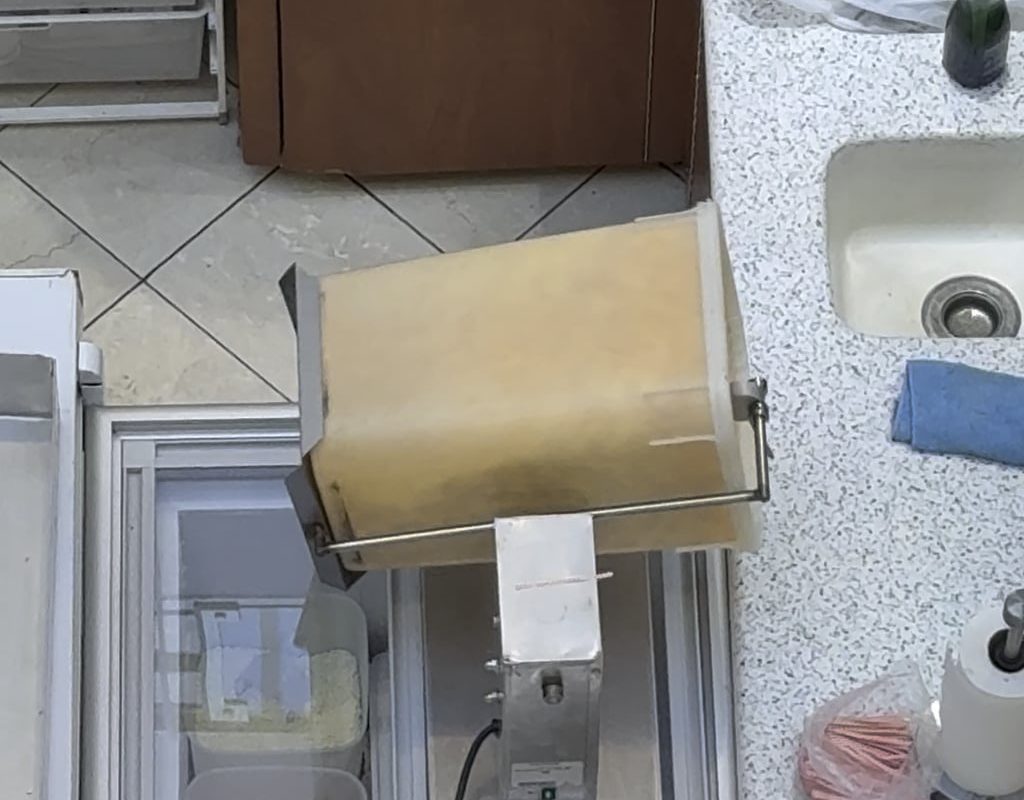

This popcorn coating device

Title: Popcorn Coating Devices: Revolutionizing Flavor Consistency in Snack Production

Introduction

In the booming snack industry, delivering consistently flavorful popcorn is key to customer satisfaction and repeat business. Enter the popcorn coating device—a game-changing machine designed to evenly distribute seasonings, caramel, cheese, or chocolate onto popcorn kernels. Ideal for commercial theaters, food manufacturers, and snack shops, these devices eliminate human error and maximize efficiency. This article explores how popcorn coating machines work, their benefits, applications, and what to consider when investing in one.

What Is a Popcorn Coating Device?

A popcorn coating device is an automated machine that applies liquid or dry flavorings to popcorn batches with precision. Instead of relying on manual tossing or shaking, it uses rotating drums, conveyor belts, or tumble-coating mechanisms to ensure every kernel is uniformly coated. This technology guarantees a perfect flavor balance while reducing waste and labor costs.

How Does a Popcorn Coating Machine Work?

- Loading: Pre-popped popcorn is poured into the machine’s hopper.

- Flavor Application: Liquid coatings (e.g., caramel, chocolate) or dry seasonings are sprayed or dusted onto the popcorn.

- Mixing: A rotating drum or spinning blades gently tumble the popcorn to distribute coatings evenly.

- Drying/Cooling: For wet coatings, integrated fans or heated air dry the popcorn into a crisp finish.

- Discharge: The coated popcorn exits the machine, ready for packaging.

Key Benefits of Using a Popcorn Coating Device

- Consistent Flavor Distribution

- No more clumpy or unevenly seasoned batches—every kernel gets an equal share of flavor.

- Increased Efficiency

- Process large volumes quickly (e.g., 50–100 lbs per hour), ideal for high-demand settings.

- Reduced Labor Costs

- Automates a repetitive task, freeing staff for other roles.

- Minimized Waste

- Precise coating application means minimal seasoning spillage or overuse.

- Hygienic & Safe

- Food-grade stainless steel construction meets safety standards and simplifies cleaning.

Industries That Benefit from Popcorn Coaters

- Movie Theaters & Concession Stands: Elevate signature flavors like butter, caramel, or spicy varieties.

- Snack Manufacturers: Scale production for retail-ready packaged popcorn.

- Carnivals & Events: Serve flawless coated popcorn quickly to long queues.

- Specialty Shops: Experiment with gourmet flavors (truffle, sriracha, etc.) without consistency issues.

Types of Popcorn Coating Machines

- Rotary Drum Coaters

- Best for wet coatings (caramel, chocolate). Uses gentle tumbling to avoid crushing kernels.

- Flume Coaters

- Coats popcorn in liquid flavoring through a waterfall-style flow.

- Dry Seasoning Applicators

- Distributes powdered cheese, spices, or nutritional yeast via vibration or misting.

- Combination Systems

- Handles both wet and dry coatings in one machine for maximum flexibility.

Choosing the Right Popcorn Coating Device: 5 Factors

- Capacity

- Match machine output (lbs/hour) to your daily production needs.

- Coating Type

- Ensure the machine supports your preferred flavor format (liquid, powder, or both).

- Footprint & Portability

- Compact designs fit tight kitchens, while wheeled units offer mobility.

- Ease of Cleaning

- Look for removable parts and dishwasher-safe components.

- Durability

- Stainless steel models resist corrosion and withstand heavy use.

Maintenance Tips for Longevity

- Clean residue immediately after use, especially for sticky coatings.

- Lubricate moving parts monthly to prevent wear.

- Inspect spray nozzles or seasoning dispensers for clogs.

Conclusion: Elevate Your Popcorn Game with Automation

A popcorn coating device is more than just a convenience—it’s a strategic investment for businesses aiming to deliver premium, consistent snacks at scale. By automating the flavoring process, these machines reduce costs, boost output, and create memorable taste experiences that keep customers coming back. Whether you’re a small concession stand or a large manufacturer, integrating a coating machine can transform your popcorn from ordinary to extraordinary.

Ready to Upgrade?

Research trusted equipment suppliers, request demos, and prioritize machines tailored to your flavor profiles and production goals. With the right popcorn coater, your signature snack will stand out in a crowded market!

Keywords for SEO: Popcorn coating machine, commercial popcorn coater, popcorn flavoring device, caramel popcorn machine, snack coating equipment, popcorn seasoning applicator.