Moving Floor Trailer

Title: Moving Floor Trailers: The Ultimate Solution for Efficient, Self-Loading Cargo Transport

Meta Description: Discover how moving floor trailers revolutionize cargo transport with self-loading systems, reducing labor costs and boosting efficiency. Learn key benefits, uses, and buying tips.

What is a Moving Floor Trailer?

A moving floor trailer (or “moving floor system”) is a specialized semi-trailer equipped with a hydraulic or electric-driven sliding floor. Unlike conventional trailers, the floor itself moves to load or unload bulk materials, loose goods, or uneven cargo—eliminating the need for manual labor, forklifts, or tipping mechanisms. This technology ensures faster operations, improved safety, and versatility across industries like waste management, agriculture, recycling, and logistics.

How Do Moving Floor Trailers Work?

The trailer’s floor consists of interlocking slats that slide back and forth via a motorized system. When activated:

- Loading: The moving floor pulls cargo inward.

- Unloading: The slats push cargo smoothly out of the trailer.

This “self-loading” mechanism handles diverse materials—from wood chips and grain to construction debris and municipal waste—without external equipment.

Key Features & Advantages

-

Durability & Strength

- Built with high-strength steel floors to withstand heavy, abrasive loads.

- Ideal for harsh environments (e.g., mining, recycling).

-

Self-Loading/Unloading

- Saves time and labor costs—operators unload 40-50 tons of material in minutes.

- No reliance on cranes or excavators, reducing onsite equipment needs.

-

Time Efficiency

- Faster turnaround times mean more trips per day.

-

Enhanced Safety

- Minimizes worker exposure to hazardous materials during manual unloading.

-

Low Maintenance

- Hydraulic systems require minimal upkeep compared to complex machinery.

Applications Across Industries

Moving floor trailers adapt to countless cargo types:

- Waste Management: Transporting municipal solid waste, recyclables, or biomass.

- Recycling Centers: Handling scrap metal, paper, or plastics.

- Agriculture: Moving grain, animal feed, or fertilizers.

- Construction: Transporting sand, gravel, or demolition waste.

- Logistics: Delivering bulky, non-palletized goods (e.g., tires, textiles).

5 Major Benefits of Using a Moving Floor Trailer

-

Cost Savings

- Reduce labor expenses and dependency on loading equipment.

- Lower fuel costs through optimized load distribution.

-

Enhanced Efficiency

- Unload cargo 3–5x faster than manual methods.

- Ideal for time-sensitive operations (e.g., perishable goods).

-

Versatility

- Customize trailers with multi-deck floors or adjustable lengths.

- Compatible with walking floors, push floors, or cable floor systems.

-

Environmental Impact

- Fewer machines on-site reduce noise pollution and carbon emissions.

-

All-Weather Reliability

- Perform consistently on rough terrain or in extreme temperatures.

Choosing the Right Moving Floor Trailer

Consider these factors before investing:

- Payload Capacity: Match trailer size (e.g., 40–65 feet) to your typical load volume.

- Material Type: Opt for reinforced floors for abrasive cargo like rocks or metal scraps.

- Floor System: Hydraulic systems suit heavy-duty use; electric systems offer quieter operation.

- Trailer Design: Options include flatbeds, curtain-siders, or enclosed boxes.

- Compliance: Ensure the trailer meets regional transport regulations (e.g., GVWR limits).

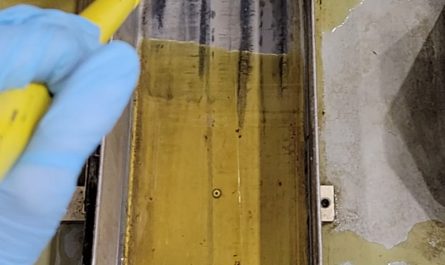

Maintenance Best Practices

- Regular Inspections: Check slats, hydraulics, and rollers for wear.

- Clean Thoroughly: Remove debris to prevent floor-jamming.

- Monitor Fluids: Maintain hydraulic oil levels to avoid system failure.

- Lubricate Components: Extend the life of moving parts with scheduled greasing.

- Operator Training: Ensure handlers understand loading limits and safety protocols.

Conclusion

Moving floor trailers are a game-changer for logistics efficiency, offering unmatched speed, safety, and versatility. By automating loading/unloading, businesses slash operational costs, reduce workplace risks, and maximize productivity. Whether you’re hauling waste, grain, or construction materials, this technology is a smart investment for any high-volume transport operation.

Upgrade your fleet today—embrace the future of cargo transport with moving floor trailers!

Keywords: Moving floor trailer, self-loading trailer, hydraulic floor system, waste management trailer, bulk cargo transport, low-maintenance trailer, cost-effective logistics, unloading efficiency, moving floor trailer benefits.