Pillow packing process

Meta Description: Discover the essential steps and best practices in the pillow packing process to ensure product safety, efficiency, and customer satisfaction. Learn how to optimize your packing line today!

Keywords:

pillow packing process, pillow packaging, pillow manufacturing, packaging efficiency, packaging quality control, vacuum-sealed pillows, pillow compression, pillow shipping

The Pillow Packing Process: Ensuring Quality, Protection, and Efficiency

The pillow packing process is a critical step in manufacturing that directly impacts product quality, shipping costs, and customer satisfaction. Whether you’re packaging memory foam pillows, down alternatives, or standard bed pillows, a streamlined and optimized packing method ensures that products arrive in pristine condition while minimizing waste and operational costs. In this guide, we break down the key stages of the pillow packing process and share industry best practices.

Why the Pillow Packing Process Matters

Pillows are lightweight but bulky, making them challenging to ship cost-effectively. Poor packing can lead to:

- Damage during transit (e.g., moisture, compression, or tears).

- Increased shipping fees due to inefficient use of space.

- Negative customer reviews due to unprofessional presentation.

A well-designed packing process solves these challenges by optimizing space, protecting the product, and enhancing brand credibility.

Step-by-Step Breakdown of the Pillow Packing Process

1. Pre-Packing Preparation

- Quality Inspection: Before packing, pillows undergo a final visual and tactile inspection to ensure no defects (stains, uneven filling, or loose seams).

- Fluffing and Shaping: Pillows are fluffed to restore loft and ensure consistent shape, optimizing compression later.

- Tagging and Labeling: Attach brand labels, care instructions, and compliance tags (e.g., fire safety certifications).

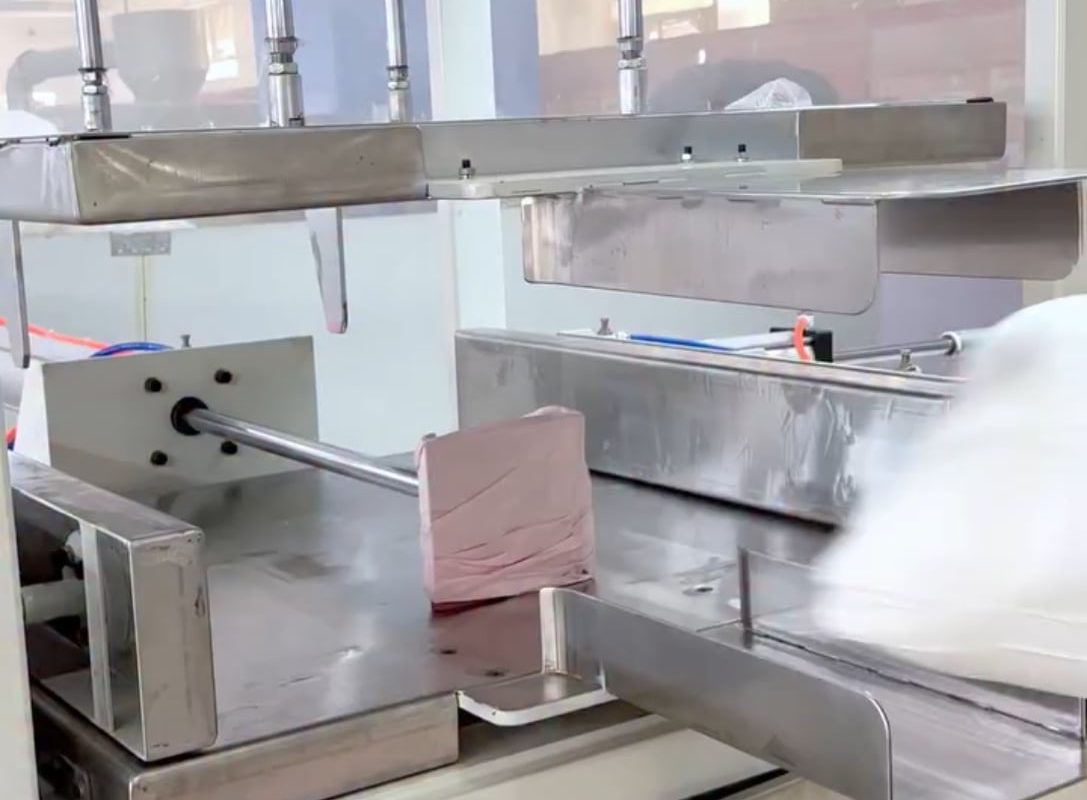

2. Compression and Folding

Most pillows are compressed to reduce volume for shipping and storage. Two common methods include:

- Vacuum Sealing: Pillows are placed in airtight poly bags, and air is vacuumed out, shrinking them to 20–50% of their original size. Ideal for memory foam or hypoallergenic pillows.

- **