Anodizing titanium bolt

The Ultimate Guide to Anodizing Titanium Bolts: Colors, Durability, and Process Explained

Meta Title: Anodizing Titanium Bolts: Step-by-Step Process, Benefits & Uses

Meta Description: Discover how anodizing titanium bolts boosts durability, corrosion resistance, and adds vibrant colors. Learn DIY methods, industrial uses, and FAQs.

Introduction

Titanium bolts are prized for their strength-to-weight ratio and corrosion resistance, making them ideal for aerospace, medical, cycling, and marine applications. But did you know anodizing titanium bolts enhances their performance and aesthetic appeal? This electrochemical process creates a protective oxide layer while allowing for stunning, customizable colors—no paints or dyes needed.

In this guide, you’ll learn:

- What titanium anodizing is and how it works.

- Step-by-step DIY instructions (with safety tips).

- Industrial benefits for engineering and design.

- Answers to top FAQs (durability, color options, and more).

What is Titanium Anodizing?

Anodizing is an electrochemical process that thickens titanium’s natural oxide layer. By submerging titanium in an electrolyte solution and applying voltage, controlled oxidation occurs. This creates a microscopic ceramic coating that:

- 🛡️ Resists corrosion and scratches – perfect for harsh environments.

- 🎨 Generates vibrant colors – via light interference, not pigments.

- ⚡ Improves electrical insulation – critical for aerospace/electronics.

Unlike aluminum anodizing, titanium’s colors depend on voltage, not dyes. Higher voltages produce thicker oxide layers, shifting hues from gold and blue to purple or green.

Why Anodize Titanium Bolts?

1. Enhanced Durability

Anodized bolts withstand saltwater, UV exposure, and chemicals better than raw titanium. The oxide layer acts as a shield, reducing wear in high-stress applications (e.g., motorcycle engines or marine rigging).

2. Lightweight Customization

Anodizing adds color without increasing weight—crucial for racing bikes, drones, or aerospace components. Colors won’t chip or fade like paint.

3. Improved Lubricity

The oxide layer reduces friction, making bolts easier to install and less prone to galling (thread welding).

4. Part Identification

Color-coding bolts simplifies assembly in complex machinery or medical devices.

How to Anodize Titanium Bolts: DIY Guide

Tools & Safety Gear Needed:

- Titanium bolts (Grade 2 or 5 recommended).

- Electrolyte solution (TSP substitute or baking soda/distilled water).

- Power supply (0-120V DC, e.g., battery charger).

- Cathode: Stainless steel or titanium plate.

- Protective gear: Gloves, goggles, and ventilation.

- Cleaning supplies: Acetone, scouring pad.

Step-by-Step Process:

-

Clean Thoroughly

Degrease bolts in acetone and scrub with a non-metallic brush. Contaminants ruin results! -

Etch (Optional)

Dip bolts in a mild acid bath (e.g., 10% hydrofluoric acid) for 10–30 seconds to remove oxides. Always neutralize acid afterward. -

