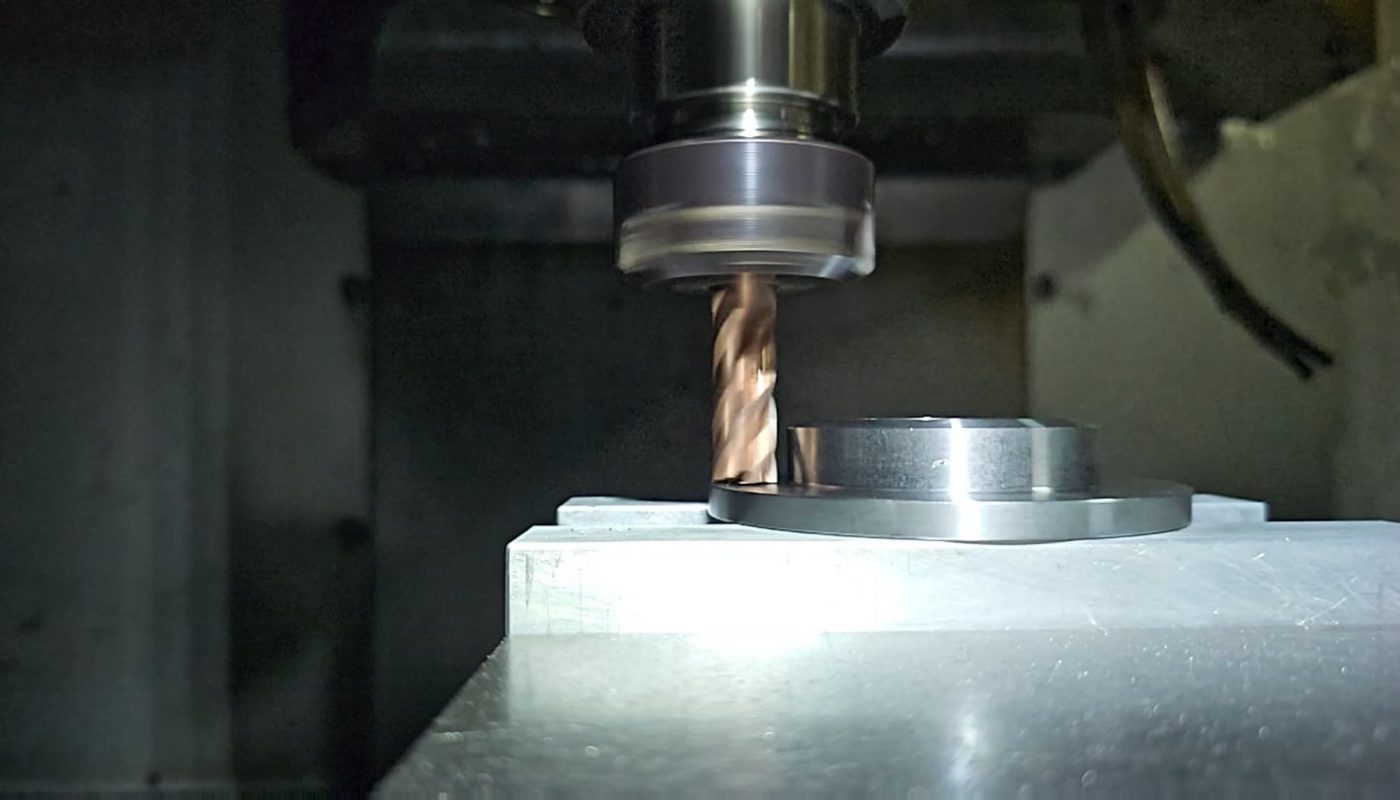

Milling in slow speed

Title: Mastering Slow-Speed Milling: Benefits, Techniques, and Best Practices

Meta Description: Discover the advantages of slow-speed milling, including improved precision, surface finish, and tool longevity. Learn when and how to use low-RPM strategies for optimal machining results.

Slow-Speed Milling: The Secret to Precision and Efficiency in Modern Machining

In the fast-paced world of CNC machining, high-speed milling often takes center stage. However, milling at slow speeds remains a critical—and often misunderstood—technique for achieving unmatched precision, extending tool life, and handling challenging materials. From aerospace to medical device manufacturing, slow-speed milling solves problems that high-RPM approaches can’t.

