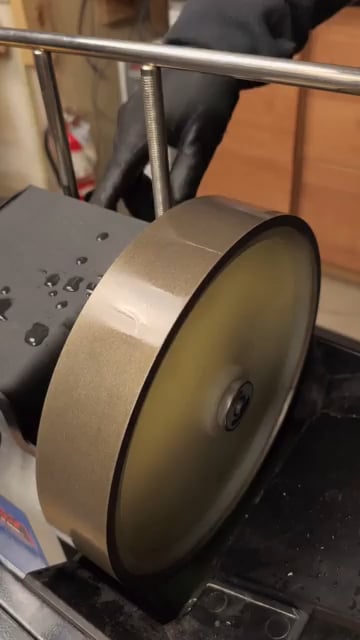

Knife grinding machine

Knife Grinding Machines: A Comprehensive Guide to Precision Sharpening

Introduction

In industries where sharp blades are mission-critical—from woodworking and metal fabrication to food processing and packaging—knife grinding machines are indispensable tools. These machines automate the blade-sharpening process, ensuring precision, consistency, and efficiency while reducing manual labor costs. Whether you’re a manufacturer, a small workshop owner, or a hobbyist seeking professional-grade results, understanding how knife grinding machines work and their benefits can transform your operations.

This guide dives deep into knife grinding machines, covering types, key features, applications, and tips for choosing the right model for your needs.

What Is a Knife Grinding Machine?

A knife grinding machine is a specialized piece of equipment designed to sharpen and maintain the edges of industrial blades. Unlike manual sharpening methods, these machines use abrasive wheels, belts, or discs to grind blades to precise angles and finishes. They’re engineered for:

- Accuracy: Consistent edge angles (±0.1° tolerance).

- Speed: Sharpening in minutes vs. hours.

- Versatility: Adaptability to different blade shapes (straight, curved, serrated).

- Safety: Reduced risk of operator injury compared to handheld tools.

Types of Knife Grinding Machines

1. Automatic Knife Grinders

- Ideal for high-volume production.

- Fully programmable for complex blade profiles.

- Used in paper mills, printing, and textile industries.

2. Manual/Semi-Automatic Grinders

- Budget-friendly for small businesses.

- Operated via hand cranks or foot pedals.

- Common in workshops sharpening planer blades or kitchen knives.

3. CNC Knife Grinders

- Computer-controlled precision for custom geometries.

- Perfect for aerospace or medical blade manufacturing.

- Features automated tool-changing and real-time adjustments.

4. Portable Grinders

- Compact units for on-site maintenance (e.g., agriculture or forestry).

- Often run on batteries or low-power motors.

Key Features to Consider When Buying

Choosing the right knife grinder depends on your workflow. Prioritize these factors:

- Grinding Method: Belt, wheel, or disc grinding—each affects finish quality and speed.

- Power and RPM: Higher RPM (3,000–6,000) suits hard metals; low RPM avoids overheating.

- Adjustability: Look for angle guides, adjustable rests, and tilting worktables.

- Coolant Systems: Prevent blade warping with integrated coolant or misting.

- Durability: Cast-iron or steel frames ensure stability for heavy-duty use.

- Safety Features: Emergency stops, shields, and dust extraction ports.

Top Applications Across Industries

- Food Processing: Sharpening slicer blades for meat, poultry, and vegetables.

- Woodworking: Maintaining planer, chipper, and jointer knives.

- Packaging: Trimming rotary blades for cardboard, plastic, and foil.

- Metalworking: Sharpening shear blades and industrial cutters.

- Printing: Precision grinding of slitter-scorer blades.

Benefits of Using a Knife Grinding Machine

- Extended Blade Lifespan: Regular sharpening reduces replacement costs by up to 50%.

- Enhanced Productivity: Automate repetitive tasks to focus skilled labor elsewhere.

- Superior Finish: Mirror-polished edges reduce friction, improving cut quality.

- Cost Savings: Eliminate outsourcing for blade maintenance.

- Eco-Friendly: Sharpen instead of discarding dull blades.

Maintenance Tips for Long-Term Performance

- Clean grinding residue daily to prevent buildup.

- Lubricate moving parts weekly.

- Replace abrasive wheels/belts as soon as wear is visible.

- Calibration checks every 3–6 months to maintain accuracy.

How to Choose the Best Knife Grinding Machine

- Assess Your Volume: High-output shops need automation; low-volume users can opt for manual models.

- Blade Material: Carbide-tipped blades require diamond-coated abrasives.

- Space Constraints: Benchtop grinders suit tight spaces; floor models handle larger blades.

- Budget Balance: Entry-level machines start at $500; industrial CNC units exceed $20,000.

FAQs About Knife Grinding Machines

Q: Can I sharpen ceramic blades with a standard grinder?

A: No—ceramic requires diamond-embedded grinding wheels due to extreme hardness.

Q: How often should industrial blades be sharpened?

A: Frequency depends on usage, but most blades need sharpening after 40–80 hours of work.

Q: Are knife grinders noisy?

A: Noise levels vary, but modern models include vibration dampeners for quieter operation (70–85 dB).

Conclusion

Investing in a knife grinding machine is a strategic move for any business relying on sharp blades. With options ranging from portable sharpeners to fully automated CNC systems, there’s a solution for every budget and production scale. By improving edge consistency, reducing downtime, and slashing operational costs, these machines deliver a rapid ROI while ensuring your blades remain in peak condition.

Ready to optimize your sharpening process? Evaluate your needs, explore top brands like Darex, Kent Industrial, and WEN, and step into the future of precision blade maintenance.

SEO Keywords: Knife grinding machine, blade sharpening machine, industrial knife grinder, CNC knife grinder, portable knife sharpener, automatic knife grinder, industrial blade maintenance, knife grinding machine for sale.

Meta Description: Discover how knife grinding machines boost efficiency and precision in blade maintenance. Learn types, benefits, buying tips, and applications in this detailed guide.