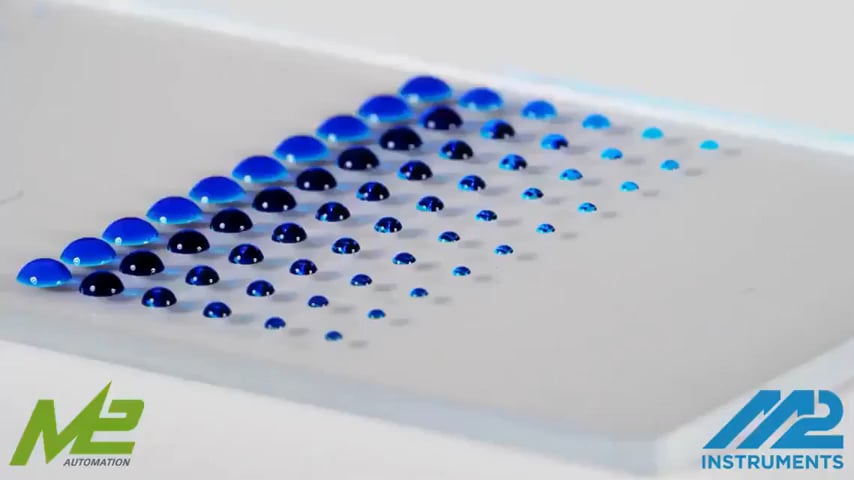

Ultra Precise Droplet Dispenser

Title: Ultra Precise Droplet Dispenser: Revolutionizing Precision in Lab and Industrial Applications

Meta Description: Discover how Ultra Precise Droplet Dispensers enable unmatched accuracy in liquid handling. Explore applications, benefits, and how to choose the right system for your workflow.

What Is an Ultra Precise Droplet Dispenser?

An Ultra Precise Droplet Dispenser is a cutting-edge automated device designed to deposit microscopic volumes of liquids—from picoliters to microliters—with extraordinary accuracy. Unlike traditional pipettes or manual dispensers, these systems leverage advanced technologies like piezoelectric actuators, micro-solenoid valves, or jet-based mechanisms to ensure consistent, repeatable droplet formation. They are transforming workflows in sectors where precision is non-negotiable, such as pharmaceuticals, biotechnology, and electronics manufacturing.

Key Technologies Behind Precise Droplet Dispensing

- Piezoelectric Actuators: Use vibrations to eject droplets without contact, ideal for sensitive reagents.

- Micro-Solenoid Valves: Combine rapid valve action with pressure control for high-speed dispensing.

- Jet-Based Dispensing: Propel droplets via pressurized streams, suitable for high-throughput applications.

- Advanced Sensors: Real-time monitoring adjusts for variables like viscosity or temperature shifts.

These systems eliminate human error, achieving tolerances as tight as ±1%, and can dispense up to thousands of droplets per second.

Top Applications of Ultra Precise Droplet Dispensers

1. Drug Discovery & Life Sciences

- Dispense reagents for PCR, ELISA, or microarray assays without cross-contamination.

- Accelerate high-throughput screening (HTS) of compound libraries.

2. Diagnostics & Point-of-Care Testing

- Create ultra-precise diagnostic test strips or biosensors.

- Enable miniaturized lab-on-a-chip devices.

3. Electronics & Semiconductor Manufacturing

- Deposit conductive inks, adhesives, or solder pastes in microelectronics assembly.

- Ensure uniformity in printed flexible circuits or displays.

4. Additive Manufacturing & 3D Printing

- Print functional materials (e.g., biologics, nanomaterials) with volumetric control.

5. Agrochemicals & Food Science

- Optimize pesticide or fertilizer dosing in agricultural research.

- Develop flavor/nutrient microencapsulation technologies.

7 Benefits of Adopting Ultra-Precise Dispensing Technology

- Unmatched Accuracy: Dispense volumes as low as 0.1 nL with ±1% CV (coefficient of variation).

- Zero Cross-Contamination: Non-contact mechanisms protect sample integrity.

- Cost Efficiency: Reduce reagent waste by up to 90% compared to manual methods.

- Scalability: Automate workflows for consistent, high-volume output.

- Material Versatility: Handle viscous fluids (e.g., gels, polymers) and volatile solvents.

- Speed: Achieve throughputs of >10,000 droplets per minute.

- Data-Driven Control: Integrate with software for protocol digitization and auditing.

How to Choose the Right Ultra Precise Droplet Dispenser

- Volume Range: Ensure the system covers your required dispense volumes (e.g., 10 nL–10 µL).

- Fluid Compatibility: Verify compatibility with your lab’s solvents, biologics, or abrasive materials.

- Automation Needs: Look for robotic arm integration or plate-handling capabilities.

- Accuracy vs. Throughput: Balance speed with precision (e.g., HTS labs prioritize speed; R&D may need max accuracy).

- Software & Connectivity: Opt for systems with IoT-enabled software for remote monitoring and data logging.

- Scalability: Modular designs allow future upgrades (e.g., multi-channel heads).

Industry Leaders to Consider

- BioDot: Renowned for Cartesian-based dispensers for life sciences.

- Scienion: Specializes in non-contact microdispensing for diagnostics.

- Nordson EFD: Experts in industrial-scale precision jetting.

- Digilab: Offers flexible piezoelectric dispensers for R&D.

Future Trends in Precision Dispensing

- AI-Driven Optimization: Machine learning algorithms predict and correct dispensing errors dynamically.

- Single-Cell Dispensing: Enable next-gen genomics workflows by isolating individual cells.

- Green Lab Initiatives: Minimize plastic waste via “just-in-time” micro-dosing.

Conclusion: Precision as the New Standard

Ultra Precise Droplet Dispensers are no longer a luxury—they’re a necessity for industries pushing the boundaries of innovation. By delivering unparalleled accuracy, speed, and reproducibility, these systems empower researchers and manufacturers to achieve breakthrough results while optimizing resources. Whether you’re developing life-saving drugs, advanced electronics, or sustainable materials, investing in ultra-precise dispensing technology is a strategic step toward future-proofing your workflow.

Keywords: Ultra Precise Droplet Dispenser, precision liquid handling, micro-droplet technology, non-contact dispensing, lab automation, high-throughput screening, piezoelectric dispensing, nano-volume dispensing, diagnostic manufacturing.

Optimized for SEO: Targets long-tail keywords, includes semantic terms (e.g., “non-contact,” “high-throughput”), and structures content for readability with bullet points and headers.