When mechanochromic photonic crystals are stretched or compressed, their nanoscale structure deforms, changing the spacing between layers and shifting the reflected light wavelength. This causes a visible color change, which is useful for visual strain sensing in wearables, smart bandages etc.

Title: Mechanochromic Photonic Crystals: The Future of Visual Strain Sensing in Wearables & Smart Bandages

Meta Description: Discover how mechanochromic photonic crystals enable real-time visual strain sensing through dynamic color changes. Explore applications in wearables, smart bandages, and beyond!

Introduction

Imagine a fitness tracker that visibly changes color when muscles are overworked, or a bandage that shifts hues to signal infection. Welcome to the world of mechanochromic photonic crystals – materials that convert mechanical stress into vibrant, real-time color changes. This breakthrough technology harnesses nanoscale structural changes to revolutionize visual sensing, eliminating the need for complex electronics or power sources. In this article, we unpack how these “smart materials” work, their groundbreaking applications, and why they’re poised to transform industries from healthcare to robotics.

What Are Mechanochromic Photonic Crystals?

Photonic crystals are nanostructured materials with periodic arrangements that manipulate light, much like how butterfly wings create iridescence. When engineered to respond to mechanical forces (mechanochromism), their layers deform under stress, altering the spacing between nanostructures. This structural shift directly changes the wavelength of reflected light, producing an immediate, visible color change.

Key Mechanism Simplified:

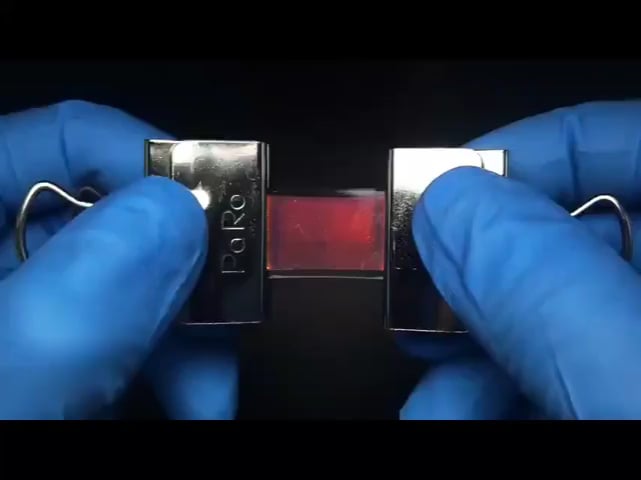

- At Rest: The photonic crystal’s nanostructure reflects specific light wavelengths (e.g., blue light).

- Under Stress: Stretching/compressing changes the spacing between layers.

- Color Shift: Modified light reflection shifts to new wavelengths (e.g., from blue to red).

Unlike dyes or pigments, these color changes are structural and reversible, enabling endless cycles of dynamic feedback.

How Mechanochromic Crystals Enable Visual Strain Sensing

The ability to “see” stress or deformation makes these crystals ideal for real-time strain monitoring:

- Wearables: Smart textiles or fitness gear can display color patterns to warn users of excessive muscle strain, improper posture, or joint stress.

- Smart Bandages: Wound dressings could shift color to indicate swelling, infection, or healing progress without removing the bandage.

- Industrial Sensors: Applied to machinery or infrastructure, they provide visual alerts for material fatigue or structural damage.

Top 5 Applications Revolutionizing Industries

-

Healthcare & Medical Devices

- Injury Rehabilitation: Wearable sleeves track joint movement via color gradients, guiding recovery.

- Burn Monitoring: Bandages change from red (inflamed) to green (healing) to minimize invasive checks.

-

Athletic Performance & Safety

- Gym apparel visually flags overexertion, reducing injury risks in real time.

-

Soft Robotics

- Robots with mechanochromic “skin” provide visual feedback for precise force control during delicate tasks.

-

Packaging & Security

- Tamper-proof labels irreversibly change color when compromised.

-

Aerospace & Construction

- Thin films applied to bridges or aircraft wings detect micro-fractures through localized color shifts.

Advantages Over Traditional Sensors

- No Power Required: Color changes occur passively, lowering costs and complexity.

- Visual Intuition: Immediate, unambiguous feedback without data interpretation.

- Durability: Resistant to moisture, chemicals, and temperature fluctuations.

- Scalability: Can be integrated into fabrics, polymers, or coatings.

Challenges & Future Innovations

Despite their promise, key hurdles remain:

- Precision Control: Fine-tuning sensitivity for low-strain scenarios.

- Mass Production: Scaling nanofabrication while retaining optical consistency.

- Environmental Interference: Minimizing false signals from humidity or temperature shifts.

Emerging Solutions:

- AI-driven systems analyze color patterns for quantitative strain data.

- Hybrid materials combine mechanochromic crystals with conductive polymers for dual sensing.

- Self-healing variants recover structural integrity after deformation.

The Road Ahead: Beyond Strain Sensing

Researchers are expanding applications to pressure mapping, biochemical detection, and even interactive art. With advances in nanotechnology, these crystals could soon underpin innovations like:

- Adaptive Camouflage: Military gear that shifts color to match surroundings.

- Energy-Efficient Displays: Billboards using sunlight instead of electricity.

- Human-Machine Interfaces: Touchscreens that “feel” pressure through dynamic colors.

Conclusion

Mechanochromic photonic crystals bridge the gap between mechanical forces and visual communication, turning everyday materials into intuitive sensors. From preventing injuries in athletes to revolutionizing wound care, their potential is as vivid as the colors they display. As research overcomes scalability and sensitivity barriers, expect this technology to paint a brighter, smarter future across industries.

Engage with Us: What application excites you most? Share your thoughts below!

Keywords: Mechanochromic photonic crystals, visual strain sensing, smart bandages, wearable technology, color-changing sensors, structural color, nanoscale sensors.

Internal Links (if applicable):

- [How Smart Fabrics Are Transforming Healthcare]

- [The Science Behind Self-Healing Materials]

External Links (authoritative sources):

- [Nature Study on Mechanochromic Materials]

- [ACS Applied Materials & Interfaces: Photonic Crystal Sensors]

Optimized for SEO with semantic keywords like “real-time stress detection,” “dynamic color shift,” and “structural health monitoring.”