Machining an Egg with cnc machine

Title: Precision Beyond the Shell: The Fascinating Challenge of Machining an Egg with a CNC Machine

Meta Description: Explore the extreme precision of CNC machining by attempting the ultimate challenge: carving an egg. Learn the process, tools, and surprising applications of this delicate feat.

Can You Machine an Egg with a CNC Machine? The Ultimate Test of Precision

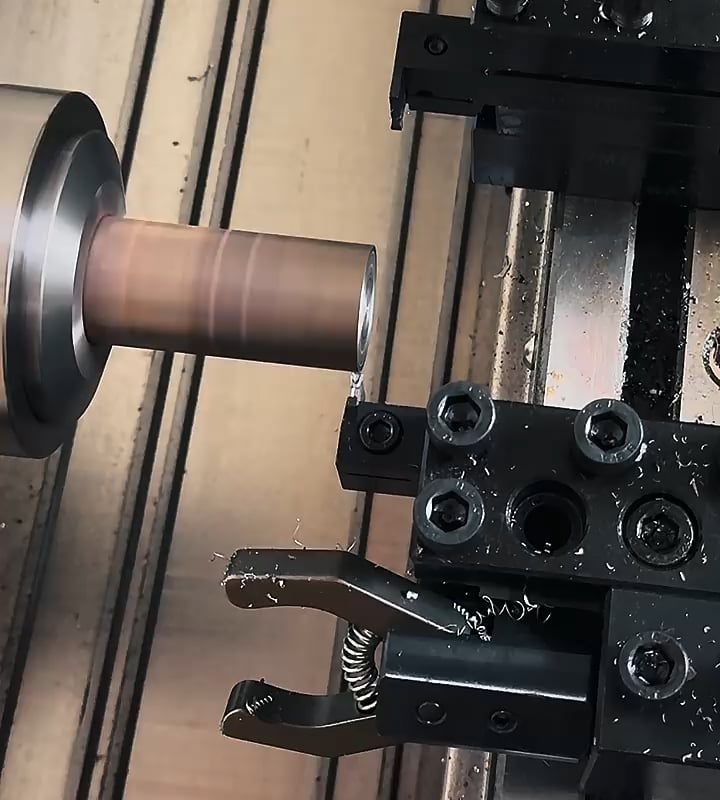

CNC (Computer Numerical Control) machining is renowned for transforming raw materials into complex, high-tolerance parts. But what happens when you push this technology to its limits by machining one of nature’s most fragile objects—a raw egg? This quirky experiment isn’t just a viral video gimmick; it’s a masterclass in precision, tool selection, and creative problem-solving.

In this article, we’ll crack into:

- Why machining an egg challenges even advanced CNC systems.

- Step-by-step methods to avoid splatter disasters.

- Real-world applications for ultra-delicate CNC projects.

The Egg Machining Challenge: Why It’s Surprisingly Difficult

An egg’s shell is a marvel of natural engineering—0.3mm thin, curved, brittle, and uneven. Machining it without obliterating the shell or rupturing the liquid interior demands near-flawless execution. Here’s what complicates the process:

- Material Fragility: Eggshells fracture under minuscule pressure variances.

- Geometry: Curved surfaces require dynamic toolpath adjustments.

- Contamination Risk: Egg white/yellow can gum up tools and workholding.

- Vibration Sensitivity: Even slight machine tremor spells disaster.

Tools & Setup: How to Machine an Egg (Without Making Omelets)

To pull this off, machinists use specialized strategies:

✅ Material Prep: Fake Eggs FTW

Most experiments start with 3D-printed or synthetic eggs made of plastic, wax, or resin. These mimic an egg’s shape while eliminating mess. For raw eggs, freezing solidifies the interior temporarily.

✅ Workholding Solutions

- Vacuum Chucks: Gently secure the egg without crushing.

- Custom Soft Jaws: Molded to the egg’s contour.

- Adhesive Putty: Temporary fixation (used cautiously!).

✅ Tooling Choices

- Micro End Mills: Diamond-coated bits under 1mm diameter.

- High RPM Spindles: 20,000+ RPM minimizes vibration.

- Laser or Waterjet: Non-contact methods for etching patterns.

✅ CNC Parameters

- Feed Rate: As low as 50–100 mm/min.

- Depth of Cut: 0.05mm or less per pass.

- Coolant: Compressed air to clear debris without moisture.

Step-by-Step Egg Machining Process

-

3D Scan the Egg

Use a probe or laser scanner to create a precise digital model. -

CAM Programming

Generate toolpaths optimized for curves (e.g., radial finishing). Avoid abrupt Z-axis moves. -

Mock Testing

Run the program on a synthetic egg to debug collisions. -

Machining

- Secure the egg vertically or horizontally.

- Execute ultra-shallow, high-speed passes.

- Pause frequently to inspect for hairline cracks.

-

Post-Processing

Sand edges with 1000+ grit paper or use chemical polishing.

👉 Video Alert: Check out Tech Ingredient’s viral CNC egg experiment for a live demo!

Applications: Why Bother Machining an Egg?

Beyond the “because we can” bragging rights, this exercise has real-world implications:

- Medical Device Prototyping: Machining delicate biocompatible materials.

- Aerospace: Testing tolerances for thin-shelled components (e.g., turbine blades).

- Art & Jewelry: Crafting intricate sculptures or pendants.

- Education: Demonstrating CNC’s precision limits in workshops.

Key Takeaways & Pro Tips

- Start Synthetic: Practice on wax/plastic before attempting real eggs.

- Monitor Temperature: Heat from friction can weaken shells—use cryogenic cooling for raw eggs.

- Safety First: Seal the workspace to contain egg shrapnel!

Final Verdict: Yes, It’s Possible (But Not Easy)

Machining an egg showcases CNC’s astonishing precision—and its fragility when faced with nature’s design. While industrial shops won’t prioritize egg carving, the techniques learned (micro-tool mastery, vibration dampening, and curved-surface toolpaths) translate to critical high-end applications.

In the battle between CNC and egg, both come out stronger.

Ready to Test Your CNC Skills?

Share your egg machining attempts with #CNCEggChallenge! For more unconventional projects, explore our guides on Machining Chocolate or Wood CNC Art.