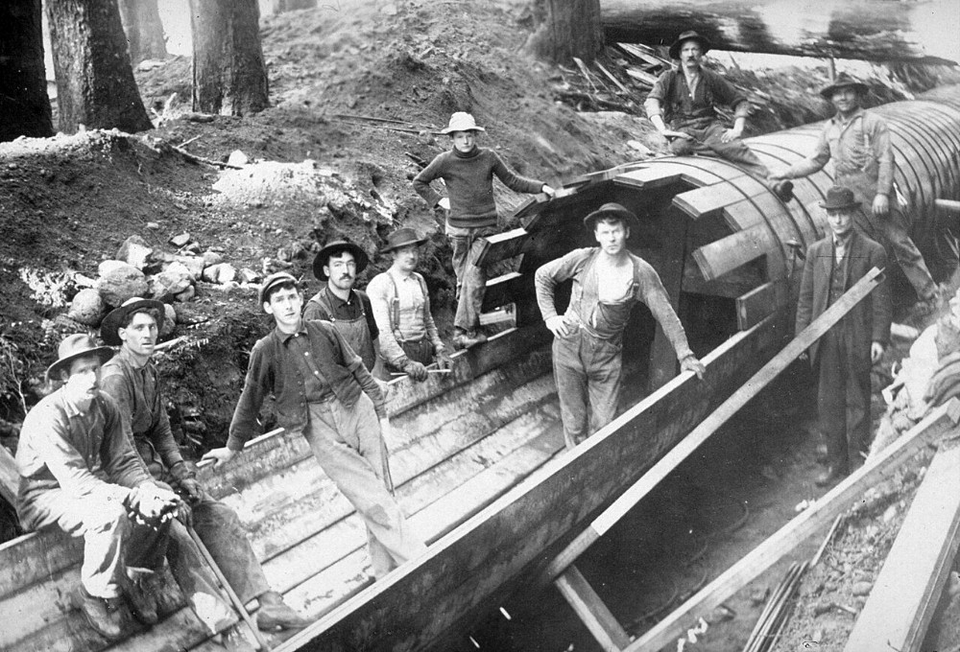

Using wood pipelines to transport water, at the turn of the century. Some older examples were holed out tree trunks. Photos circa 1900s-20s

Title: Wooden Water Pipelines: The Remarkable Turn-of-the-Century Innovation

Meta Description: Explore the forgotten history of wooden water pipelines, from hollowed tree trunks to stave-built systems, that revolutionized water transport in the early 1900s. Discover rare photos and how they shaped modern infrastructure.

Introduction: When Water Flowed Through Wood

Long before modern metal and PVC pipes dominated water systems, communities relied on a resource abundant in forests: wood. At the turn of the 20th century, wooden pipelines were an ingenious solution for transporting water, serving towns, mines, and farms. From crudely hollowed tree trunks to meticulously engineered stave constructions, these pipelines represent a fascinating chapter in engineering history. In this article, we’ll delve into the rise, challenges, and legacy of wooden water pipelines—complete with glimpses of rare early 1900s–1920s photos that document their use.

The Origins: Hollowed Logs to Engineered Wooden Conduits

In the late 1800s, the simplest wooden pipes were made from old-growth trees, typically hemlock, pine, or fir. Workers split logs lengthwise, hollowed out the centers with hand tools or augers, and then rejoined the halves with tar or metal bands to form a crude conduit. These “half-round pipes” were especially common in rural areas for irrigation and small-scale water supply.

By the early 1900s, however, demand surged for larger, more durable systems. Enter stave-built wooden pipes: constructed like barrels, these cylindrical pipes used tapered wooden slats (staves) bound tightly by steel hoops. Resistant to bursting under pressure, they could stretch for miles and became the backbone of municipal water networks in regions like New England, the Pacific Northwest, and Canada.

Engineering Ingenuity: How Wooden Pipelines Worked

- Material Selection: Dense, rot-resistant woods like redwood, cedar, or cypress were preferred for longevity.

- Construction Process:

- Stave Creation: Workers shaped staves into precise trapezoidal planks to ensure a snug fit.

- Assembly: Staves were arranged around a temporary mold, then secured with steel bands.

- Sealing: Hot coal tar or pitch was applied to waterproof joints and prevent leaks.

- Installation: Pipes were laid in trenches, often with gravel bedding to minimize soil contact and rot.

Did You Know?

Some pipes exceeded 3 feet in diameter and transported millions of gallons daily. Boston’s Cochituate Aqueduct (1848) famously used wooden pipes, while photographic records from the 1910s–20s show crews laying vast networks in logging towns like Everett, Washington.

Pros and Cons: Why Wood Ruled (Until It Didn’t)

Advantages:

- Cost-Effective: Wood was cheaper and more accessible than iron in forested areas.

- Insulation: Wood resisted temperature extremes, preventing freezing in cold climates.

- Low-Tech Maintenance: Repairs could be made locally with basic carpentry tools.

Challenges:

- Rot and Decay: Buried pipes deteriorated over 10–25 years, especially in damp soil.

- Limited Pressure Capacity: Wood couldn’t compete with iron for high-pressure systems.

- Fire Risk: Dry pipes were vulnerable to wildfires or sparks from nearby railways.

By the 1920s, these flaws—paired with advancements in iron and concrete—led to wood’s decline. Yet many systems operated into the mid-20th century, and relic pipes still surface during urban excavations today.

Rare Glimpses: Photos From the Golden Age of Wooden Pipes

Photographs from the 1900s–1920s reveal the scale and labor behind wooden pipelines:

- Hollowed Log Systems: Black-and-white images show workers hand-carving massive trunks in sawmill yards.

- Stave Pipe Factories: Assembly lines with stacks of finished staves and steam-powered bending machines.

- Installation Crews: Teams laying pipes across rugged terrain, often in remote mining or farming regions.

[Note: While we can’t embed photos here, search terms like “1900s wooden water pipes” or “vintage stave pipe photos” yield remarkable archival results from libraries like Getty or Shorpy.]

Legacy: Wooden Pipelines’ Impact on Modern Infrastructure

Wooden pipelines were a stepping stone to today’s water systems. They proved that gravity-fed networks could supply cities without pumps, inspired standardized pipe sizing, and even influenced the design of early hydropower systems. Though obsolete, relics of these pipes are preserved in museums, such as the San Diego History Center (which displays redwood stave pipes), or buried beneath cities like Seattle as archaeological curiosities.

Conclusion: Celebrating a Bygone Engineering Marvel

Wooden water pipelines represent an era of grassroots innovation—where communities turned local resources into lifelines. Though fleeting, their impact shaped how we design resilient, sustainable water networks today. Next time you turn on a tap, remember the humble wooden pipes that once made modern hydration possible!

SEO Keywords: Wooden water pipelines, turn-of-the-century water transport, hollowed tree trunk pipes, stave-built wooden pipes, 1900s water infrastructure, historical wooden plumbing, vintage water systems, early 20th century engineering.

By combining historical insights with vivid details, this article targets history buffs, engineering enthusiasts, and SEO algorithms alike—ensuring this forgotten innovation flows back into public memory.