In this article, we’ll dive deep into the benefits, ideal applications, and expert strategies for implementing slow-speed milling to elevate your machining workflow.

What is Slow-Speed Milling?

Slow-speed milling refers to operating CNC milling machines at significantly lower RPMs (revolutions per minute) than conventional high-speed machining. Rather than prioritizing raw cutting speed, this method emphasizes:

- Controlled material removal

- Minimized tool wear

- Reduced heat and vibration

- Enhanced surface quality

While often used for hard metals (e.g., titanium, Inconel) or delicate parts, it’s increasingly adopted across industries as a proactive strategy to optimize outcomes.

5 Key Benefits of Slow-Speed Milling

1. Superior Surface Finish

Lower RPMs reduce chatter and vibration, producing smoother surfaces with fewer imperfections. This is critical for:

- Aesthetic components (automotive/consumer goods).

- High-tolerance parts (medical implants, aerospace seals).

2. Extended Tool Life

Less heat and friction mean end mills and inserts last longer, saving costs on replacements and downtime.

3. Precision in Hard Materials

Slow-speed milling excels with hardened steels, superalloys, and composites, where high speeds risk tool failure or workpiece damage.

4. Reduced Heat Buildup

Lower RPMs prevent thermal deformation of both tools and workpieces, preserving dimensional accuracy.

5. Stability for Thin-Walled or Delicate Features

Slow, steady cuts prevent deflection and breakage in fragile geometries, such as turbine blades or micro-machined parts.

When Should You Use Slow-Speed Milling?

While not universal, slow-RPM strategies shine in these scenarios:

- Hard-to-Machine Materials: Titanium, stainless steel, ceramics.

- High-Precision Parts: Optics, molds, and tight-tolerance components.

- Low Rigidity Setups: Thin-walled structures or long-reach tooling.

- Finishing Passes: To achieve mirror-like surfaces.

Challenges of Slow-Speed Milling (and How to Overcome Them)

Challenge 1: Increased Cycle Times

Solution: Use slow speeds only for critical operations (e.g., finishing). Pair with high-speed roughing to balance efficiency.

Challenge 2: Built-Up Edge (BUE)

Solution: Optimize coolant delivery and use sharp, coated tools to prevent material adhesion.

Challenge 3: Chip Evacuation

Solution: Adjust chip load (feed rate) and employ high-pressure coolant to clear swarf effectively.

Best Practices for Slow-Speed Milling Success

-

Choose the Right Tool Geometry:

- Opt for sharp, polished edges (reduces friction).

- Use variable helix end mills to dampen vibration.

-

Optimize Speeds and Feeds:

- Keep chip load consistent (e.g., 0.001–0.003 inches per tooth for aluminum).

- Reduce feed rates progressively in finishing passes.

-

Rigidity is Key:

- Shorten tool overhangs.

- Use tool holders with high clamping force (e.g., hydraulic or shrink-fit).

-

Coolant Strategy:

- Flood coolant for heat dissipation.

- Consider cryogenic cooling for exotic alloys.

-

Monitor Vibration and Acoustics:

- Use sensors to detect chatter early and adjust parameters.

Debunking the “Slow = Inefficient” Myth

While slow-speed milling trades speed for precision, it often reduces long-term costs by:

- Minimizing scrap from tool breakage.

- Eliminating secondary polishing/grinding.

- Slashing tooling expenses.

For mission-critical parts, “slow” can mean faster project completion when rework is avoided.

Conclusion: Slow-Speed Milling as a Strategic Advantage

Slow-speed milling isn’t a relic—it’s a proven technique for solving modern machining challenges. By mastering low-RPM strategies, manufacturers achieve repeatable precision, longer tool life, and flawless finishes on even the most demanding materials.

Key Takeaway: Integrate slow-speed milling into your process where quality outweighs speed, and pair it with smart tooling and setup choices. The result? Fewer errors, lower costs, and a reputation for unparalleled craftsmanship.

Ready to Optimize Your Milling Process?

Test slow-speed milling on your next high-stakes project. Start with conservative RPMs, monitor results, and fine-tune based on tool and material feedback. The rewards are worth the patience!

Tags: #SlowSpeedMilling, #CNCMachining, #PrecisionMachining, #ToolLife, #ManufacturingTips