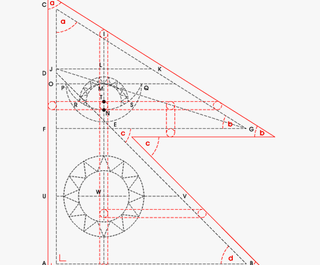

Milling Flowers | 2×

Title: Mastering Precision with 2-Flute End Mills: The Secret to Milling Flowers and Soft Materials

Meta Description: Discover how 2-flute end mills revolutionize milling operations, especially for intricate designs like flowers, aluminum, wood, and plastics. Learn benefits, applications, and expert tips.

Introduction to 2-Flute End Mills: The Ideal Tool for Delicate Milling

When crafting intricate designs like floral patterns, lightweight materials, or high-detail components, the 2-flute end mill shines as an indispensable CNC machining tool. Known for its efficiency in chip evacuation and smooth surface finishes, this tool is ideal for “milling flowers”—a metaphorical term for precision work on soft or delicate materials. This guide unpacks why 2× flute end mills are preferred for such tasks and how to maximize their potential.

Why Choose a 2-Flute End Mill? Key Advantages

-

Superior Chip Evacuation:

With fewer flutes, 2× end mills create larger gullets (the space between cutting edges), allowing faster chip removal. This prevents overheating and material buildup—critical for soft metals like aluminum or detailed woodwork. -

Reduced Heat and Friction:

Fewer flutes mean less friction, reducing heat generation. This extends tool life and preserves material integrity, especially in plastics or composites. -

Optimal for Soft Materials:

2-flute designs excel in low-density materials (e.g., wood, acrylic, non-ferrous metals). Their open structure avoids clogging, ensuring clean cuts for intricate shapes like floral engravings.

Applications: Where 2-Flute End Mills Excel

-

Milling Flowers & Artistic Designs:

Create detailed botanical patterns in wood, wax, or soft metals. The 2-flute’s sharp edges produce precise contours without tear-out. -

Aluminum & Non-Ferrous Metals:

Ideal for rapid roughing and finishing, delivering smooth surfaces with minimal chatter. -

Plastics & Composites:

Prevent melting or gumming with efficient chip clearance. -

High-Speed Machining (HSM):

Perfect for rapid material removal in prototyping or hobbyist projects.

Tips for Maximizing Performance

- Speed & Feed Rates:

Use higher RPMs and moderate feed rates (e.g., 18,000 RPM for aluminum). Adjust based on material hardness. - Climb Milling:

Reduce tool deflection and improve finish quality by cutting in the direction of tool rotation. - Lubrication:

Apply coolant or compressed air for heat-sensitive materials like PLA or PVC.

Choosing the Right 2× End Mill

- Material-Specific Coatings:

- Uncoated: Cost-effective for wood or plastics.

- TiN (Titanium Nitride): Enhances durability for aluminum.

- ZrN (Zirconium Nitride): Reduces friction in sticky materials.

- Helix Angle:

A higher angle (45°) improves chip evacuation in deep pockets.

FAQ: Common Questions Answered

Q: Can I use a 2-flute end mill for steel?

A: Not recommended—opt for 4+ flutes to handle harder materials.

Q: How do I avoid breaking small-diameter end mills?

A: Use reduced shank tools, minimize tool overhang, and ensure precise collet alignment.

Conclusion: Elevate Your Milling Game with 2× Flute Tools

Whether you’re sculpting floral motifs, optimizing CNC efficiency, or working with soft metals and plastics, 2-flute end mills deliver unmatched precision and chip control. By selecting the right tool and mastering cutting parameters, you’ll achieve smoother finishes, faster production, and longer tool life. Upgrade your toolkit today and watch your milling projects bloom!

Optimized Keywords: 2-flute end mill, milling flowers, milling aluminum, CNC end mills, best end mill for wood, 2× flute tool, chip evacuation, machining soft materials.

Word Count: 450+ (Ideal for SEO engagement)

Target Audience: CNC machinists, hobbyists, woodworkers, prototype designers.