, their critical roles, common types, maintenance tips, and how selecting the right parts optimizes performance.

What Are Machine Components?

Machine components are individual parts that make up a larger mechanical system. They can be as simple as screws or as complex as gear assemblies, each designed to fulfill specific functions like transferring motion, supporting loads, or converting energy. Without these components, machines would cease to function.

Why Do They Matter?

- Functionality: Components enable core operations (e.g., gears transmit torque).

- Durability: High-quality parts extend machinery lifespan.

- Safety: Properly maintained components prevent malfunctions and accidents.

- Efficiency: Precision parts reduce energy waste and operational costs.

Core Types of Machine Components

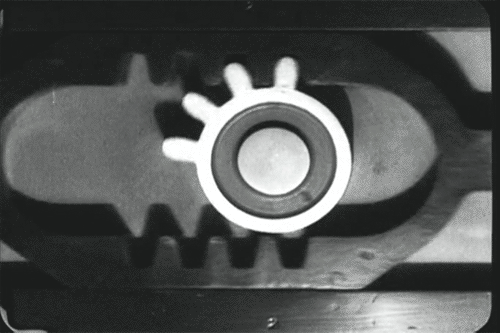

1. Bearings

Bearings reduce friction between moving parts, ensuring smooth rotation.

- Types: Ball bearings, roller bearings, sleeve bearings.

- Applications: Motors, turbines, wheels.

- Failure Risk: Overheating due to poor lubrication or misalignment.

2. Gears

Gears transmit motion and torque by interlocking teeth.

- Types: Spur gears (parallel axes), helical gears (angled teeth), bevel gears (angled axes).

- Applications: Gearboxes, clocks, automotive transmissions.

- Failure Risk: Wear from friction or improper meshing.

3. Shafts

Shafts are rotating rods that transfer power from a motor to other components.

- Types: Solid shafts, hollow shafts, flexible shafts.

- Applications: Drivetrains, pumps, conveyors.

- Failure Risk: Fatigue cracking or bending under heavy loads.

4. Fasteners

Fasteners hold components together mechanically.

- Types: Bolts, screws, nuts, washers, rivets.

- Applications: Assembly of machinery, automotive frames.

- Failure Risk: Loosening due to vibration or corrosion.

5. Couplings

Couplings connect two shafts to transmit power while accommodating misalignment.

- Types: Rigid, flexible, fluid couplings.

- Applications: Pumps, compressors, industrial machinery.

- Failure Risk: Misalignment leading to vibration or breakage.

Key Functions of Machine Components

- Power Transmission: Convert and transfer energy (e.g., belts, chains).

- Motion Control: Guide or restrict movement (e.g., slides, cams).

- Load Management: Support structural weight (e.g., frames, housings).

- Sealing & Protection: Prevent contamination (e.g., seals, gaskets).

- Energy Conversion: Transform energy types (e.g., pistons in engines).

Selecting the Right Machine Components

Choosing components requires careful consideration of:

- Material: Steel (strength), aluminum (lightweight), polymers (corrosion-resistant).

- Load Capacity: Match components to operational stress (e.g., dynamic vs. static loads).

- Environment: Temperature, moisture, and chemicals influence material choice.

- Precision: Tight tolerances ensure compatibility and reduce wear.

- Cost vs. Lifespan: Balance affordability with long-term reliability.

Pro Tip: Follow OEM (Original Equipment Manufacturer) guidelines to avoid compatibility issues.

Maintenance Best Practices

Prevent downtime and extend machine life with:

- Lubrication: Regularly grease bearings and gears.

- Alignment Checks: Ensure shafts and couplings are properly aligned.

- Inspection: Look for cracks, corrosion, or unusual noises.

- Replacement: Swap worn parts before they cause system-wide failures.

Common Failure Signs:

- Excessive noise or vibration.

- Overheating.

- Reduced efficiency (e.g., slipping belts).

The Future of Machine Components

Advancements in materials and technology are reshaping components:

- Smart Sensors: Monitor wear and performance in real time.

- 3D Printing: Enable rapid prototyping of custom parts.

- Composite Materials: Lighter, stronger alternatives to metals.

- Sustainability: Recyclable materials and energy-efficient designs.

Conclusion

Machine components are the unsung heroes behind industrial productivity and innovation. Understanding their roles, types, and maintenance needs ensures machinery operates safely, efficiently, and cost-effectively. Whether you’re an engineer, technician, or enthusiast, prioritizing high-quality components and proactive care will maximize the ROI of any mechanical system.

Ready to optimize your machinery? Consult with component experts to tailor solutions for your needs.

Keywords: Machine component, types of machine components, bearings, gears, shafts, mechanical parts, industrial machinery, component maintenance, power transmission.

Internal Links (Suggestions):

- [How to Choose Industrial Bearings: A Complete Guide]

- [Gear Failure Analysis: Causes and Prevention]

- [Sustainability in Machine Design: Trends & Tips]

By covering essential aspects of machine components and embedding SEO keywords naturally, this article aims to rank highly while delivering actionable insights for readers.