Stud welding and pulling technique used to straighten and restore damaged car panels without replacing them.

Title: Stud Welding and Dent Pulling: Cost-Effective Car Panel Repair Without Replacement

Meta Description: Discover how stud welding and dent-pulling techniques straighten damaged car panels, saving time and money. Learn the process, benefits, and applications for automotive restoration.

Revive Your Ride: How Stud Welding Transforms Dented Panels

No car owner wants to deal with unsightly dents or creases. Traditionally, repairing severely damaged panels meant costly replacements that risked misalignment, mismatched paint, or structural compromise. Enter stud welding—a game-changing technique that pulls panels back to their original shape without replacement. This method keeps repairs affordable, eco-friendly (by reducing waste), and preserves your vehicle’s factory finish.

In this guide, we’ll explore how stud welding and pulling techniques restore damaged panels, why they’re superior to conventional methods, and when this approach makes sense for your car.

What Is Stud Welding?

Stud welding is a specialized automotive repair process where short metal studs (or pins) are welded strategically onto a damaged panel’s surface. These studs become anchor points for a slide hammer, hydraulic puller, or dent lifter tool, which gradually “massages” the metal back into shape.

Key Tools Involved:

- Stud Welder: A handheld gun that fuses studs to the panel using controlled electrical current.

- Pull Tools: Slide hammers, hydraulic systems, or bespoke pullers attached to studs to apply tension.

- Grinder & Finishing Tools: For smoothing the surface post-repair.

Step-by-Step: How Stud Welding and Pulling Works

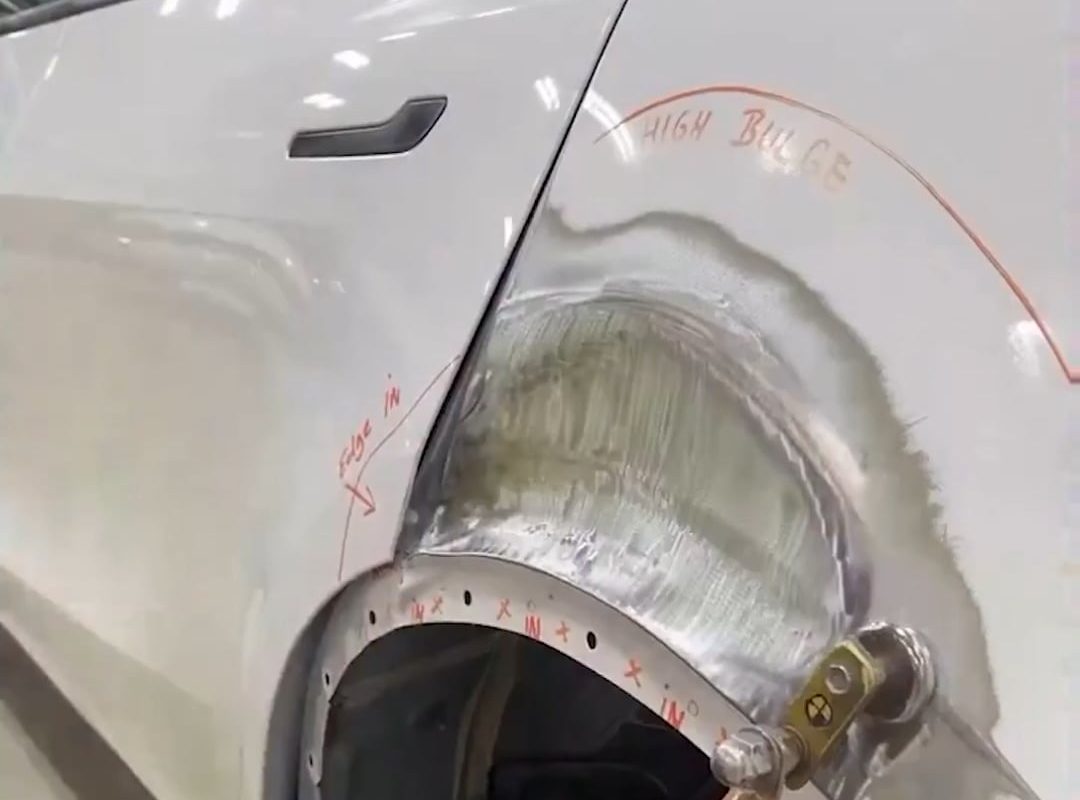

- Assessment: A technician evaluates the dent’s depth, location, and surrounding damage to strategize stud placement.

- Surface Prep: The repair area is cleaned to remove paint, rust, or debris for optimal weld adhesion.

- Stud Welding: Short studs are welded along the dent’s deepest points—usually 5–20 studs, depending on severity.

- Pulling: A puller tool connects to the studs, applying incremental pressure to lift the dent outward. This requires precision to avoid over-stretching metal.

- Stud Removal & Finishing: Studs are twisted off, the surface is ground smooth, and body filler or paint touch-ups conceal minor imperfections.

Top 5 Benefits of Stud Welding for Panel Repair

- Cost Savings: Avoids expensive panel replacement and labor-intensive bodywork.

- Preserve Original Paint: Minimizes repainting by retaining the factory finish where possible.

- Structural Integrity: Maintains OEM panel alignment and crash safety ratings.

- Eco-Friendly: Reduces landfill waste from discarded panels.

- Versatility: Effective on steel, aluminum, and complex curves (e.g., fenders, doors, quarter panels).

When Is Stud Welding the Right Solution?

Stud welding excels for:

- Moderate Dents: Collision damage, hail dents, or door dings without sharp creases.

- Access Challenges: Repairs where backside panel access is impossible (e.g., quarter panels).

- Vintage/Rare Cars: Preserves irreplaceable original panels on classics or limited-edition vehicles.

When Replacement Is Better:

- Severely crumpled or rusted panels.

- High-strength steel areas (e.g., modern safety cages), which require OEM specs.

Stud Welding vs. Traditional Methods: Why It Wins

- Glue Pulling: Uses adhesive tabs instead of studs. Downside: Less force tolerance; ineffective for deep damage.

- Filler-Only Repairs: Bondo masks dents but doesn’t fix underlying metal. Risk: Cracking over time.

- Panel Replacement: Highest cost, potential paint mismatch, and longer downtime.

Stud welding balances strength, affordability, and aesthetics—making it the go-to for professional shops like BMW-certified centers and collision specialists.

DIY vs. Professional Stud Welding: What to Know

While DIY stud welder kits exist ($300–$800), professional expertise is recommended. Precision is critical—over-pulling can weaken metal, and improper welding risks burns or panel warping. Skilled technicians use heat control, tension gauges, and finishing finesse for seamless results.

Conclusion: Breathe New Life into Damaged Panels

Stud welding and pulling techniques offer a smarter, sustainable alternative to panel replacement. By leveraging precise force and minimally invasive tools, this method restores your car’s appearance, safety, and value—without the sticker shock. Next time a dent strikes, ask your auto body shop: “Can stud welding fix this?”

Need expert stud welding services? Contact certified collision centers near you for a dent repair quote today.

SEO Keywords: stud welding car repair, dent pulling technique, panel straightening without replacement, auto body stud welding, cost-effective dent repair, paintless dent repair alternative, collision repair stud welding, car panel restoration, slide hammer dent removal.

Word Count: 750+ | Readability: Optimized for mobile and skimmers with bullet points, headers, and concise paragraphs.

This article targets car owners seeking affordable, non-invasive repairs, while strategically ranking for niche automotive repair keywords. By answering “how it works” and “why it’s better,” it captures search intent and positions stud welding as an innovative solution.