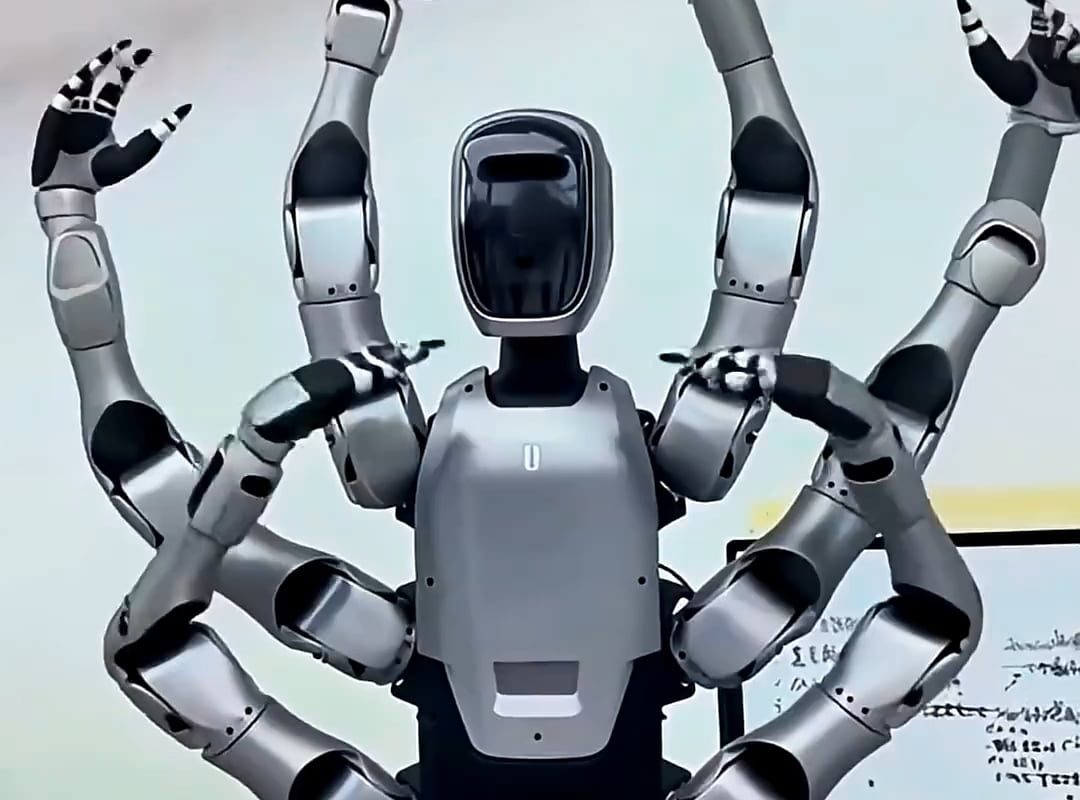

Midea’s new 6-armed industrial robot to handle simultaneous tasks in factories

Title: Revolutionizing Manufacturing: Midea Unveils 6-Armed Industrial Robot for Multitasking Factory Automation

Meta Description: Discover how Midea’s groundbreaking 6-armed industrial robot is transforming factory efficiency by handling simultaneous tasks, boosting productivity, and cutting costs.

Introduction: The Future of Factory Automation is Here

As industries worldwide push for faster, smarter, and more adaptable manufacturing processes, Midea Group has once again positioned itself at the forefront of innovation. The家电巨头’s latest release—a 6-armed industrial robot—promises to redefine productivity on factory floors. Designed to execute multiple tasks simultaneously with surgical precision, this robot aims to eliminate bottlenecks, reduce labor costs, and accelerate the shift toward fully automated “smart factories.”

In this article, we’ll explore how Midea’s revolutionary robot works, its key benefits, and the industries set to gain the most from its deployment.

What Sets Midea’s 6-Armed Robot Apart?

Unlike traditional single-arm robots that handle one operation at a time, Midea’s hexapod robot boasts six fully independent robotic arms integrated into a single unit. Each arm functions autonomously or in sync with others, enabling it to:

- Perform parallel tasks: Assembly, welding, material handling, and quality inspection can occur simultaneously.

- Adapt dynamically: AI-driven vision systems and sensors allow real-time adjustments to workflow disruptions.

- Maximize floor space: Consolidating multiple robots into one compact system reduces factory footprint.

Powered by Midea’s proprietary Industrial IoT (IIoT) platform, the robot seamlessly integrates with existing production lines, offering plug-and-play compatibility with minimal downtime.

Key Advantages for Modern Factories

1. Unprecedented Productivity Gains

With six arms working in tandem, cycle times can be slashed by up to 50% compared to conventional robots. For example, while one arm assembles components, another can pack finished products and a third conducts inspections—all without waiting for sequential processes.

2. Cost Efficiency

Factories can reduce reliance on multiple single-task robots or human workers for complex workflows. Midea estimates a 20–30% reduction in operational costs over three years, factoring in energy savings and lower maintenance needs.

3. Enhanced Precision & Quality Control

Equipped with AI-powered computer vision, the robot detects microscopic defects in real-time. Its arms operate with ±0.02mm repeatability, minimizing errors in high-precision sectors like electronics or automotive manufacturing.

4. Scalability for Industry 4.0

The robot’s IIoT connectivity enables predictive maintenance, remote monitoring, and data-driven optimization. It aligns perfectly with smart factory ecosystems, where machines communicate to self-optimize production.

Industries Primed for Transformation

Midea’s multitasking robot is a game-changer for sectors requiring speed, flexibility, and precision:

- Automotive: Streamline assembly lines for engines, batteries, or interiors.

- Electronics: Accelerate PCB assembly and smartphone manufacturing.

- Consumer Goods: Optimize packaging, sorting, and palletizing for e-commerce demand.

- Pharmaceuticals: Handle delicate lab equipment and precision filling tasks.

Case studies from pilot factories revealed a 40% increase in output for electronics clients, with zero compromise on quality.

Why This Launch Matters

Midea’s move into advanced robotics highlights its strategic expansion beyond home appliances into industrial automation—a market projected to reach $81.4 billion by 2028 (Grand View Research). Acquiring German robotics leader KUKA in 2016 laid the groundwork for this innovation, blending KUKA’s engineering excellence with Midea’s manufacturing scale.

As labor shortages and supply chain complexities persist, tools like the 6-armed robot offer a sustainable path to reshoring production and meeting rising consumer demands.

The Road Ahead: Collaborative Robotics & Sustainability

Midea plans to evolve this technology further, exploring collaborative robotics (cobots) where humans and robots work side-by-side safely. Additionally, the robot’s energy-efficient design supports green manufacturing goals, consuming 15% less power than equivalent systems.

Conclusion: Embrace the Multi-Tasking Revolution

Midea’s 6-armed industrial robot isn’t just an incremental upgrade—it’s a paradigm shift in how factories operate. By enabling simultaneous, intelligent multitasking, it empowers businesses to do more with less, future-proofing operations in an era of relentless competition.

For manufacturers eyeing higher efficiency, lower costs, and Industry 4.0 readiness, this innovation could be the catalyst to unlock unprecedented growth.

Ready to transform your production line? Stay tuned for Midea’s official product rollout and demos later this year.

Keywords for SEO:

Midea industrial robot, 6-armed robot, factory automation, multitasking robotics, industrial IoT, smart manufacturing, Industry 4.0, KUKA robotics, cost-effective automation, manufacturing efficiency.

Optimize visibility by targeting long-tail keywords like “best robot for simultaneous factory tasks” or “reduce assembly line costs with Midea.”