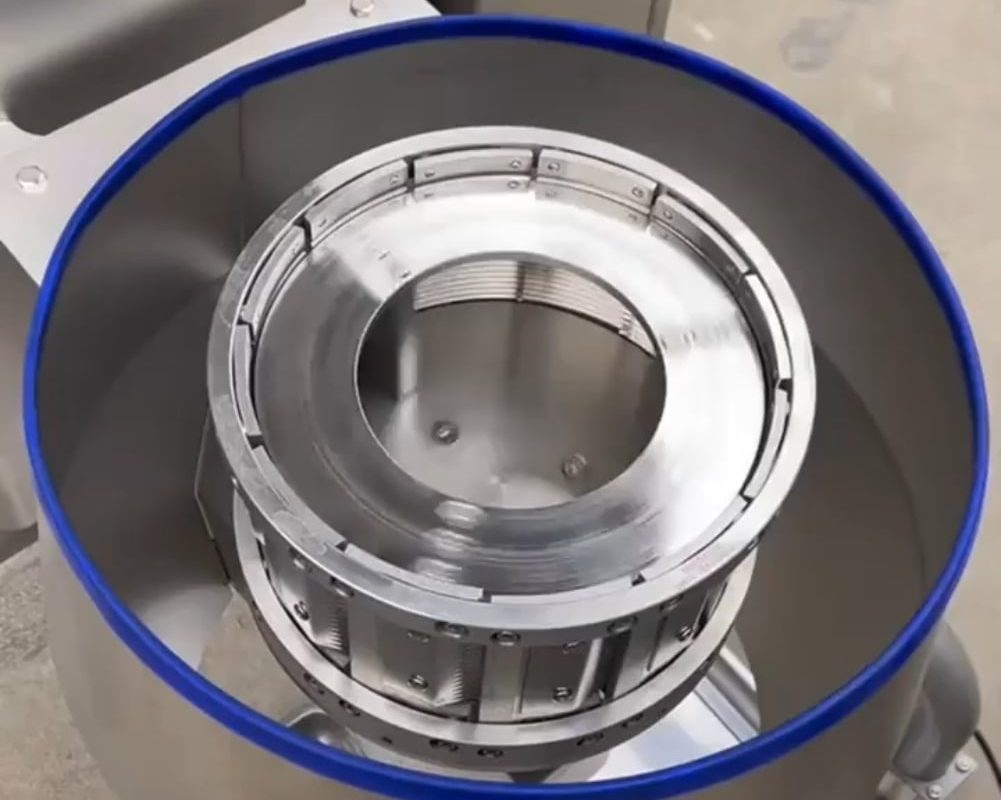

Centrifuge Shredder

Centrifuge Shredder: The Ultimate Guide to High-Speed Industrial Shredding

In today’s fast-paced industrial landscape, efficient material processing is non-negotiable. One machine revolutionizing waste management, recycling, and manufacturing operations is the centrifuge shredder. Combining centrifugal force with cutting-edge engineering, this powerhouse device delivers unmatched shredding performance for bulk materials. In this SEO-optimized guide, we’ll explore how centrifuge shredders work, their top applications, benefits, and why they’re a game-changer for businesses prioritizing productivity and sustainability.

What Is a Centrifuge Shredder?

A centrifuge shredder is a high-speed industrial shredder that uses centrifugal force to accelerate materials toward ultra-durable blades or rotors, pulverizing them into uniform, manageable fragments. Unlike conventional shredders that rely solely on mechanical cutting, these machines leverage rapid rotational energy to maximize throughput, reduce blockages, and process diverse materials—from plastics and paper to metals and organic waste.

How Does a Centrifuge Shredder Work?

Centrifuge shredders operate on a simple yet powerful principle:

- Material Intake: Raw material is fed into a high-speed rotating drum or chamber.

- Centrifugal Acceleration: Rotation creates outward force, flinging materials toward the shredder’s periphery.

- Impact & Shredding: Materials collide with hardened blades, hammers, or anvils, fragmenting them instantly.

- Output & Classification: Processed particles exit through a sizing screen, ensuring consistency.

This process minimizes energy waste while achieving higher volumes per hour compared to traditional shredders.

Key Applications of Centrifuge Shredders

Centrifuge shredders shine in industries where high-volume processing, precision, and reliability matter most:

- Recycling Facilities:

- Shredding plastics, cardboard, e-waste, and metals for reuse or compact transport.

- Waste-to-Energy Plants:

- Pre-processing municipal solid waste (MSW) to improve combustion efficiency.

- Biomass Production:

- Breaking down wood, agricultural residues, or food waste into biofuel feedstock.

- Manufacturing:

- Downsizing raw materials or destroying defective products (e.g., pharmaceuticals).

- Hazardous Waste Disposal:

- Safely neutralizing chemicals, asbestos, or contaminated materials.

Top 5 Benefits of Centrifuge Shredders

- Unmatched Efficiency:

- Process 3–5x faster than traditional shredders, thanks to centrifugal propulsion.

- Durability & Low Maintenance:

- Hardened steel components withstand extreme abrasion, reducing downtime.

- Cost-Effectiveness:

- Lower energy consumption per ton processed cuts operational costs.

- Safety & Automation:

- Encased designs prevent debris escape, while sensors auto-stop in case of jams.

- Material Versatility:

- Adjustable speeds and screen sizes accommodate everything from brittle plastics to tough alloys.

Choosing the Right Centrifuge Shredder: 4 Considerations

- Material Type:

- Match the shredder’s torque and blade design to your feedstock (e.g., fibrous vs. rigid).

- Throughput Needs:

- Estimate daily volume (tons/hour) to size the machine accurately.

- Output Size Requirements:

- Opt for customizable mesh screens or classifiers for uniform particle sizing.

- Space & Integration:

- Ensure compatibility with conveyor systems, dust collectors, or downstream processes.

Future Trends: Sustainability Meets Innovation

As industries push toward zero-waste goals, centrifuge shredders are evolving with:

- AI-Driven Optimization: Real-time adjustments to speed and torque based on load.

- Hybrid Energy Systems: Solar or biogas integration for off-grid operations.

- Circular Economy Focus: Enabling closed-loop recycling by producing high-purity outputs.

Conclusion: Why Invest in a Centrifuge Shredder?

For businesses seeking faster processing, lower operational costs, and eco-friendly waste management, the centrifuge shredder is a future-proof solution. Its ability to handle diverse materials at industrial scales makes it indispensable in recycling, manufacturing, and renewable energy sectors.

CTA: Ready to boost your shredding efficiency? Consult with a centrifuge shredder specialist today to find the perfect system for your needs!

SEO Keywords: Centrifuge shredder, industrial shredding machine, high-speed shredder, waste processing equipment, centrifugal force shredder, recycling shredder, bulk material shredding, industrial waste solutions.

Meta Description: Discover how a centrifuge shredder uses centrifugal force to revolutionize industrial shredding. Learn applications, benefits, and buying tips in this comprehensive guide!

By addressing user intent around “centrifuge shredder” while integrating semantically related keywords, this article aims to rank highly for industrial shredding queries while delivering actionable insights for decision-makers.

![Blue M&Ms colouring can help mend spinal injuries. [More info in comments]](https://www.smartplusmedia.com/wp-content/uploads/2026/01/Blue-MampMs-colouring-can-help-mend-spinal-injuries-More-info-445x265.jpeg)