Anodizing titanium bolt

Meta Title: Anodizing Titanium Bolts: Benefits, Process & Applications | Ultimate Guide

Meta Description: Discover how anodizing titanium bolts enhances durability, aesthetics, and corrosion resistance. Learn the process, benefits, and DIY tips in our comprehensive guide.

Anodizing Titanium Bolts: The Ultimate Guide to Enhanced Durability & Aesthetics

Titanium bolts are prized in industries like aerospace, medical, and automotive for their strength-to-weight ratio and corrosion resistance. However, anodizing titanium bolts elevates their performance and appearance to new heights. This guide explores the science, benefits, and step-by-step process of titanium anodizing, along with its applications and DIY tips.

Why Anodize Titanium Bolts?

Anodizing is an electrochemical process that thickens titanium’s natural oxide layer, creating a porous surface that can be dyed or sealed for added functionality. Unlike aluminum anodizing, which uses acidic electrolytes, titanium anodizing relies on alkaline solutions or specialized chemicals. Here’s why it’s transformative:

Key Benefits

-

Superior Corrosion Resistance

The anodized oxide layer acts as a barrier against salts, chemicals, and moisture, ideal for marine or industrial environments. -

Stunning Aesthetic Customization

By adjusting voltage during anodizing, titanium bolts can achieve vibrant colors—from gold and blue to purple—without paints or coatings. -

Enhanced Durability & Wear Resistance

Anodizing hardens the surface, reducing scratches and galling (friction-induced welding common in titanium fasteners). -

Electrical Insulation

The oxide layer insulates against electrical conductivity, critical in electronics and aerospace. -

Biocompatibility

Anodized titanium is safe for medical implants, as it prevents metal ion leakage into the body.

The Titanium Anodizing Process Explained

Anodizing titanium bolts involves precise voltage control to grow the oxide layer. Thicker layers diffract light differently, creating color changes.

Step-by-Step Guide

-

Cleaning & Preparation

- Degrease bolts with acetone or isopropyl alcohol.

- Etch the surface in a hydrogen fluoride solution (HF) to remove impurities.

-

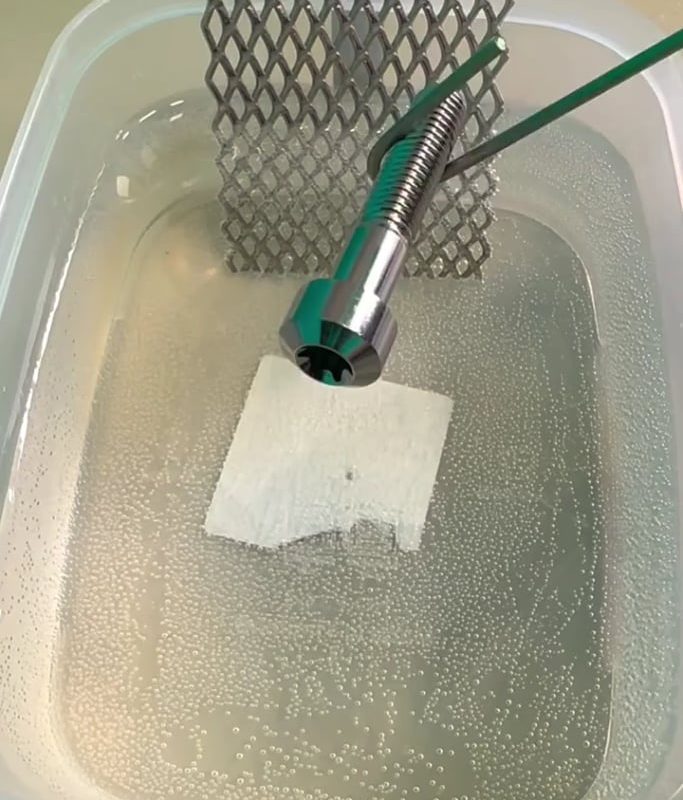

Electrolyte Bath Setup

- Use a non-reactive container filled with an electrolyte like TSP (trisodium phosphate) or borax solution.

- Submerge the titanium bolts and attach them to the anode (+) of a DC power supply.

-

Voltage Application

- Apply DC voltage (typically 20–110V) to achieve desired colors:

- Low Voltage (15–25V): Bronze/Gold

- Medium Voltage (30–50V): Purple/Blue

- High Voltage (60–110V): Teal/Green

- Dip bolts for 10–30 minutes until color stabilizes.

- Apply DC voltage (typically 20–110V) to achieve desired colors:

-

Sealing (Optional)

- Boil bolts in deionized water or seal with wax/clear coat to lock in color and improve corrosion resistance.

Applications of Anodized Titanium Bolts

- Aerospace: Lightweight, non-corrosive fasteners for critical components.

- Medical Devices: Biocompatible screws for implants and surgical tools.

- Automotive & Cycling: High-strength bolts with custom colors for motorsports or bikes.

- Consumer Goods: Eyewear, jewelry, and electronics for aesthetic appeal.

DIY Titanium Anodizing: Tips & Safety

While professionals guarantee consistency, hobbyists can anodize titanium bolts at home:

Tools Needed:

- DC Power Supply (adjustable voltage)

- Electrolyte Solution (e.g., borax or TSP)

- Non-Metal Tongs & Safety Gear (gloves, goggles)

Safety First:

- Work in a ventilated area—avoid inhaling chemical fumes.

- Never mix electrolytes (e.g., HF is highly toxic; borax is safer for DIY).

- Dispose of waste properly—consult local regulations.

Pro Tip: Practice on scrap titanium first! Color results vary based on surface finish and voltage accuracy.

FAQs About Anodizing Titanium Bolts

Q1: Does anodizing weaken titanium bolts?

No! Anodizing is a surface treatment that doesn’t compromise structural integrity.

Q2: How long do anodized colors last?

Colors fade minimally over time but remain vibrant if sealed properly.

Q3: Can I anodize other metals alongside titanium?

No—titanium requires specific voltages and electrolytes. Mixing metals disrupts the process.

Q4: Is DIY anodizing cost-effective?

For small batches, yes. For industrial needs, professional services ensure uniformity and compliance.

Conclusion

Anodizing titanium bolts unlocks a unique blend of beauty and resilience, making them indispensable in high-performance industries. Whether you’re a manufacturer, engineer, or hobbyist, mastering this process elevates your projects to professional standards. For critical applications, partner with certified anodizing services to guarantee flawless results.

Ready to upgrade your titanium fasteners? Explore custom anodizing today and experience the perfect fusion of science and artistry.

Keywords: Titanium bolt anodizing, how to anodize titanium, anodized titanium bolts, titanium anodizing process, benefits of anodized titanium, DIY titanium anodizing, colored titanium bolts.

Image Alt Text: Vibrant anodized titanium bolts in rainbow colors on a workshop table.