How gold leaf is made, circa 1965

Title: How Gold Leaf Was Made in 1965: A Look into Vintage Craftsmanship

Meta Description: Discover the intricate, labor-intensive process of crafting gold leaf in 1965, from alloying gold to the final delicate sheets used by artisans.

Introduction

Gold leaf, the shimmering material used for gilding art, architecture, and luxury objects, has been treasured for millennia. By 1965, its production remained rooted in centuries-old traditions, blending meticulous handcraftsmanship with early industrial techniques. This article dives into the fascinating process of how gold leaf was made during this era, shedding light on an art form that still captivates today.

The Ingredients: Alloying Pure Gold

Pure gold (24 karats) is too soft for practical use, so craftsmen in 1965 began by alloying it with tiny amounts of silver or copper. This strengthened the gold while preserving its dazzling luster. The ratio depended on the desired color—more silver created a pale gold, while copper added warmth. The alloy was melted in a crucible and poured into molds to form ingots.

Step 1: Rolling the Gold into Ribbon

The cooled ingot was passed through a hydraulic rolling mill repeatedly, transforming it into a thin ribbon roughly 1/1000th of an inch thick. This stage required precision: workers gradually reduced the mill’s gap to avoid tearing the gold. By the end, the ribbon was thin enough to see through but still too thick for leaf-making.

Step 2: Cutting the Gold into Squares

Using specialized cutting machines, the gold ribbon was sliced into 1-inch squares called “cuts.” Each square was layered between sheets of Japanese mulberry paper or parchment, creating a “pack” of 100–200 pieces. This protective sandwich prepared the gold for the most crucial step: beating.

Step 3: The First Beating (Machine Hammering)

Packs of gold squares were placed in a “shoder” machine, an industrial version of the traditional hammering process. The machine slowly pounded the pack for up to 4 hours, stretching each cut into a thin, uneven disc roughly 8–10 inches in diameter. At this stage, the gold leaf was still irregular in thickness and full of microscopic holes.

Step 4: Hand-Beating & Final Thinning

For ultra-fine gold leaf (used in delicate art restoration or luxury gilding), artisans resumed the process by hand. Using wooden-framed mallets, master craftsmen rhythmically hammered the gold-packed parchment for hours, thinning it to 0.1 microns (1/10,000th of a millimeter!). The gold’s final thickness varied:

- Single-thickness leaf: ~0.14 microns

- Double-thickness leaf: ~0.28 microns

Due to its fragility, this step required a draft-free, humid workspace to prevent tearing.

Step 5: Assembling Gold Leaf Books

Once beaten, the gold leaf was carefully separated and sandwiched into “gold leaf books.” Each book contained 25 sheets interleaved with tissue paper. The leaves were trimmed to standard sizes (e.g., 3⅜” x 3⅜”), though custom dimensions existed for specialty projects.

Why 1965 Was Unique

- Hybrid Methods: While machines handled initial thinning, artisans still dominated final stages.

- Material Innovations: Mulberry paper, traditional animal-skin parchment, and synthetic alternatives coexisted, balancing cost and quality.

- Cultural Demand: Gold leaf flourished in post-war restoration projects, religious artifacts, and mid-century modernist decor.

Quality Control: Testing the Gold Leaf

Quality checks in 1965 included:

- Color Consistency: Matching alloy batches to prior productions.

- Transparency Test: Holding a leaf to light—uniform opacity signaled quality.

- Durability: Testing flexibility and resistance to crumbling.

Flares or dark spots indicated impurities, resulting in discard.

Applications of 1965 Gold Leaf

Gold leaf wasn’t just decorative—it was functional:

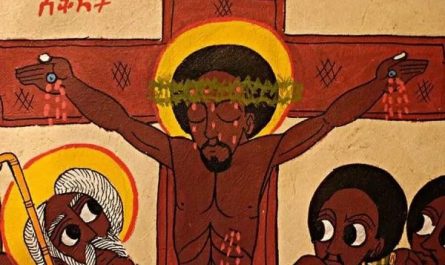

- Sacred Spaces: Gilding church domes, altars, and icons.

- Architecture: Highlighting details on monuments and luxury buildings.

- Art & Furniture: Illuminating frames, sculptures, and mid-century lacquerware.

Legacy of Vintage Gold Leaf Production

The 1965 process mirrored Renaissance techniques but laid groundwork for modern automation. Today, gold leaf remains a symbol of luxury, though most is now machine-made. Yet traditional workshops preserve the analog methods, honoring an art perfected in an era of craftsmanship.

Conclusion

Gold leaf production in 1965 was a marriage of patience, skill, and emerging technology. From molten alloy to tissue-thin sheets, every stage demanded precision to create a material synonymous with grandeur. Whether adorning a masterpiece or a cathedral, gold leaf reminds us that some arts refuse to fade—even in a world racing toward automation.

Keywords: gold leaf making 1965, vintage gold leaf process, how gold leaf was made, traditional gilding, gold beating method, historic gold production, gold leaf craftsmanship