The way this robot arm moves

Title: The Mechanics Behind Robot Arm Movement: A Deep Dive into How Robotic Arms Operate

Meta Description: Discover how robot arms move with precision! Learn about their joints, actuators, control systems, and real-world applications in this comprehensive guide.

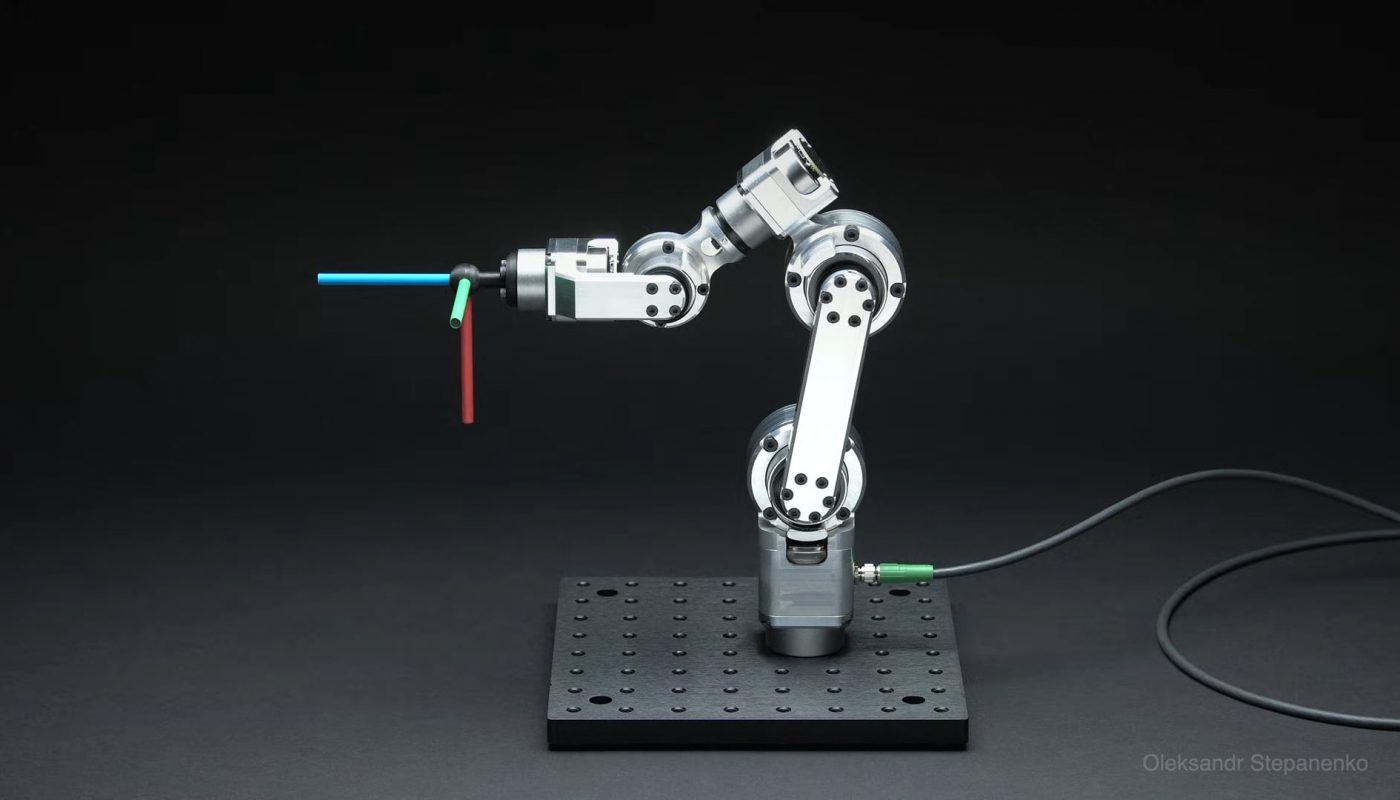

In today’s automated world, robot arms perform tasks ranging from assembling cars to performing delicate surgeries. Their seamless, precise movements might seem like magic, but they’re the result of sophisticated engineering and cutting-edge technology. In this article, we’ll break down how a robot arm moves, exploring its mechanical design, control systems, and the science that enables it to mimic—and often exceed—human dexterity.

