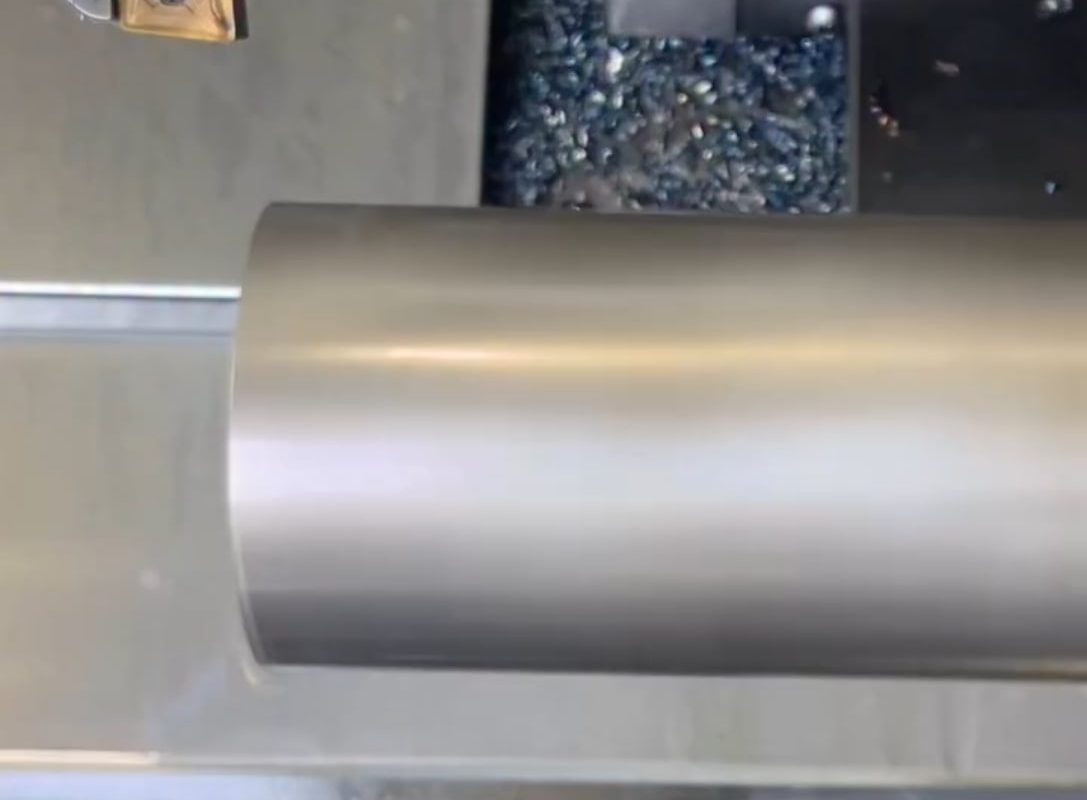

A CNC lathe machine doing it’s job

Unveiling Precision: The Intricate Dance of a CNC Lathe Machine at Work

In the heart of modern manufacturing, where precision meets efficiency, CNC lathe machines stand as tireless workhorses shaping raw materials into engineering marvels. Watching a CNC lathe machine in action is witnessing the seamless fusion of digital intelligence with mechanical power—a symphony of cutting-edge technology transforming a simple metal cylinder into a complex, high-tolerance component. Let’s explore the fascinating process of a CNC lathe “doing its job” and understand why it’s indispensable in today’s industrial landscape.

What Is a CNC Lathe Machine?

A CNC (Computer Numerical Control) lathe is a computer-controlled machining tool that rotates a workpiece on a spindle while precisely guiding cutting tools to remove material. Unlike manual lathes, CNC lathes execute programmed instructions with ultra-high accuracy, enabling the mass production of symmetrical parts like shafts, bolts, and flanges with flawless consistency.

The CNC Lathe in Action: A Ballet of Precision

Imagine a gleaming metal rod clamped securely in the lathe’s chuck. As the machine hums to life, here’s how the magic unfolds:

1. Digital Blueprint to Reality

- Every job begins with a CAD (Computer-Aided Design) model, which CAM (Computer-Aided Manufacturing) software translates into G-code—a language the CNC lathe understands.

- The machine operator loads this program, setting parameters like spindle speed, feed rate, and tool paths.

2. The Spindle Awakens

- The chuck grips the workpiece (e.g., steel, aluminum, or plastic) and rotates it at high speeds—often thousands of RPM.

- The spindle motor ensures consistent torque, vital for smooth material removal.

3. Tools Spring into Action

- A turret holding multiple cutting tools (e.g., drills, boring bars, inserts) positions itself automatically.

- As the workpiece spins, tools approach it with surgical precision, shaving off layers of material to create contours, threads, grooves, or tapers.

4. Coolant & Chips Fly

- Coolant floods the work area to reduce heat, prevent tool wear, and flush away metal chips.

- A transparent safety guard contains debris while allowing operators to monitor progress.

5. Micron-Level Accuracy

- Sensors and encoders continuously measure dimensions, making micro-adjustments to ensure tolerances within 0.001 inches (0.025 mm) are maintained.

6. Unattended Operation

- Once programmed, CNC lathes can run 24/7 with minimal supervision, producing hundreds of identical parts—perfect for high-volume manufacturing.

Key Components Making It Possible

- Control Unit: The brain (e.g., Fanuc, Siemens) executing G-code commands.

- Headstock: Houses the spindle motor and chuck.

- Turret: Holds and switches tools automatically.

- Tailstock: Supports long workpieces for stability.

- Bed: A rigid frame dampening vibrations.

- Cutting Tools: Carbide or diamond-tipped for durability.

Applications: Where CNC Lathes Shine

From everyday items to aerospace wonders, CNC lathes craft parts for:

- Automotive: Engine valves, pistons, brake rotors.

- Aerospace: Turbine shafts, landing gear components.

- Medical: Implants, surgical instruments.

- Energy: Valve bodies, pump shafts.

Why CNC Lathes Dominate Manufacturing

- Unmatched Precision: Repeatable accuracy critical for high-stakes industries.

- Speed: Faster than manual machining; reduces lead times.

- Flexibility: Quick reprogramming allows switching between part designs.

- Labor Efficiency: One operator can manage multiple machines.

- Material Versatility: Works with metals, plastics, wood, and composites.

- Cost-Effective: Lowers waste and rework costs through automation.

Conclusion: The Silent Innovator in Modern Factories

A CNC lathe machine doing its job is more than mere machining—it’s a testament to human ingenuity. By combining software intelligence with mechanical precision, these machines empower industries to innovate faster, produce smarter, and meet the demands of a rapidly evolving world. Whether crafting a tiny medical screw or a massive turbine shaft, the CNC lathe remains an unsung hero of manufacturing, turning raw potential into polished perfection.

Interested in integrating CNC lathes into your production line? Explore the latest advancements—like multi-axis turning and AI-driven predictive maintenance—to future-proof your manufacturing capabilities.

Keywords for SEO: CNC lathe machine, precision turning, automated machining, CNC machining process, how CNC lathe works, computer numerical control, industrial lathe operation, manufacturing technology, high-tolerance parts, metal turning.

By showcasing the CNC lathe’s role in transforming raw material into precision parts, this article targets businesses seeking efficiency-driven solutions while providing valuable insights for engineers and procurement professionals.