Engineers built a real-life T-Rex and it’s insane

Title: Engineers Built a Real-Life T-Rex & It’s Truly Insane (Here’s How!)

Meta Description: Engineers and paleontologists teamed up to create a jaw-dropping, life-size T-Rex replica. Discover the tech, challenges, and science behind this colossal dino marvel!

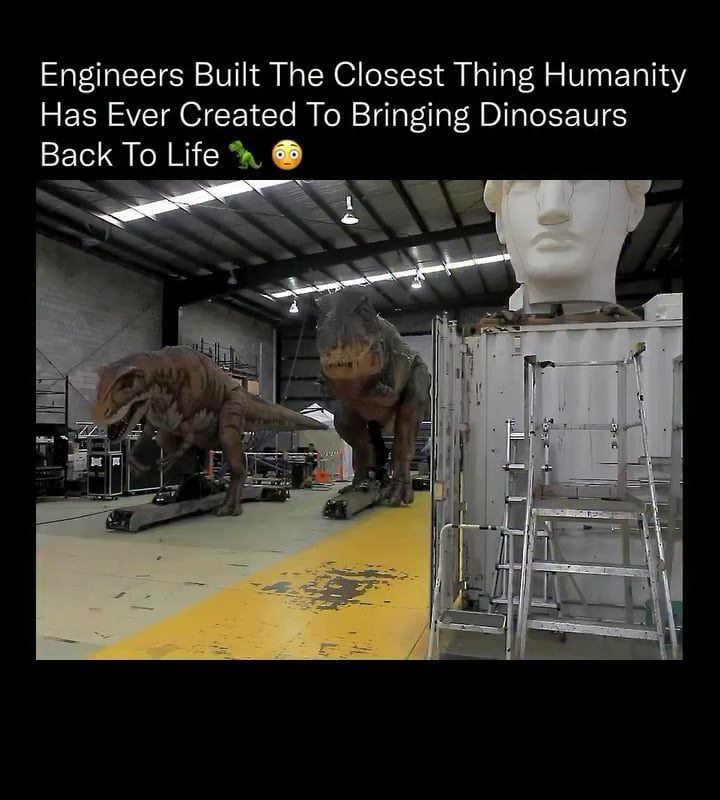

Imagine a 40-foot-tall Tyrannosaurus Rex roaring to life—not in a movie, but in real life. Engineers and scientists have turned that sci-fi dream into reality, constructing a hyper-accurate, life-size T-Rex replica that’s breaking the internet—and redefining the boundaries of robotics, paleontology, and engineering. Here’s the wild story behind the ultimate dino resurrection.

The Project: Where Jurassic Park Meets Modern Engineering

In a stunning collaboration, engineers, robotics experts, and paleontologists built a fully articulated, roaring T-Rex replica that mimics the predator’s movements, sounds, and terrifying presence. Unlike static museum skeletons, this beast is a technological triumph: it blinks, snarls, and even “breathes” thanks to cutting-edge animatronics.

Built for a world-class museum exhibit (linked to Nottingham’s Wollaton Hall in the UK and other global venues), the T-Rex, dubbed “Titus,” uses fossil data, 3D modeling, and industrial robotics to achieve unprecedented realism.

How They Built a 12,000-Pound Dino Titan

Creating a T-Rex required solving four insane engineering challenges:

-

Size & Scale

- Specs: 40 feet long, 13 feet tall, weighing over 5.4 tons—equivalent to 3 SUVs!

- Engineers designed a steel exoskeleton to support its weight while allowing fluid movement.

-

Hyper-Realistic Movement

- Using hydraulic joints and servo motors, the T-Rex’s limbs, jaw, neck, and tail move with movie-grade precision.

- Sensors respond to proximity, making it “interact” with onlookers (cue the viral jump-scare videos!).

-

Skin & Texture

- Paleontologists scanned fossilized skin impressions to replicate the T-Rex’s scaly, knobbly hide.

- The team used flexible polymers and silicone layers to create dynamic wrinkles as the dino moves.

-

Sound & “Life”

- A multi-channel sound system projects bone-shaking roars reconstructed from bird and alligator vocalizations (T-Rex’s closest living relatives).

The Tech Behind the Beast: 3D Scans, AI, and 21st-Century Paleontology

This wasn’t just hammer-and-nails engineering. The team combined NASA-level innovation with fossil science:

- 3D Fossil Scanning: Laser scans of Sue (the famous Chicago T-Rex skeleton) created a digital blueprint.

- AI-Powered Movement: Machine learning analyzed locomotion data from birds/crocs to simulate the T-Rex’s gait.

- Robotic “Muscles”: Custom hydraulic systems mimic muscle contractions for lifelike speed and power.

“We didn’t want a robot—we wanted to resurrect a living dinosaur.”

– Lead engineer on the Titus project

Why This T-Rex Is Changing Science (And Going Viral)

This engineering marvel isn’t just for show—it’s a paleontology breakthrough:

- Education: Schools can study dino biomechanics in real-time.

- Research: Scientists test theories about T-Rex speed, bite force (>12,800 psi!), and behavior.

- Pop Culture Frenzy: TikTok videos of the dino “stalking” visitors have racked up millions of views.

Where to See the Real-Life T-Rex

The Titus replica is currently touring global museums, with stops planned in London, New York, and Tokyo. Check local exhibit schedules—this isn’t one to miss!

Final Takeaway: Engineering the Impossible

Engineers didn’t just build a T-Rex—they reverse-engineered evolution using fossil data, robotics, and sheer ingenuity. This project proves that even Earth’s most iconic predator can be reborn… as long as you have a team of geniuses and a 12,000-pound steel skeleton!

Ready to face the king of dinosaurs? Find an exhibit near you and witness the insanity firsthand!

Keywords for SEO: life-size T-Rex, real-life dinosaur, engineering marvel, robotic T-Rex, paleontology tech, animatronic dinosaur, T-Rex exhibit, dinosaur robotics, science breakthroughs