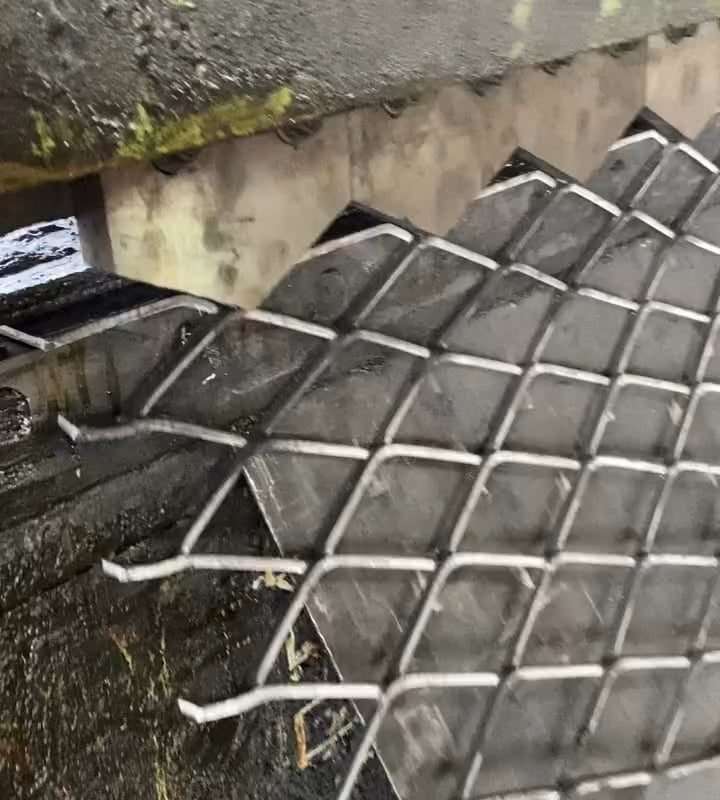

This is how a net fence is made

Meta Title: How Net Fencing is Made: Materials, Process & Applications | Complete Guide

Meta Description: Discover how net fences are manufactured, from raw materials to finished product. Learn about materials, weaving techniques, quality control, and applications.

How Net Fencing Is Made: A Step-by-Step Guide to Manufacturing Process

Net fencing is a versatile and cost-effective solution for agriculture, sports fields, construction sites, and residential security. But have you ever wondered how these durable wire nets are made? In this article, we break down the manufacturing process, materials, and quality checks that go into crafting a reliable net fence.

What is Net Fencing?

Net fencing consists of interlinked wires woven into a grid-like pattern. It comes in various sizes, strengths, and materials to suit different needs (e.g., chain-link, welded wire mesh, or hexagonal poultry netting). Its durability, flexibility, and ease of installation make it ideal for boundary marking, animal enclosures, and safety barriers.

The Materials Used in Net Fence Production

1. Wire Selection

- Galvanized Steel Wire: Rust-resistant and long-lasting due to a zinc coating.

- PVC-Coated Wire: Adds extra weather resistance and color options (e.g., green or black).

- Stainless Steel: Used in high-corrosion environments like coastal areas.

- Aluminum: Lightweight option for temporary fencing.

2. Coating Materials

- Zinc Galvanization: Applied via hot-dipping or electrochemical processes to prevent rust.

- PVC (Polyvinyl Chloride): Melted and bonded to wires for enhanced durability.

Step-by-Step Manufacturing Process

Step 1: Wire Drawing

Raw steel rods are pulled through progressively smaller dies to reduce thickness and achieve the desired gauge (e.g., 1.5mm–3mm). This also strengthens the wire through work hardening.

Step 2: Galvanization (Corrosion Protection)

Wires are submerged in molten zinc (hot-dip galvanizing) or coated electrolytically. This creates a protective layer that extends the fence’s lifespan by 20–30 years.

Step 3: Weaving/Forming the Mesh

- Automatic Weaving Machines: Wires are fed into high-speed looms that interlock them into patterns:

- Chain Link: Wires are twisted into zig-zag diamond shapes.

- Welded Mesh: Wires are laid perpendicularly and fused at intersections via electric welding.

- Hexagonal Netting (Chicken Wire): Wires are woven into six-sided honeycomb patterns.

Step 4: PVC Coating (Optional)

Galvanized wires are passed through an extruder, where liquid PVC is applied and cured in an oven. This layer adds UV resistance and aesthetic appeal.

Step 5: Cutting and Rolling

Finished mesh is trimmed to standard sizes (e.g., 50m rolls) or custom dimensions. Edges are sealed or knotted to prevent fraying.

Step 6: Quality Control

- Tensile Strength Tests: Ensures wires withstand pulling forces.

- Salt Spray Tests: Validates corrosion resistance.

- Mesh Uniformity Checks: Confirms consistent grid sizing.

Key Applications of Net Fences

- Agriculture & Livestock: Protects crops and contains poultry or livestock (e.g., chicken wire).

- Sports Facilities: Ball stop nets for golf ranges or soccer fields.

- Safety Barriers: Safeguards construction sites or highways.

- Residential Use: Garden fencing, trellises, or pet enclosures.

Why Choose Net Fencing?

- Affordable: Lower cost than wood or vinyl fencing.

- Low Maintenance: Resists rot, pests, and weather damage.

- Quick Installation: Lightweight and easy to mount with posts and clips.

- Eco-Friendly: Recyclable materials like steel reduce environmental impact.

Final Thoughts

Net fencing combines simplicity with robust engineering. From wire drawing to galvanization and weaving, manufacturers prioritize durability and adaptability to create fences that meet diverse needs. Whether you’re securing a farm or building a playground, understanding how net fences are made helps you choose the right product for long-term performance.

Pro Tip: For maximum longevity, opt for PVC-coated galvanized wire fencing in humid or coastal regions!

SEO Keywords: net fence manufacturing process, how wire netting is made, chain link fence production, galvanized wire fencing, PVC-coated net fence, welded mesh manufacturing, hexagonal net fencing, agricultural fencing guide.

By explaining the technical process in an easy-to-understand format, this article targets readers seeking practical insights while optimizing for SEO through keyword integration, headings, and structured content.