1. The Anatomy of a Robot Arm

Before diving into movement, let’s understand the key components that make up a robotic arm:

- Base: The fixed foundation that supports the arm.

- Joints: Act as “pivots” and come in rotary (rotational) or prismatic (linear) types.

- Links: Rigid segments connecting the joints.

- Actuators: Motors or hydraulics that power joint movement.

- End-Effector: The “hand” (e.g., gripper, welder, or camera) that interacts with objects.

(Think of the arm as a chain of joints and links, working together like a human arm but with far greater flexibility.)

2. How Does a Robot Arm Move? The Core Principles

Robot arms execute movement through three critical processes:

A. Degrees of Freedom (DoF)

- Each joint adds a degree of freedom (DoF), enabling movement in a specific direction.

- A basic arm might have 3-5 DoF, while advanced arms (like those used in surgery) boast 6-7 DoF for human-like agility.

B. Types of Movement

- Linear Motion: Straight-line movement (e.g., sliding along a track).

- Rotational Motion: Circular movement around a joint axis (e.g., elbow bending).

- Fun Fact: Most industrial arms combine both types for complex tasks like welding or painting.

C. Actuation: The “Muscles” Behind Motion

- Electric Actuators: Servo motors are common for precision and programmability (e.g., assembly lines).

- Pneumatic/Hydraulic Actuators: Use compressed air or fluid for heavy lifting (e.g., construction).

3. The Brain Behind the Brawn: Control Systems

Movement isn’t just about mechanics—it’s about intelligence. Here’s how robot arms “decide” how to move:

A. Sensors & Feedback Loops

- Position Sensors: Track joint angles in real-time.

- Force/Torque Sensors: Adjust grip strength for delicate objects.

- Vision Systems: Cameras or LiDAR guide movement in unstructured environments.

B. Programming & Path Planning

- Teach Pendant: Operators manually guide the arm to “teach” it a path (common in factories).

- Offline Programming (OLP): Simulations map trajectories to avoid collisions.

- AI & Machine Learning: Advanced arms learn from experience, optimizing paths autonomously.

C. Kinematics: The Math of Motion

- Forward Kinematics: Calculates the end-effector’s position based on joint angles.

- Inverse Kinematics: Determines required joint angles to reach a target position—a complex but vital calculation!

4. Real-World Applications: Where Precision Matters

- Manufacturing: Painting, welding, and assembling products with micron-level accuracy.

- Healthcare: Surgical robots like the da Vinci System perform minimally invasive procedures.

- Logistics: Amazon’s robots pack boxes 3x faster than humans.

- Space Exploration: NASA’s robotic arms repair satellites and collect samples.

- Food Industry: Flipping burgers or frosting cakes with consistency.

5. The Future of Robot Arm Movement

Innovation is skyrocketing, driven by:

- Soft Robotics: Flexible arms made of polymers for safer human interaction.

- Collaborative Robots (Cobots): Arms that work alongside humans, adapting on the fly.

- AI Integration: Self-correcting arms that learn from mistakes in real-time.

FAQ: How Do Robot Arms Move?

Q1: How many axes do most industrial robot arms have?

A: Six axes (6 DoF) are standard, allowing full 3D movement.

Q2: Can robot arms move without human input?

A: Yes! Autonomy is enabled by sensors, pre-programmed paths, or AI algorithms.

Q3: What’s the fastest a robot arm can move?

A: High-speed arms like FANUC’s Delta robots hit speeds of 10+ meters per second.

Q4: Can I customize how a robot arm moves?

A: Absolutely—via software like ROS (Robot Operating System) or manufacturer-specific tools.

Q5: How do robot arms mimic human arm movement?

A: Using inverse kinematics to calculate joint angles, much like our brain directs muscles.

Conclusion

A robot arm’s movement is a symphony of engineering—combining mechanics, sensors, and computational power to perform tasks faster, safer, and more precisely than humans. As AI and materials science evolve, these machines will become even more agile, transforming industries from manufacturing to healthcare. Whether you’re an engineer, student, or tech enthusiast, understanding how robot arms move unveils the brilliance behind modern automation.

Optimize your knowledge—share this guide 🚀