Train Crash Test

Title: Train Crash Testing: Engineering Safety on the Rails with Controlled Chaos

Meta Description: Discover how train crash tests revolutionize rail safety. Learn about methodologies, real-world examples, and the future of collision testing in this in-depth guide.

Introduction

In an era where millions rely on trains daily for commuting and freight, safety remains paramount. Train accidents—though rare—can be catastrophic, making train crash testing a critical pillar of modern rail engineering. These controlled collision experiments are not about destruction; they’re about innovation, helping engineers design safer, more resilient trains that protect lives even in worst-case scenarios.

This article explores the science, technology, and impact of train crash tests, revealing how these simulations shape the future of rail travel.

What is a Train Crash Test?

A train crash test is a meticulously planned experiment where trains or carriages are deliberately collided to study impact dynamics, structural integrity, and passenger safety mechanisms. Unlike automotive crash tests, train collisions involve vastly higher mass and energy, requiring specialized facilities and advanced instrumentation.

Key Goals of Crash Testing:

- Evaluate Safety Systems: Test crumple zones, anti-climbing devices, and seat integrity.

- Validate Computer Models: Confirm simulations of collision physics.

- Compliance with Standards: Meet strict regulations (e.g., EN 15227 in Europe, FRA rules in the U.S.).

Why Train Crash Testing Matters

Rail accidents often involve complex factors like speed, weight, and terrain. Crash tests provide invaluable insights:

- Passenger Survival: Optimizing coach design to minimize injury during derailments or collisions.

- Infrastructure Protection: Reducing damage to tracks, signals, and stations.

- Freight Safety: Ensuring hazardous materials remain contained.

A 2022 UIC report found that crashworthiness improvements (informed by testing) reduced collision fatalities by 35% over the past decade.

The Science Behind the Impact: How Tests Work

Methodologies

-

Full-Scale Crash Tests:

- Real trains collide at controlled speeds (e.g., 50–100 km/h).

- Example: The 2015 German Rail (DB) test featured two trains colliding head-on at 100 km/h to test new coupling systems.

-

Component Testing:

- Isolated experiments on buffers, bogies, or energy-absorbing materials.

-

Computer Simulations (Virtual Testing):

- Finite Element Analysis (FEA) predicts deformation and stress using digital twins.

Data Collection

- High-Speed Cameras: Capture microsecond-level deformation.

- Accelerometers: Track G-forces on dummies.

- Crash Recorders: Log data similar to aviation’s “black boxes.”

Key Components Tested in Collisions

- Crumple Zones: Designed to absorb kinetic energy while keeping passenger cabins intact.

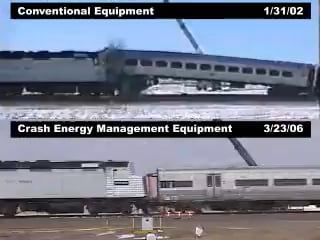

- Anti-Climbing Mechanisms: Prevent telescoping (one car riding over another).

- Fire Resistance: Materials tested for flammability and toxic emissions.

Case Study: In 2019, the European Union’s SAFRAIL project used crash tests to refine composite materials that reduced post-crash fires by 60%.

Notable Train Crash Test Examples

- The “Miracle Train” (Japan, 1996): After a fatal crash, Japan’s RTRI developed crash-energy-absorbing nose designs now standard in Shinkansen bullet trains.

- CERTAC (France): Europe’s largest crash test facility simulates collisions up to 225 kJ impact energy.

- TTCI (USA): Conducts derailment testing to improve tank car safety for crude oil transport.

Challenges in Modern Crash Testing

- Cost: Full-scale tests can exceed $2 million due to logistics and equipment.

- Scalability: Results from light-rail tests may not apply to heavy freight trains.

- Multiphysics Complexity: Balancing structural safety with ergonomic and electrical systems.

The Future: Innovation in Rail Safety

- AI-Powered Simulations: Machine learning predicts crash outcomes faster than FEA.

- Adaptive Materials: Self-healing composites or shape-memory alloys for real-time damage control.

- Global Collaboration: Shared databases like ERA’s rail accident archive standardize safety protocols worldwide.

Conclusion

Train crash tests epitomize the marriage of controlled chaos and cutting-edge engineering. Every collision staged in a test facility translates to lives saved on actual railways. As technology advances, these tests will continue to push boundaries—ensuring that even at high speeds, safety remains firmly on track.

FAQs

Q: How often are train crash tests conducted?

A: Full-scale tests are rare (often years apart) due to cost, but virtual tests occur daily.

Q: Do drones play a role in crash analysis?

A: Yes! Drones capture aerial footage of wreckage patterns for 3D modeling.

Q: Can crash tests prevent all rail accidents?

A: No—but they drastically reduce risks, especially in collisions and derailments.

Q: Are maglev trains crash-tested?

A: Yes. Japan’s SCMaglev undergoes rigorous collision simulations despite lacking wheels.

Keywords for SEO: Train crash test, rail safety testing, train collision experiment, railway crashworthiness, rail impact test, EN 15227, train safety systems.

Optimize your rail safety knowledge today—share this article to spread awareness! 🚄🛤️