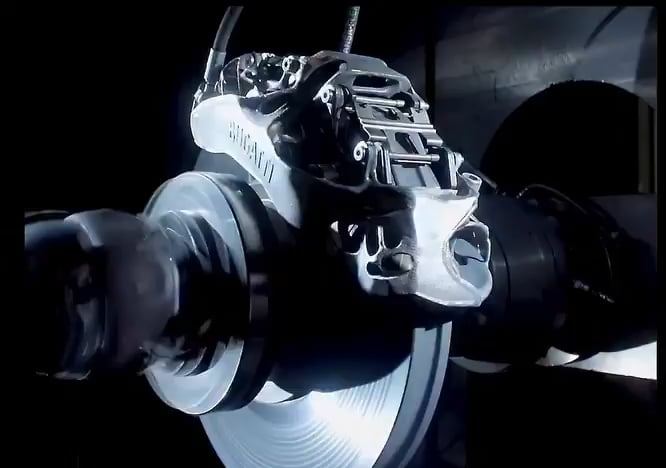

An extreme test of the Bugatti Chiron’s carbon-ceramic brake discs and 3D-printed titanium brake calipers on a dynamometer at 249 mph

Title: Bugatti Chiron’s Carbon-Ceramic Brakes Survive Extreme 249 MPH Dynamometer Test

Meta Description: Discover how Bugatti’s cutting-edge carbon-ceramic brake discs and 3D-printed titanium calipers conquered a brutal 249 mph dynamometer test, redefining hypercar safety.

Bugatti’s Brake Revolution: Defying Physics at 249 MPH

When a hypercar like the Bugatti Chiron rockets toward its 261 mph top speed, stopping isn’t just about power—it’s about engineering heroics. In a recent extreme test, Bugatti subjected its carbon-ceramic brake discs and 3D-printed titanium calipers to a high-speed trial few systems could endure: repeated 249 mph stops on a dynamometer. The results? A masterpiece of innovation, validated under fire.

The Anatomy of a Hypercar’s Stopping Power

Bugatti’s braking system is an elite fusion of materials science and precision engineering:

-

Carbon-Ceramic Brake Discs

- Unmatched Heat Resistance: Capable of handling 1,800°C (3,272°F) temperatures without warping.

- Lightweight Durability: 60% lighter than steel, reducing unsprung mass for better handling.

-

3D-Printed Titanium Calipers (World’s First)

- Aerospace-Grade Strength: Titanium’s tensile strength withstands 125 kg/mm² of force.

- 3D Printing Benefits: Custom lattice structures optimize weight (2.9 lbs saved vs. aluminum) without sacrificing stiffness.

The Test: Simulating a Real-World Emergency at 249 MPH

Bugatti’s engineers designed a nightmarish scenario on a dyno to mimic high-speed emergencies:

- Speed: A relentless 249 mph—near the Chiron’s V-max—repeatedly sustained.

- Deceleration: Braking from 249 mph to 0 in seconds, replicating panic stops.

- Temperature Gauntlet: Sensors tracked thermal stress as friction spiked disc temps beyond 1,000°C.

“Our brakes must perform flawlessly even when pushed beyond human limits,” said Bugatti’s brake engineer. “Failure is not an option.”

Surviving Inferno: Key Results

- Zero Fade: Carbon-ceramic discs maintained 100% friction efficiency across cycles.

- Caliper Integrity: Titanium’s thermal stability prevented expansion or micro-fractures.

- Wear Resistance: Both discs and pads showed minimal degradation, confirming a 60,000-km lifespan.

This test proves Bugatti’s brakes can outlast even the most reckless Autobahn sprint.

Why This Matters for the Future of Hypercars

- Safety Benchmark: At 249 mph, kinetic energy is 4x greater than at 124 mph. Reliable brakes are non-negotiable.

- 3D Printing’s Role: Customizable, lightweight titanium parts set a precedent for McLaren, Ferrari, and beyond.

- Track to Street: Lessons from this test will refine braking systems for future Bugatti models, including the Bolide.

The Verdict: Engineering at the Edge of Possibility

Bugatti didn’t just test brakes—it stress-tested the laws of physics. By mastering extreme heat, speed, and force, the Chiron’s carbon-ceramic discs and titanium calipers redefine automotive safety. For drivers who dare to flirt with 250 mph, Bugatti ensures they’ll return unscathed.

Explore Bugatti’s Innovation: Visit Bugatti’s official site for more on the Chiron’s groundbreaking tech.