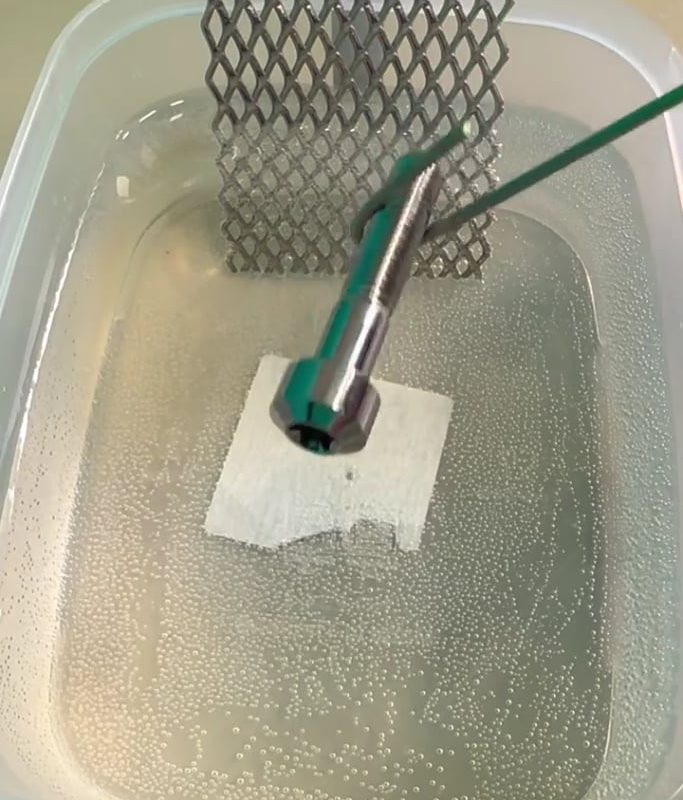

Set Up the Tank

- Fill a plastic container with electrolyte (e.g., 1L water + 5g baking soda).

- Suspend bolts (anode) and cathode in solution without touching.

- Apply Voltage

- Connect bolts to the positive terminal and cathode to negative.

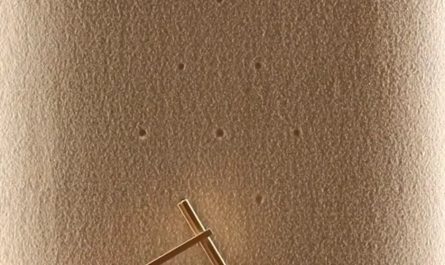

- Slowly ramp up voltage (3V–100V) to achieve colors:

- Bronze/Gold: 15–25V

- Blue: 30–50V

- Purple: 60–80V

- Teal/Green: 90–110V

- Rinse & Dry

After 1–5 minutes, rinse in distilled water and air-dry.

Pro Tips:

- Test voltages on scrap titanium first.

- For gradients, slowly raise voltage during immersion.

- Flame anodizing (using a torch) creates rainbow effects but offers less durability.

Industrial Applications of Anodized Titanium Bolts

- ✈️ Aerospace: Color-coded fasteners for critical assemblies.

- 🚴 Cycling: Custom-colored bolts for high-end bikes.

- 🏥 Medical: Biocompatible bolts for implants/surgical tools.

- ⛵ Marine: Corrosion-resistant hardware for sailboat rigging.

FAQs About Anodizing Titanium Bolts

Q1: How long do anodized colors last?

A: Colors are semi-permanent. They’ll fade only if the oxide layer is mechanically damaged (e.g., sanded).

Q2: Can I anodize titanium at home without a power supply?

A: Flame anodizing uses a torch, but results vary. Electrochemical methods yield consistent, durable colors.

Q3: Are anodized bolts conductive?

A: The oxide layer is non-conductive, making bolts ideal for electrical insulation.

Q4: Which titanium grades anodize best?

A: Commercially pure titanium (Grade 2) and Ti-6Al-4V (Grade 5) respond well.

Conclusion

Anodizing titanium bolts unlocks unparalleled functional and aesthetic benefits. Whether you’re a hobbyist creating rainbow bike parts or an engineer building saltwater-resistant machinery, this process offers lightweight, eco-friendly customization that lasts.

Ready to start? Grab a DIY kit or partner with professional anodizing services for flawless, industrial-grade results.

(Need supplies? Check our recommended [titanium anodizing kits] or [professional finishing services] for quotes.)

Keywords for SEO:

Anodizing titanium bolt, titanium anodizing process, how to anodize titanium, colored titanium bolts, titanium bolt customization, anodized titanium hardware, DIY titanium anodizing.

Image Alt Text Suggestions:

- “DIY titanium bolt anodizing setup with electrolyte tank.”

- “Rainbow anodized titanium bolts for bicycle customization.”

- “Comparison of titanium bolts before and after anodizing.”