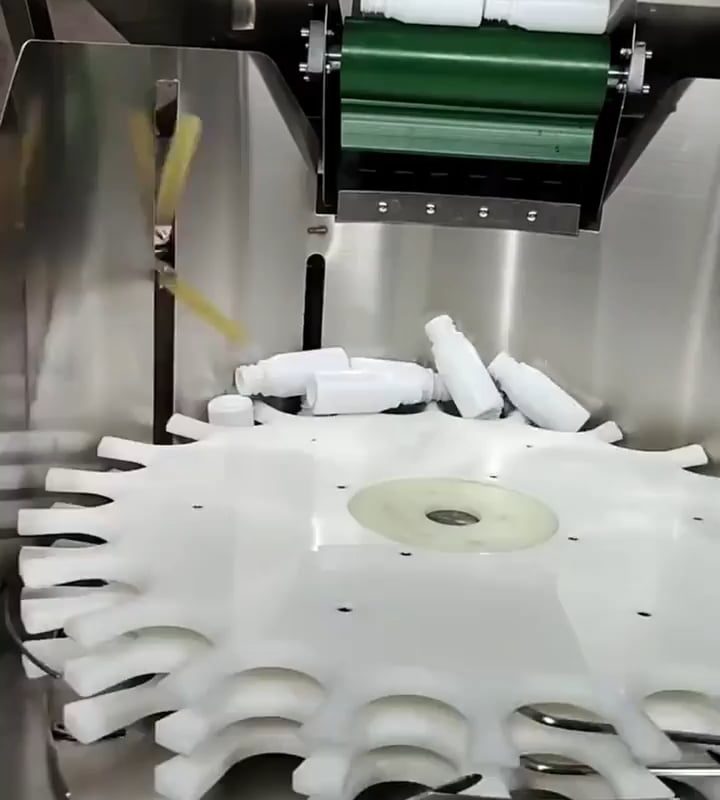

Bottle sorting machine

Meta Description: Discover how bottle sorting machines revolutionize recycling and manufacturing processes. Explore their benefits, working mechanisms, types, and applications in this comprehensive guide.

Headline:

Bottle Sorting Machines: The Future of Efficient Recycling & Manufacturing

Introduction

In an era where sustainability and operational efficiency are paramount, bottle sorting machines have emerged as game-changers for industries like recycling, waste management, and beverage manufacturing. These automated systems streamline the process of separating bottles by material, color, size, and quality, reducing labor costs and errors while boosting productivity. Whether for recycling plants aiming to meet environmental targets or factories optimizing production lines, bottle sorting machines pave the way for a faster, greener future.

What Is a Bottle Sorting Machine?

A bottle sorting machine is an automated system designed to categorize bottles based on predefined criteria such as:

- Material (e.g., plastic, glass, aluminum).

- Color (transparent, green, amber).

- Size or shape.

- Contamination level (e.g., residue, foreign objects).

Using advanced sensors, cameras, and AI-driven software, these machines rapidly identify and separate bottles, ensuring accuracy that manual sorting can’t match.

How Do Bottle Sorting Machines Work?

Modern bottle sorting machines leverage cutting-edge technology to deliver precision:

- Feeding System: Bottles are loaded onto a conveyor belt via hoppers or robotic arms.

- Detection & Scanning:

- Optical Sensors: Analyze color, transparency, and material composition.

- Near-Infrared (NIR) Spectroscopy: Identifies plastic types (PET, HDPE, PP).

- AI Vision Systems: Use machine learning to detect defects or contaminants.

- Separation Mechanism:

- Air jets, robotic arms, or pushers divert bottles into designated bins.

- High-speed systems sort up to 6,000 bottles per hour with 99% accuracy.

- Data Reporting: Many machines collect real-time data for process optimization.

Key Types of Bottle Sorting Machines

Different industries require tailored solutions. Common types include:

-

Glass Bottle Sorters

- Sort by color (clear, green, brown) to maintain glass recycling purity.

- Use lasers or cameras to detect cracks or impurities for quality control.

-

Plastic Bottle Sorters

- Classify plastics by resin type (PET, PVC), ensuring compatibility in recycling.

- Remove caps, labels, and non-recyclable materials.

-

Multi-Material Sorters

- Handle mixed waste streams (e.g., glass, plastic, metal).

- Ideal for municipal recycling centers.

-

High-Speed Industrial Sorters

- Used in beverage manufacturing to reject defective bottles before filling.

Top 5 Benefits of Bottle Sorting Machines

-

Boosted Efficiency

- Automate labor-intensive tasks, speeding up operations by 5–10x.

-

Enhanced Recycling Purity

- Achieve up to 99.9% material purity, meeting strict regulatory standards.

-

Cost Savings

- Reduce manual labor, waste disposal fees, and material waste.

-

Scalability

- Handle small batches or high volumes with modular designs.

-

Sustainability

- Maximize recyclable material recovery, supporting circular economies.

Applications Across Industries

- Recycling Facilities: Sort post-consumer bottles for reprocessing.

- Beverage Manufacturers: Ensure only flawless bottles enter filling lines.

- Waste Management: Improve recovery rates in single-stream recycling.

- Bottled Water Plants: Separate PET bottles by grade for reuse.

Choosing a Bottle Sorting Machine: 5 Key Factors

- Sorting Accuracy: Prioritize systems with AI and NIR for complex tasks.

- Speed: Match throughput (bottles/hour) to your operational needs.

- Versatility: Opt for customizable machines if handling multiple materials.

- Integration: Ensure compatibility with existing conveyor systems.

- Cost vs ROI: Evaluate energy consumption, maintenance, and long-term savings.

The Future of Bottle Sorting Technology

Innovations are driving smarter, more sustainable sorting solutions:

- AI & Machine Learning: Improved defect detection and adaptability.

- Robotics: Collaborative robots (cobots) for flexible sorting lines.

- Blockchain Integration: Trace materials from waste to reuse.

- Compact Mobile Sorters: Deployable in small-scale facilities or emerging markets.

FAQs About Bottle Sorting Machines

Q: Can sorting machines handle crushed or damaged bottles?

A: Yes! Advanced vision systems detect irregular shapes and碎片.

Q: Are these machines eco-friendly?

A: Absolutely—by optimizing recycling, they reduce landfill waste.

Q: What maintenance do they require?

A: Regular cleaning and sensor calibration; most parts are modular for easy replacement.

Conclusion

Bottle sorting machines are no longer a luxury—they’re a necessity for businesses striving for efficiency, sustainability, and competitiveness. By automating the sorting process, these systems minimize human error, cut costs, and ensure materials are recycled or reused effectively. As technology evolves, their role in building a zero-waste future will only grow larger.

Ready to upgrade your operations? Investing in a bottle sorting machine isn’t just smart—it’s a commitment to innovation and environmental stewardship.

Target Keywords:

Bottle sorting machine, automated bottle sorter, plastic sorting machine, recycling sorting system, glass bottle sorter, AI waste sorting.

Optimization Tips:

- Use header tags (H2, H3) with keywords.

- Link to authoritative sources (e.g., EPA recycling guidelines).

- Add internal links to related content (e.g., “How Recycling Robots Work”).

- Include high-quality images/videos of sorting machines in action.