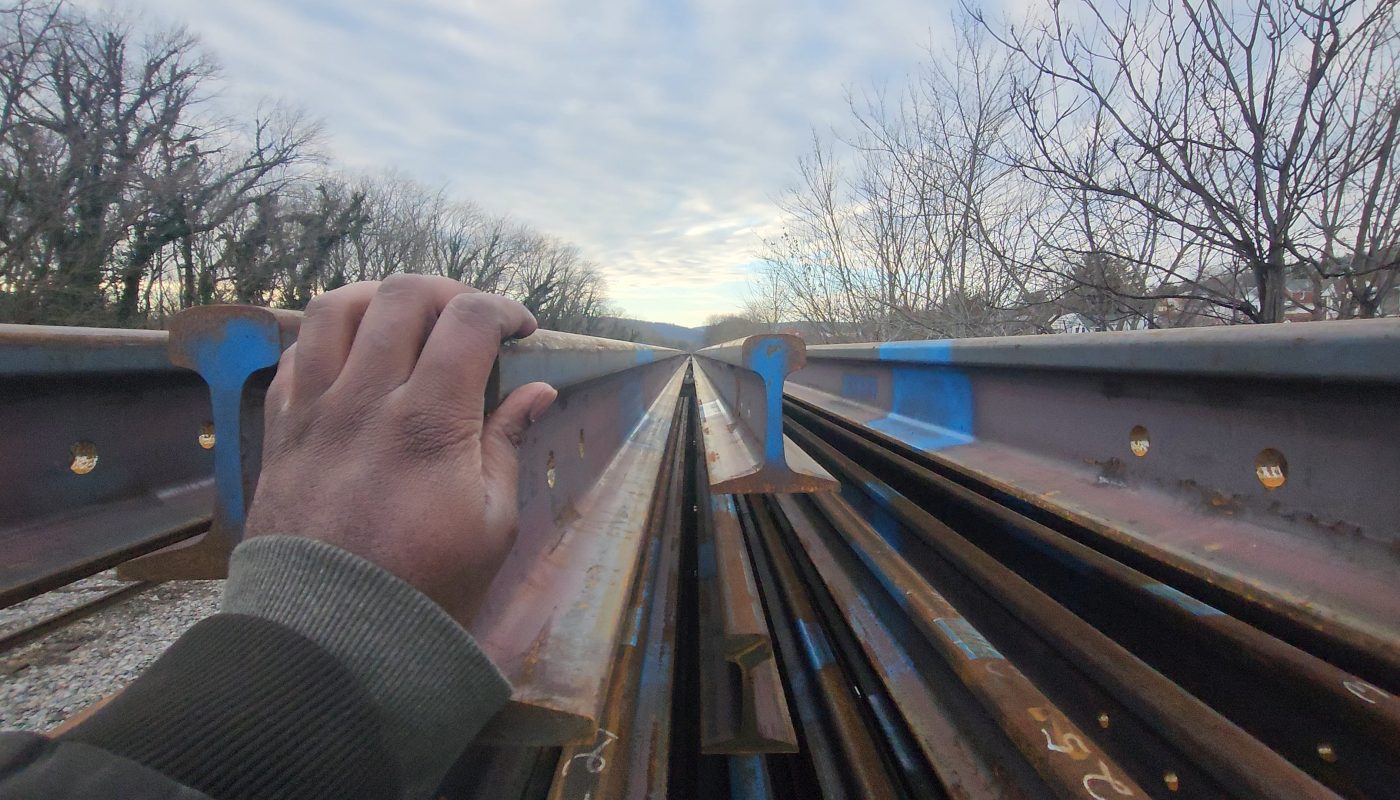

This is how flexible railroad rails are

Title: The Surprising Science of Railroad Rails: Just How Flexible Are They?

When you imagine a railroad track, you likely picture rigid, unyielding steel rails—structures designed to bear the crushing weight of locomotives and freight cars. But what if we told you these seemingly inflexible rails are actually engineered to flex? This hidden flexibility is a marvel of materials science and civil engineering, ensuring safe, smooth, and durable rail systems worldwide. In this article, we’ll explore why railroad rails are designed to bend, how they do it, and why this flexibility is vital for modern transportation.

