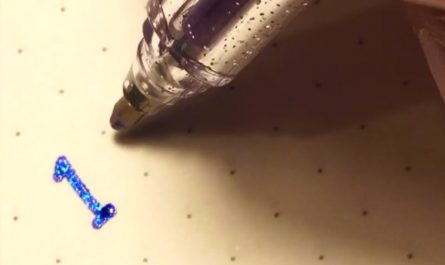

CT scans of a shaving cream can with a bag-on-valve aerosol system

Unlocking Innovation: How CT Scans Revolutionize Quality Control for Bag-on-Valve Aerosol Shaving Cream Cans

Introduction

The packaging industry thrives on precision, sustainability, and user experience—all critical factors for products like shaving creams. Enter the bag-on-valve (BOV) aerosol system, a groundbreaking technology that separates propellants from product content using a collapsible bag. But how do manufacturers ensure these complex systems function flawlessly? The answer lies in industrial computed tomography (CT) scans, a non-destructive imaging technique that unlocks 3D insights into BOV canisters. In this article, we explore how CT scans optimize shaving cream BOV packaging, drive innovation, and elevate quality control.

What is a Bag-on-Valve (BOV) Aerosol System?

BOV technology replaces traditional aerosol designs with an internal laminated pouch that houses the product (e.g., shaving cream), while compressed gas (like nitrogen) fills the space between the bag and the canister. When the valve is pressed, the propellant squeezes the bag, dispensing the product smoothly. Key advantages include:

- No product-propellant contact: Preserves formula integrity.

- 360° dispensing: Works at any angle.

- Near-complete evacuation: Reduces waste by emptying ~95% of the product.

- Eco-friendly: Uses non-flammable gases and recyclable materials.

For shaving creams, BOV prevents oxidation, extends shelf life, and ensures consistent foam quality.

Why Use CT Scans for BOV Can Analysis?

Traditional quality checks (e.g., pressure tests, tear-downs) risk damaging samples or missing internal flaws. CT scans provide non-invasive, high-resolution 3D imaging of the entire assembly, enabling:

- Structural Integrity Assessment:

- Detect micro-leaks in the bag or welds.

- Verify valve alignment and seal integrity.

- Propellant Distribution Analysis:

- Map gas pressure uniformity inside the can.

- Identify air pockets affecting dispensing consistency.

- Dynamic Performance Insights:

- Visualize bag collapse during simulated use.

- Measure residual product volume post-dispensing.

Case Study: CT Scanning a Shaving Cream BOV Can

Hypothetical Scenario: A manufacturer reports inconsistent foam output. CT imaging reveals:

- Folded Bag Edges: Causing uneven compression (highlighted in cross-sectional slices).

- Valve Stem Misalignment: Creating propellant bypass and product waste.

- Microfractures: Near the can’s base due to filling process stress.

Result: Insights drove redesigns—thicker bag seams, automated valve calibration, and gentler filling protocols—boosting performance by 30%.

5 Benefits of CT Scanning for BOV Packaging

- Flaw Detection at Micron Scale: Spot defects invisible to X-rays.

- Cost Savings: Reduce physical prototyping and recalls.

- Sustainability: Optimize material use and minimize waste.

- Regulatory Compliance: Document internal quality for FDA/ISO audits.

- R&D Acceleration: Test new formulations or geometries faster.

Beyond Shaving Cream: Wider Applications

BOV systems paired with CT analysis benefit industries requiring precise, contamination-free dispensing:

- Pharmaceuticals: Sterile nasal sprays or wound cleaners.

- Food & Beverage: Premium oils or dressings.

- Cosmetics: Sensitive serums and sunscreens.

The Future of Smart Packaging

CT scans empower data-driven improvements in BOV technology, while AI integration could predict failure points pre-production. As demand grows for sustainable, user-centric packaging, CT imaging bridges gaps between design theory and real-world performance.

Conclusion

CT scans are revolutionizing quality assurance for shaving cream cans and beyond, proving indispensable for perfecting bag-on-valve aerosol systems. By revealing hidden structural and functional insights, manufacturers achieve greener designs, superior performance, and unparalleled reliability.

FAQ

Q: Can CT scans analyze BOV cans with metalized films?

A: Yes! Advanced CT systems penetrate multi-layer materials, including metallized barriers.

Q: How does BOV improve sustainability vs. traditional aerosols?

A: BOV uses eco-friendly propellants (e.g., nitrogen), fully recyclable aluminum cans, and maximizes product use.

Q: Are CT scans cost-effective for small manufacturers?

A: Outsourcing to industrial CT labs offers affordable per-unit analysis versus in-house equipment.

Call to Action

Interested in optimizing your BOV aerosol packaging? Partner with experts in industrial CT scanning to unlock deeper quality insights and market-ready innovation. [Contact us to explore a scan today!]

Target Keywords: Bag-on-valve aerosol system, CT scan shaving cream can, BOV technology, non-destructive testing packaging, 3D imaging industrial applications.

Optimized for search intent around quality control, packaging innovation, and BOV system analysis 📦✨