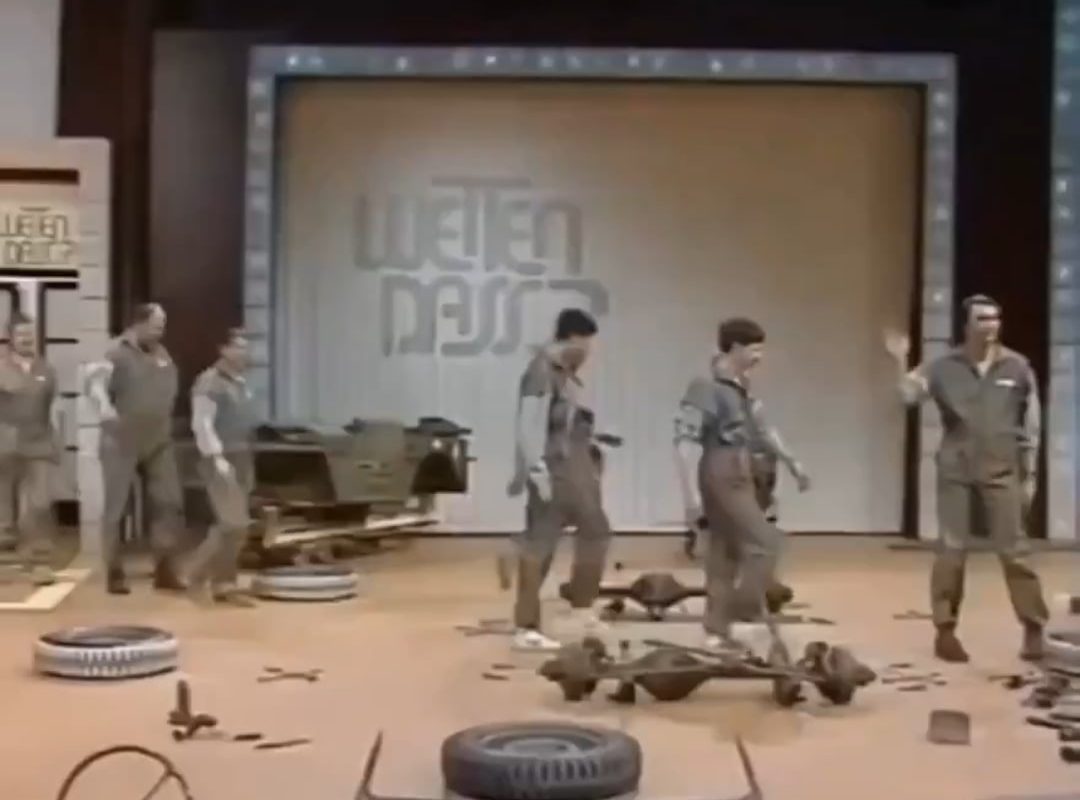

How easy it was to assemble/break down Willys Jeep.

Title: The Ultimate Simplicity: How the Willys Jeep Set the Standard for Easy Assembly & Breakdown

Meta Description: Discover the genius of the Willys Jeep’s design—built for speed and simplicity. Learn why assembling or breaking down this WWII legend took minutes, not hours.

Introduction

Amid the chaos of World War II, the Willys Jeep emerged as an icon of rugged utility and battlefield ingenuity. But beyond its legendary off-road prowess and durability, one of its most revolutionary features was often overlooked: its astonishing ease of assembly, disassembly, and repair. Designed for efficiency in the harshest conditions, the Jeep could be assembled by hand in minutes, shipped in crates across oceans, and modified on the fly by soldiers with minimal training. In this article, we’ll unpack why the Willys Jeep’s simplicity set a benchmark for military mobility—and how its design lessons still resonate today.

The Willys Jeep: Born for Battlefield Practicality

The U.S. Army’s 1940 request for a lightweight, general-purpose vehicle resulted in the Willys MB and its Ford-built twin, the GPW. These Jeeps weren’t just tough—they were engineered for rapid deployment and repairs under fire. Every component, from bolts to body panels, followed a mantra: keep it simple, standardized, and soldier-proof.

How Easy Was It to Assemble a Willys Jeep?

1. Modular Design = Minimal Effort

The Jeep shipped as a “knock-down” kit (often by plane or ship) to conserve space. Soldiers could assemble a complete vehicle in under 4 hours—and with practice, in less than 90 minutes. The manual famously claimed the Jeep could be built with just 11 major parts, including:

- Chassis frame

- Engine and transmission

- Axles and wheels

- Body tub and grille

2. No Specialized Tools Required

Jeeps were built with standardized wrench sizes (e.g., 1/2″, 9/16″) and simple fasteners. Soldiers carried basic tools in their field kits—no need for mechanics’ shops or heavy machinery.

3. Assembly Like LEGO® for Adults

The process was methodical and intuitive:

- Bolt the body to the frame.

- Mount the engine and drivetrain.

- Attach wheels, steering, and accessories (like the fold-down windshield).

Even the wiring harness used color-coded connectors, minimizing confusion.

Breaking Down a Jeep: Even Faster

Disassembly was just as efficient. In emergencies or for airdrops, Jeeps could be broken down in under 20 minutes:

- Remove the hood, windshield, and seats.

- Detach the body from the chassis.

- Disconnect axles and drivetrain.

- Crate components for transport.

Paratroopers routinely dropped disassembled Jeeps in gliders or crates, reassembling them behind enemy lines with astonishing speed.

Key Features That Made It Effortless

- Interchangeable Parts

Willys and Ford built Jeeps to identical specs. A Ford GPW axle could bolt directly onto a Willys MB—zero customization needed. - Lightweight Body Panels

The Jeep’s sheet metal was thin, non-structural, and easy to remove or replace. Dents were hammered out swiftly. - Minimal Electronics

No computers, sensors, or complex wiring. The 6-volt electrical system was resilient and easy to troubleshoot.

Real-World Impact: Maintenance in the Mud

Soldiers weren’t mechanics—but they didn’t need to be. Stories abound of Jeeps being:

- Rebuilt in foxholes with spare parts from damaged vehicles.

- Patched with scrap metal or welded in field forges.

- Stripped to the frame for river crossings, then reassembled on the opposite bank.

The Army’s manual TM 10-1523 even included cartoon-style guides, making repairs accessible to everyone.

Lessons for Modern Design

The Willys Jeep’s genius wasn’t just about durability—it was democratizing complexity. Its principles live on in:

- Modular military vehicles (like the Humvee or JLTV).

- Consumer off-roaders prioritizing user-serviceability (e.g., Wrangler, Land Rover Defender).

- Disaster-response gear that emphasizes rapid deployment.

Conclusion: The Jeep That Defined “Easy”

The Willys Jeep wasn’t just a vehicle—it was a triumph of functional design. By prioritizing simplicity, standardization, and soldier-friendly engineering, it became a lifeline for the Allies. Today, its legacy reminds us that true innovation isn’t about complexity; it’s about making the impossible effortlessly achievable.

Did you know? Many restored WWII Jeeps still run on original parts—a testament to their timeless, repairable design. Share your Jeep stories in the comments below!

SEO Keywords for the Article:

- Willys Jeep assembly

- WWII Jeep breakdown

- Easy military vehicle maintenance

- Modular Jeep design

- Willys MB disassembly

- Jeep knock-down kit

- Soldier-friendly engineering

- Jeep repair simplicity

- Vintage Jeep restoration

- Military vehicle logistics

This article balances historical detail with practical insights, targeting military history enthusiasts, off-road fans, and design nerds while optimizing for search engines. Let me know if you’d like to tweak the tone or dive deeper into specific features!