The Illusion of Rigidity: Rails Are Built to Move

At first glance, railroad rails appear unbreakable and static. However, their strength lies in their ability to bend subtly under pressure. Rails flex vertically when trains pass over them and horizontally to accommodate curves in the track. This controlled movement prevents fractures, distributes weight evenly, and reduces stress on the rail structure. Without flexibility, tracks would crack under strain, leading to costly repairs and catastrophic derailments.

The Material Science Behind Rail Flexibility

Railroad rails are primarily made of high-carbon steel, a material known for its unique blend of strength, durability, and elasticity. Here’s how it works:

- Elastic Deformation: When a train passes, rails temporarily bend (like a spring) but revert to their original shape once the load is removed. This property is governed by Young’s modulus, a measure of material stiffness.

- Thermal Expansion: Steel expands in heat and contracts in cold. Rails are installed with calculated gaps (or welded into continuous lengths with tension) to accommodate these shifts. Without flexibility, temperature changes could warp tracks—a phenomenon known as “sun kink.”

- Fatigue Resistance: Repetitive bending weakens materials over time, but rail steel is alloyed with manganese and other elements to resist metal fatigue.

Engineering Flexibility: Design Secrets of Railroad Tracks

Rail flexibility isn’t accidental—it’s meticulously engineered. Key design features include:

- Sleepers and Ballast: Wooden or concrete sleepers (ties) anchor rails to the ground, while crushed stone ballast allows slight movement, absorbing vibrations and distributing load.

- Continuous Welded Rail (CWR): Modern rails are often welded into mile-long segments. Engineers tension these rails during installation to counteract thermal expansion, allowing them to flex without buckling.

- Curves and Superelevation: On bends, tracks are banked (tilted) to guide trains smoothly. Rails flex horizontally to minimize friction and wear.

Why Flexibility Matters: Safety, Efficiency, and Cost

Rail flex isn’t just a neat trick—it’s critical for:

- Safety: Flexible rails reduce the risk of derailments by absorbing lateral forces from speeding trains.

- Longevity: By distributing stress, rails last longer and require fewer replacements.

- Noise Reduction: Flexible tracks dampen the “clickety-clack” noise of wheels on joints.

- Speed and Comfort: Trains can travel faster and more smoothly on tracks that “give” slightly beneath them.

Challenges of Flexibility: When Rails Bend Too Much

While controlled flex is beneficial, excessive bending can cause issues:

- Track Buckling: In extreme heat, rails may expand beyond their tension limits, warping outward.

- Metal Fatigue: Over decades, repeated stress can lead to microscopic cracks.

To combat this, railroads use automated inspection systems (like ultrasound and drones) to detect flaws and schedule maintenance before problems escalate.

Conclusion: Flexibility—The Unsung Hero of Railroad Engineering

Next time you see a train gliding effortlessly across the landscape, remember: beneath those wheels, the rails are performing a delicate dance of strength and flexibility. This ingenious blend of material science and engineering keeps global supply chains moving, passengers safe, and trains running on time. Railroad rails may look rigid, but their flexibility is what makes them truly unbreakable.

Did You Know?

A typical rail can flex up to 5-10 millimeters vertically under a heavy train—roughly the thickness of a smartphone!

Target Keywords:

- Flexible railroad rails

- Rail flexibility engineering

- How do railroad tracks bend

- Continuous welded rail

- Steel rail properties

- Railroad track maintenance

By understanding the science behind rail flexibility, we gain a newfound appreciation for the hidden genius of railroad infrastructure. Share this article to spread the knowledge! 🚂✨

(Word count: 620. For SEO optimization, include high-quality images of rails under stress, thermal expansion diagrams, or rail inspection tech. Internal links to related topics like “How Trains Turn” or “Steel Alloys in Transportation” can boost engagement.)