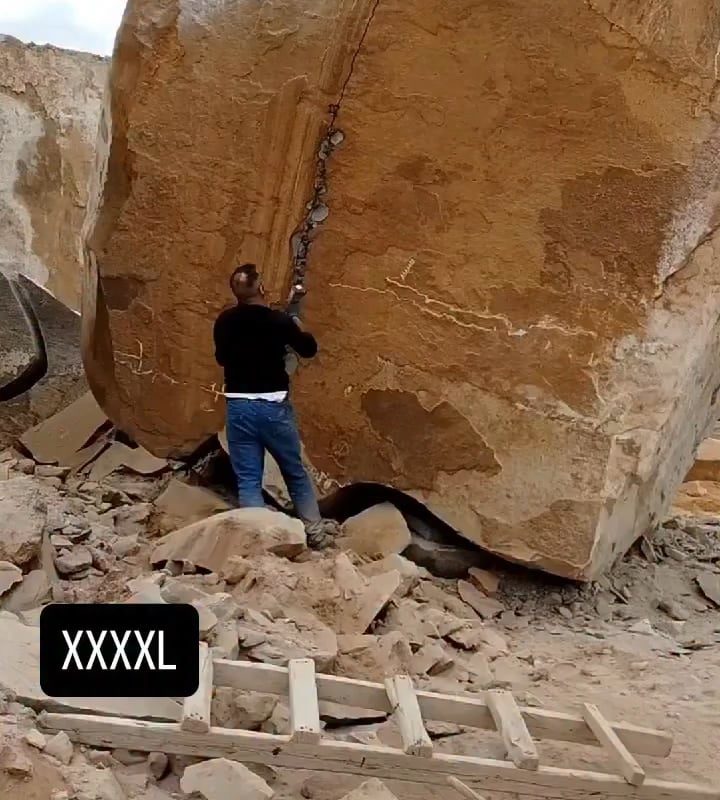

Breaking of giant rock

Breaking of Giant Rock: Techniques, Tools, and Safety Tips for Effective Rock Removal

From construction sites to landscaping projects, the task of breaking a giant rock is often a critical step in land development. Whether it’s clearing paths for infrastructure, excavating building foundations, or creating aesthetic landscapes, removing massive boulders requires specialized techniques and equipment. This article explores the most effective methods for breaking giant rocks, essential safety protocols, and modern tools that make the process efficient and environmentally responsible.

Why Break Giant Rocks?

Giant rocks can hinder progress in construction, mining, agriculture, and landscaping. Common reasons for rock removal include:

- Land Preparation: Clearing boulders for roads, buildings, or pipelines.

- Safety Hazards: Eliminating unstable rocks that threaten workers or structures.

- Resource Extraction: Accessing valuable minerals or aggregates.

- Aesthetic Landscaping: Reshaping natural stone for gardens, ponds, or water features.

Top Techniques for Breaking Giant Rocks

1. Drilling and Blasting

- Process: Holes are drilled into the rock, filled with explosives, and detonated to fracture it.

- Best For: Large-scale projects like mining or quarrying.

- Pros: Fast and effective for hard, dense rocks.

- Cons: Requires permits, safety clearances, and skilled professionals.

2. Hydraulic Rock Splitting

- Process: A hydraulic splitter expands inside pre-drilled holes, generating pressure to crack the rock.

- Best For: Precision splitting in urban areas where blasting isn’t feasible.

- Pros: Minimal noise, vibrations, and debris.

- Cons: Slower than blasting for extremely large rocks.

3. Mechanical Breaking (Rock Hammers & Excavators)

- Process: Hydraulic breakers (jackhammers) or excavator-mounted hammers pulverize the rock.

- Best For: Smaller projects or sites with strict environmental regulations.

- Pros: No explosives needed; versatile equipment.

- Cons: Limited to surface-level breaking; less efficient for deep fractures.

4. Thermal Techniques (Thermal Lance or Water Jets)

- Process: Extreme heat (from a thermal lance) or high-pressure water jets fracture the rock.

- Best For: Granite, basalt, or other heat-resistant rocks.

- Pros: High precision with minimal collateral damage.

- Cons: Energy-intensive and costly.

5. Chemical Rock Breaking Agents

- Process: Non-explosive chemicals like Dexpan® expand in drilled holes, cracking the rock over 24–48 hours.

- Best For: Sensitive environments (e.g., near historical sites).

- Pros: Silent, vibration-free, and safe for untrained operators.

- Cons: Slow; requires planning ahead.

Essential Tools & Equipment

- Hydraulic Breakers (Jackhammers): Ideal for surface-level rock fragmentation.

- Drilling Rigs: Create holes for blasting, splitters, or chemical agents.

- Hydraulic Splitters: Generate up to 5,000 tons of force for controlled splitting.

- Excavators with Hammer Attachments: Combine mobility and power for large rocks.

- Protective Gear: Helmets, goggles, ear protection, and steel-toe boots.

Safety Best Practices

Breaking giant rocks poses risks like flying debris, equipment malfunctions, and dust inhalation. Follow these guidelines:

- Survey the Site: Identify unstable terrain, underground utilities, or nearby structures.

- Use PPE (Personal Protective Equipment): Mandatory for all workers.

- Train Operators: Ensure familiarity with tools and emergency protocols.

- Control Dust & Debris: Use water sprays or barriers to minimize airborne particles.

- Adhere to Regulations: Obtain permits for blasting and disposal.

Environmental Considerations

- Noise Pollution: Opt for hydraulic splitters or chemical agents in residential zones.

- Dust Management: Apply water mist to reduce silica dust, a respiratory hazard.

- Waste Disposal: Recycle broken rock as gravel, fill material, or landscaping stones.

- Ecosystem Protection: Avoid disrupting wildlife habitats during rock removal.

FAQs About Giant Rock Breaking

Q: How much does it cost to break a giant rock?

A: Costs vary based on size, method, and location. Blasting can exceed $5,000+, while hydraulic splitting averages $1,500–$3,000.

Q: Can I break a rock without heavy machinery?

A: For small rocks (under 2 feet), manual tools like sledgehammers or feathers and wedges may work. Large rocks require professional equipment.

Q: How long does chemical rock breaking take?

A: Non-explosive agents like Dexpan® take 24–48 hours to fracture rock.

Conclusion

Breaking giant rocks demands expertise, the right tools, and careful planning. Whether using high-speed blasting for mountain excavation or silent chemical agents near urban spaces, prioritize safety, efficiency, and environmental responsibility. Partner with licensed contractors to assess your project’s needs and choose the best method for fracturing that monumental obstacle.

Got a giant rock standing in your way? Consult a rock removal specialist today for a customized solution!